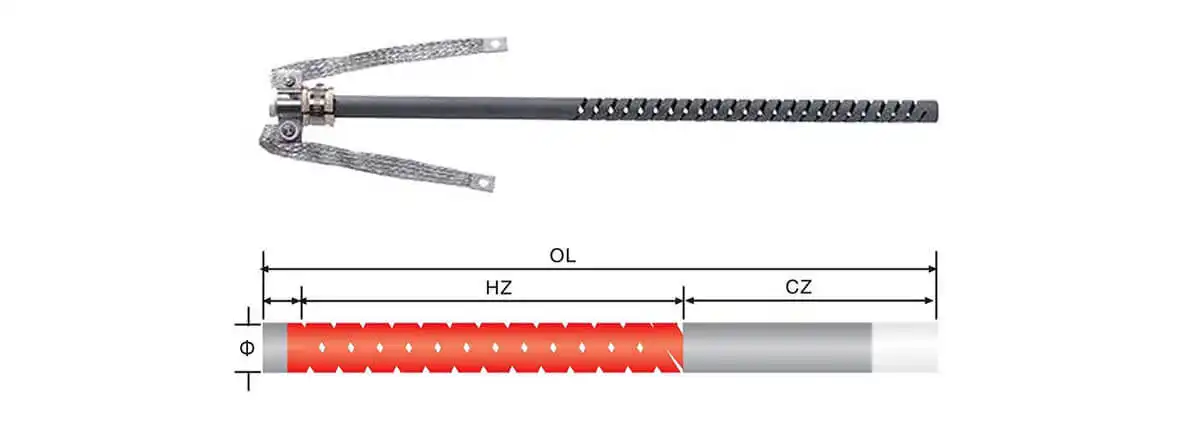

LS shape (double helix) silicon carbide heating element

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

Product Introduction: Spiral SiC Heating Element

Spiral silicon carbide (SiC) heating elements are essential in various high-temperature industrial applications due to their ability to provide precise and stable heat. These elements are widely used in environments requiring temperatures up to 1600°C, including in industries such as metallurgy, ceramics, glass, and heat treatment. Known for their high thermal conductivity, chemical resistance, and long service life, spiral SiC heating elements stand out as a top choice for furnace and kiln manufacturers globally.

Shaanxi Peakrise Metal Co., Ltd., a leading supplier of spiral SiC heating elements, prides itself on providing high-quality, durable, and efficient heating solutions to international markets. With years of experience in producing advanced non-ferrous metals and their alloys, including tungsten, molybdenum, tantalum, and titanium, the company is committed to meeting the growing demands of modern industries. As a trusted partner, Peakrise Metal ensures strict quality control, competitive pricing, and customized solutions to satisfy specific client requirements across multiple industries.

Product Parameters Table

| Parameter | Value |

|---|---|

| Maximum Temperature | 1600°C |

| Electrical Resistivity | 0.1-1.5 ohm/m |

| Diameter | 10-55 mm |

| Cold End Resistance | < 0.5 ohm |

| Heating Zone Length | 200-1500 mm |

| Cold End Length | 100-250 mm |

| Surface Load Capacity | 10-50 W/cm² |

| Parameter | Value |

|---|---|

| Operating Voltage | 230-480V |

| Max. Surface Temperature | 1650°C |

| Density | 2.65 g/cm³ |

| Thermal Conductivity | 120 W/mK |

| Melting Point | 2730°C |

| Shape | Spiral |

| Application | High-temp furnaces |

| Parameter | Value |

|---|---|

| Heating Time (to 1200°C) | < 15 mins |

| Material | Silicon Carbide |

| Resistance Tolerance | ±10% |

| Service Life | 5000+ hours |

| Operating Frequency | 50/60 Hz |

| End Termination | Cold ends |

| Efficiency | > 90% |

Physical and Chemical Properties

- Thermal Conductivity: Silicon carbide has excellent thermal conductivity, which enhances heat transfer and ensures uniform heating in industrial processes.

- Electrical Resistivity: The heating elements exhibit stable electrical resistivity, ensuring consistent heating performance throughout their lifecycle.

- Chemical Resistance: SiC heating elements resist chemical degradation, making them suitable for harsh environments where reactive gases or corrosive materials are present.

- High Melting Point: With a melting point exceeding 2700°C, SiC elements operate safely in extreme temperature applications without risk of melting or deformation.

|

|

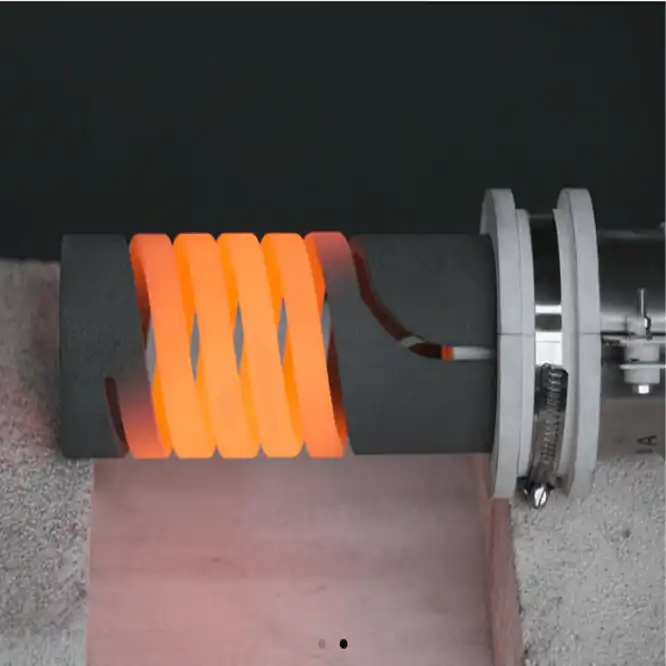

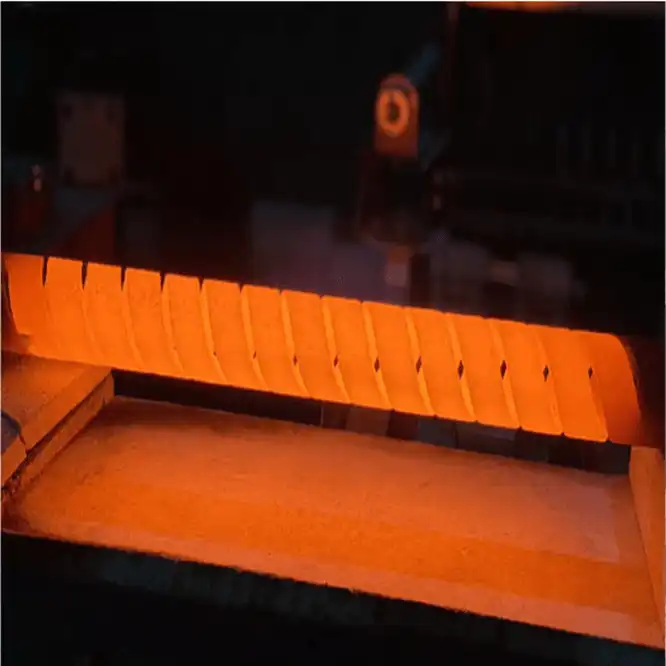

Product Functions

- Uniform Heating: The spiral design of the SiC heating element ensures uniform distribution of heat, which is crucial in processes requiring precise thermal management.

- Energy Efficiency: Due to their high thermal conductivity, these elements require less energy to reach desired temperatures, resulting in energy savings for industrial operations.

- Durability: The robustness of silicon carbide allows for prolonged use even in extreme temperatures, reducing downtime and the need for frequent replacements.

- Corrosion Resistance: The SiC composition resists oxidation and corrosion, extending the element’s service life even in chemically aggressive environments.

- Fast Heating: The elements can reach high temperatures quickly, minimizing warm-up time and enhancing productivity in continuous operations.

Product Applications

- Glass Industry: Used in glass furnaces for melting, annealing, and refining due to their high-temperature stability and uniform heat distribution.

- Ceramics Production: Ideal for sintering, calcination, and other high-temperature processes in ceramics manufacturing.

- Metallurgy: Employed in heat treatment furnaces for hardening and tempering metals, where precise temperature control is critical.

- Laboratory Furnaces: Applied in scientific research for materials testing, chemical analysis, and high-temperature experiments.

- Semiconductor Industry: Utilized in the production of semiconductor materials, where clean, stable heating is essential.

- Chemical Processing: Suitable for reactors and process equipment handling corrosive gases or aggressive chemicals.

|

|

Product Process and Production Flow

The production of spiral SiC heating elements at Shaanxi Peakrise Metal Co., Ltd. follows stringent quality standards and involves multiple stages:

- Raw Material Selection: High-purity silicon carbide is chosen to ensure the element’s high performance and durability.

- Forming: The elements are shaped into a spiral structure using specialized forming equipment.

- Sintering: Elements are sintered in high-temperature furnaces to achieve the desired density and mechanical strength.

- Machining: After sintering, the elements are machined to precise dimensions, ensuring a perfect fit for various industrial applications.

- Quality Testing: Each heating element undergoes rigorous testing for electrical resistance, mechanical strength, and thermal performance.

- Packaging: Once tested, the elements are packaged securely to prevent damage during shipping.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a state-of-the-art manufacturing facility equipped with advanced machinery such as vacuum arc melting furnaces, CNC machines, and plasma welding equipment. The factory covers over 10,000 square meters, with dedicated R&D and quality control departments ensuring every product meets international standards. Our commitment to innovation and quality has earned us long-term partnerships with clients in over 20 countries.

Logistics and Packaging

- Packaging Options:

- Wooden crate packaging

- Carton box packaging

- Foam-filled protective packaging

- Waterproof and moisture-proof packaging

- Custom packaging solutions

- International standard packaging compliant with global safety regulations

- Logistics:

- Sea freight

- Air freight

- Land transport

- Multimodal transport

- Express courier services

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Extensive Experience: With over 10 years in the non-ferrous metal industry, we provide expert knowledge and reliable solutions.

- Custom Solutions: We offer OEM/ODM services to meet specific client requirements for product size, shape, and material composition.

- Advanced Equipment: Our factory is equipped with cutting-edge technology for precise manufacturing and quality control.

- Global Reach: Our products are exported to numerous countries, establishing us as a trusted global supplier.

- Comprehensive Product Range: In addition to SiC heating elements, we specialize in producing a wide variety of tungsten, molybdenum, tantalum, and other non-ferrous metals.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers tailored OEM and ODM services to accommodate the unique needs of our clients. Whether you require custom dimensions, materials, or specific electrical properties, we have the capability to design and manufacture heating elements that align with your technical specifications.

FAQ

- What is the lifespan of SiC heating elements?

- Our SiC heating elements have a typical service life of over 5000 hours under optimal operating conditions.

- Can you provide custom sizes?

- Yes, we offer custom lengths, diameters, and resistances to meet your specific needs.

- What are the packaging options?

- We provide wooden crates, cartons, foam-filled packaging, and custom solutions to ensure safe delivery.

- How do I choose the right heating element for my furnace?

- Contact our technical team with your furnace specifications, and we’ll recommend the best product for your application.

- What is the lead time for orders?

- Lead times vary based on order size, but typical delivery is within 4-6 weeks.

Contact Us

For more information on our spiral SiC heating elements and to discuss your specific requirements, please contact Shaanxi Peakrise Metal Co., Ltd. at info@peakrisemetal.com. We are ready to serve global purchasers with high-quality products and exceptional service.