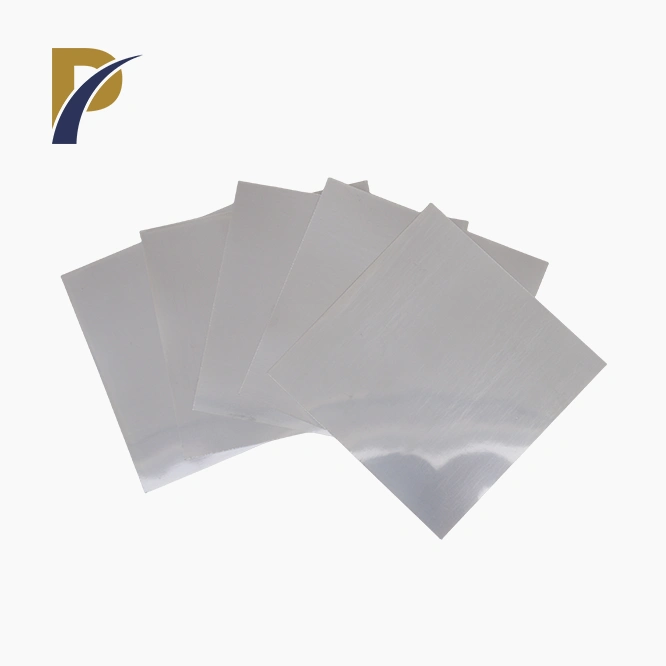

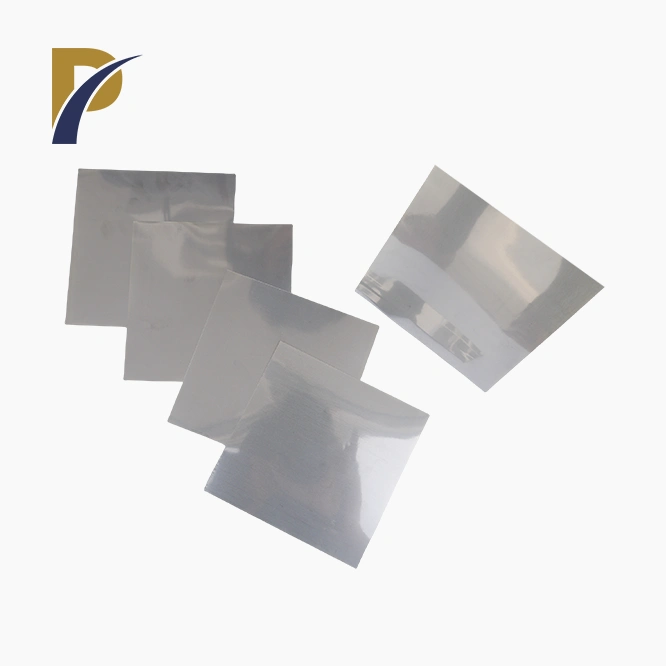

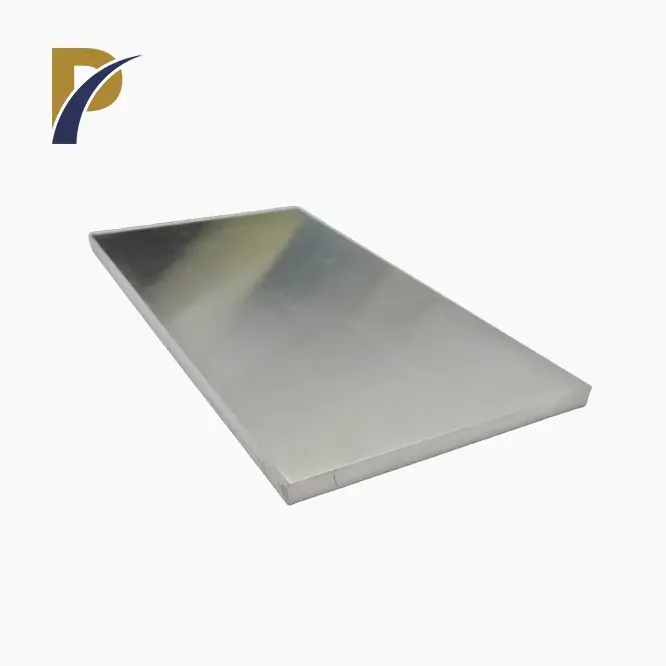

molybdenum sheet/plate

W Content: 50% (wt%)

Mo Content: 50% (wt%)

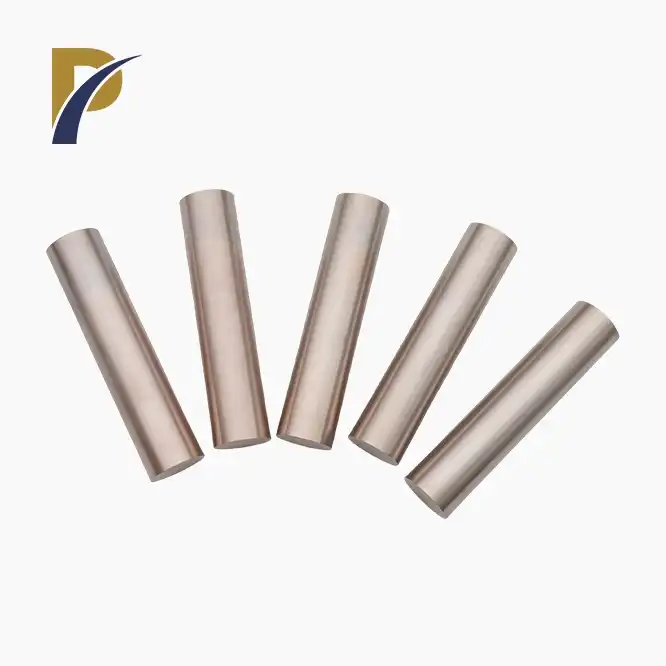

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

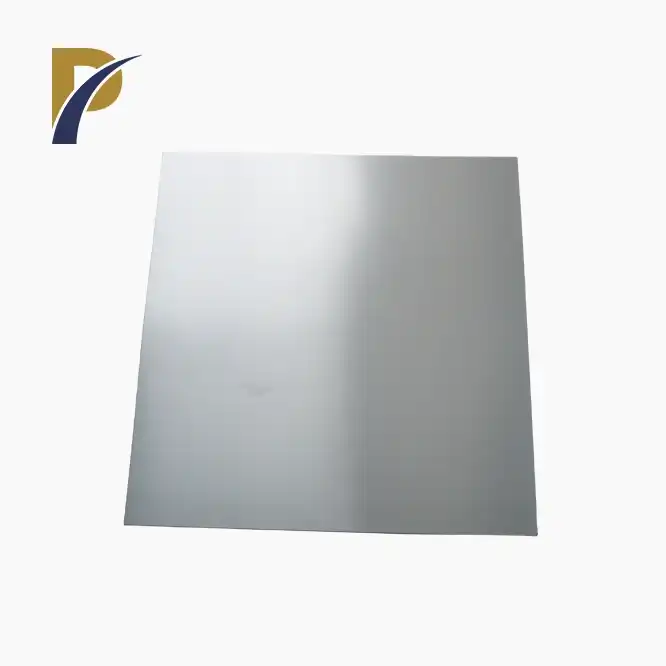

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Molybdenum Sheet/Plate Product Introduction

Product Introduction

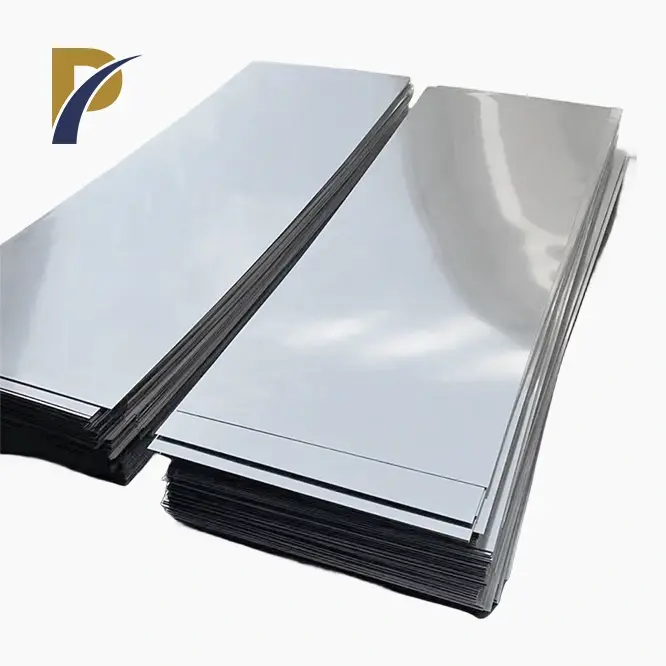

Molybdenum sheets and plates are essential materials in the metalworking and high-temperature industries, known for their outstanding performance under extreme conditions. Molybdenum offers exceptional thermal and electrical conductivity, high melting point, and resistance to corrosion, making it ideal for high-temperature furnace components, aerospace parts, and the electronics industry. As a leading supplier, Shaanxi Peakrise Metal Co., Ltd. specializes in providing high-quality molybdenum sheets and plates to meet the needs of industries worldwide. Our molybdenum products are made from 99.95% pure molybdenum and are crafted to meet the stringent demands of high-temperature applications.

Since our establishment, Shaanxi Peakrise Metal Co., Ltd. has been committed to the development, research, and global distribution of non-ferrous metals such as tungsten, molybdenum, tantalum, niobium, and titanium. Our products, including molybdenum sheets and plates, are manufactured to meet international standards and are exported to countries such as the United States, South Korea, Germany, and Iran. With a reputation for quality, we are recognized as a trusted supplier by our global clientele.

Product Parameters

| Description | Grade | Density g/cm3 |

Size (mm) | Application | |

| Large Size | High temperature molybdenum plate, molybdenum alloy sheet | Mo-La TZM |

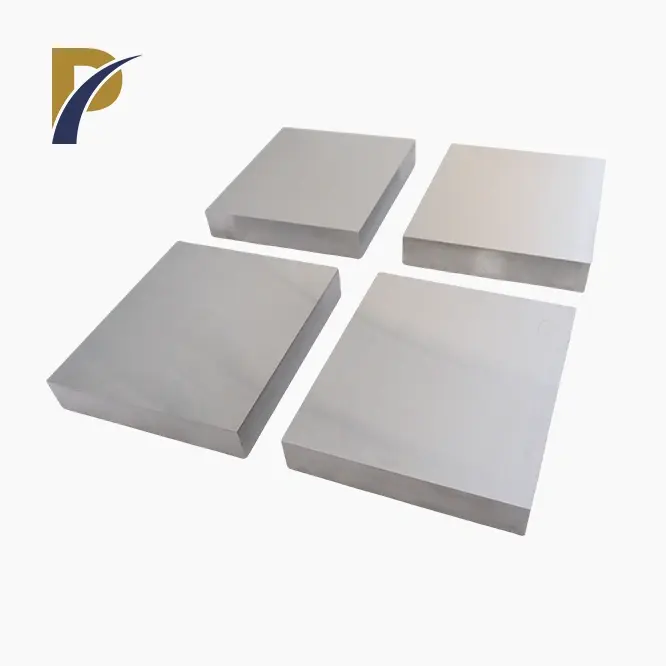

>9.8 | (20-40) x (90-240) x (200-600) | Good high temperature performance and machinability |

| High purity molybdenum sheet | Mo | 10.2 | Suitable for rolling pure molybdenum sheet | ||

| Small Size | High purity molybdenum sheet | Mo | 16 x 16 x 160 | Suitable for rolling molybdenum foil and molybdenum disc | |

|

|

|

Physical and Mechanical Properties

Molybdenum sheets and plates have remarkable properties that make them suitable for a wide range of applications. Their high density and thermal conductivity ensure effective heat dissipation, while the high melting point enables usage in environments with extreme temperatures. The material’s excellent corrosion resistance in most conditions ensures longevity, even in harsh environments. The high strength and elasticity modulus of molybdenum further enhance its stability in demanding applications.

| Quantitative analysis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | N | Mg | Fe | Sn | Al | Cd | Ca | Bi | Si | P | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.003 | 0.002 | 0.005 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.001 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | C | O | Ni | Sb | Pb | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.01 | 0.003 | 0.003 | 0.0005 | 0.0001 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Purity(Metallic Base) Mo≥99.95% | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Applications

- High-Temperature Furnaces: Molybdenum’s heat-resistant properties make it perfect for use as heating elements, shielding materials, and structural components in high-temperature vacuum furnaces.

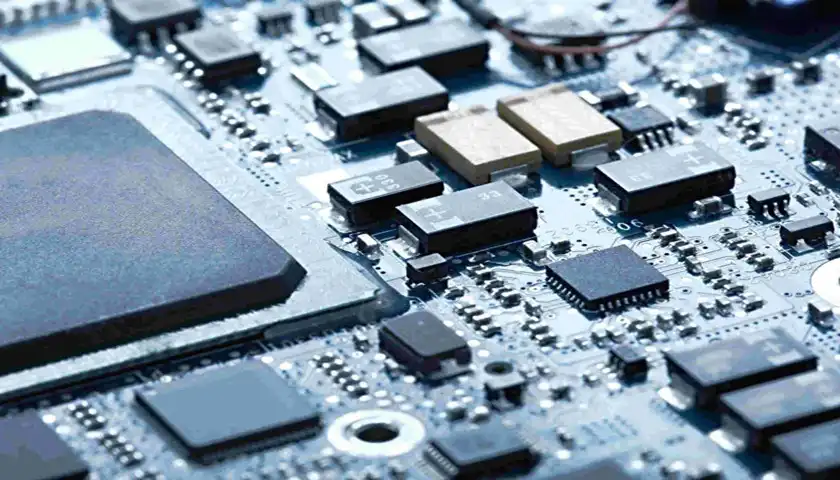

- Semiconductor Industry: Molybdenum sheets are used in sputtering targets, which play a crucial role in the semiconductor and thin-film industries due to their superior electrical properties.

- Aerospace Components: Molybdenum’s strength and ability to maintain structural stability at high temperatures make it a preferred material for aerospace applications such as turbine parts and heat shields.

- Nuclear Energy Industry: Molybdenum’s resistance to radiation damage and high temperatures allows it to be used in nuclear reactors and other radiation-prone environments.

- Medical Equipment: Molybdenum sheets are used in medical diagnostic equipment such as X-ray machines, thanks to their excellent radiographic properties.

|

|

Product Process and Production Flow

Our production process for molybdenum sheets and plates follows strict quality control guidelines to ensure each product meets international standards.

- Material Sourcing: We use 99.95% pure molybdenum ore, ensuring the highest quality for our products.

- Sintering and Melting: Molybdenum is processed through intermediate frequency sintering and vacuum arc melting, ensuring consistent purity and structure.

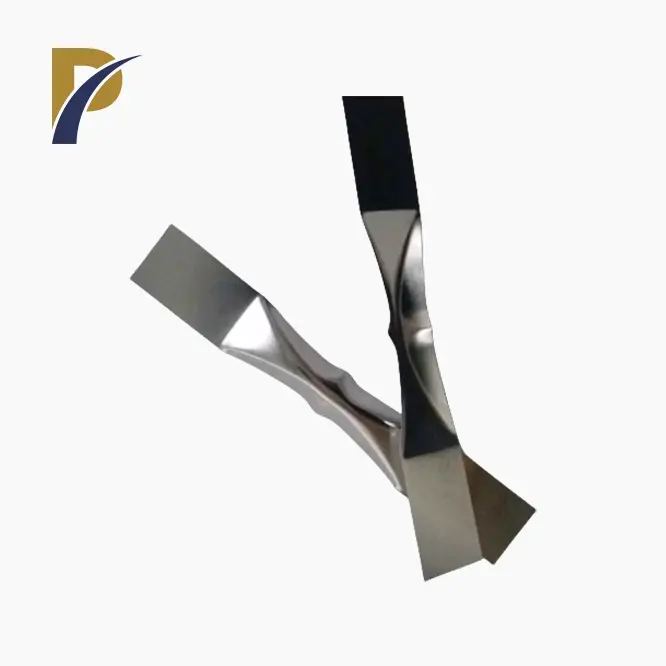

- Rolling and Cutting: The molybdenum is then rolled and cut to the desired thickness and size, ensuring precision and uniformity in every sheet and plate.

- Annealing: Sheets undergo vacuum annealing to enhance their strength and durability, making them suitable for high-temperature applications.

- Surface Treatment: Finally, the sheets are polished or chemically cleaned, depending on customer requirements.

|

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. is equipped with state-of-the-art production facilities, including vacuum arc melting furnaces, laser cutters, and CNC machines. Our manufacturing capabilities allow us to produce a wide range of non-ferrous metal products, including molybdenum sheets and plates. Our commitment to quality is reflected in our ISO 9001 certification, ensuring that every product meets the highest industry standards.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Packaging:

- Wooden crates for secure transport

- Cardboard boxes for smaller quantities

- Foam-filled for added protection

- Waterproof and moisture-proof packaging for high-humidity environments

- Custom packaging available upon request, adhering to international standards

- Logistics:

- Sea freight for large orders

- Air freight for urgent deliveries

- Land transport for regional clients

- Multi-modal transport combining sea, air, and land

- Express courier services for smaller shipments

|

|

|

|

|

|

|

|

Why Choose Us?

- Comprehensive Experience: With over a decade of experience in non-ferrous metals, we are industry leaders in manufacturing high-quality molybdenum products.

- Advanced Technology: Our state-of-the-art production equipment ensures the highest precision and quality in every product we deliver.

- Global Reach: Our products are exported to countries worldwide, establishing long-term relationships with satisfied customers.

- Custom Solutions: We offer OEM/ODM services, allowing for customized solutions that meet the specific needs of our clients.

- Customer Support: We pride ourselves on excellent customer service, offering technical support and consultation throughout the purchasing process.

FAQ

- What are the standard thicknesses for molybdenum sheets?

We offer thicknesses ranging from 0.1mm to 50mm, but custom thicknesses can be manufactured based on your requirements. - What surface treatments are available for molybdenum sheets?

We provide polished, chemically cleaned, or rolled surface finishes. - What is the lead time for orders?

Standard products are typically available for immediate shipment. For custom orders, lead times vary depending on specifications but generally range from 2 to 4 weeks. - Can you provide samples?

Yes, we offer free samples upon request. - What are your payment terms?

We accept various payment methods, including bank transfer, letter of credit, and PayPal.

Contact Us

Are you looking for high-quality molybdenum sheets or plates? Contact Shaanxi Peakrise Metal Co., Ltd. today to learn how we can meet your needs. With our years of expertise, top-notch production capabilities, and commitment to quality, we are your reliable partner for all your molybdenum product needs. Reach out to us at info@peakrisemetal.com for a quote or more information. We look forward to working with you!