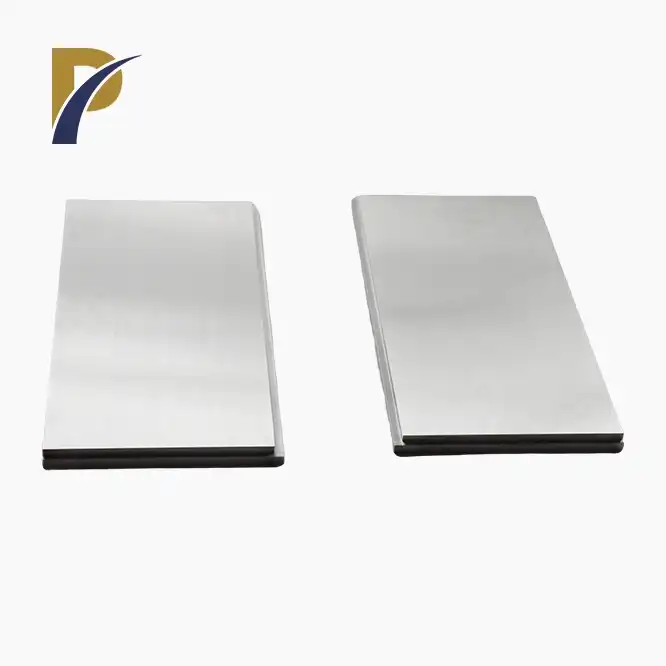

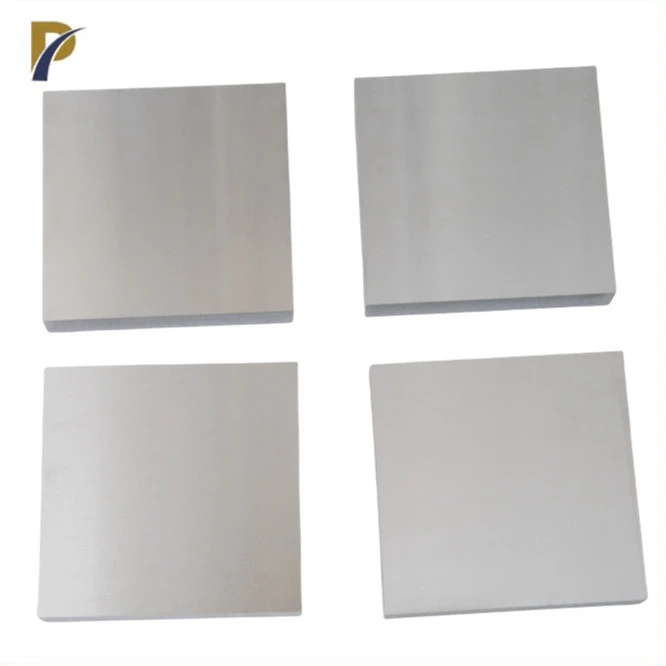

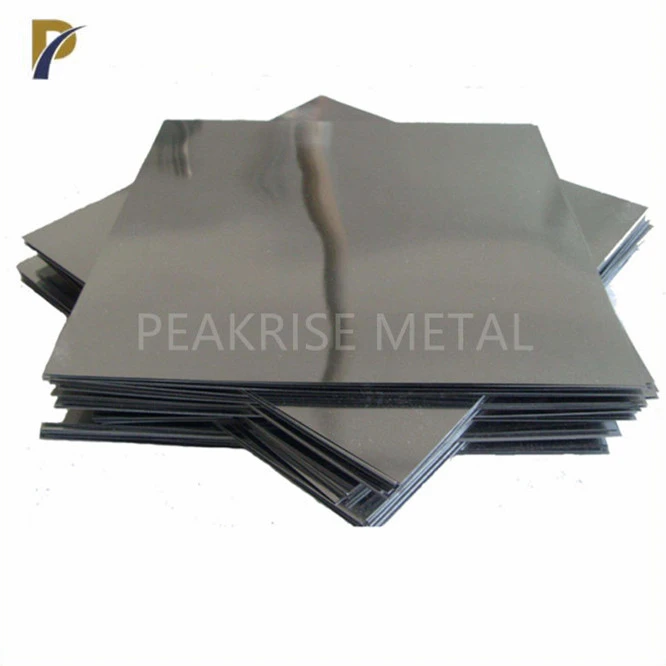

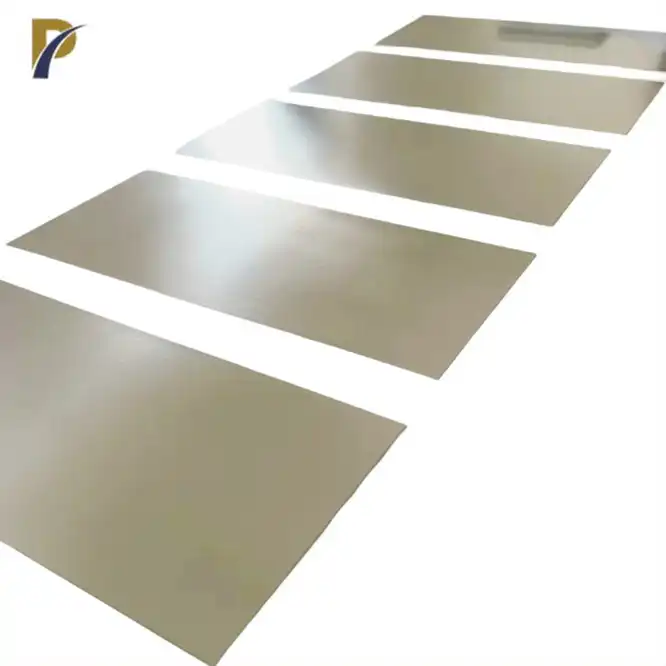

molybdenum plate and sheet

W Content: 50% (wt%)

Mo Content: 50% (wt%)

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Molybdenum Plate and Sheet Product Introduction

At Shaanxi Peakrise Metal Co., Ltd., we specialize in manufacturing high-quality molybdenum plate and sheet products. Our molybdenum plates and sheets are renowned for their strength, durability, and exceptional heat and corrosion resistance, making them indispensable in industries such as electronics, aerospace, and chemical processing. Molybdenum, with its high melting point of 2620°C, exhibits excellent performance in extreme environments, providing stability and efficiency where other metals may fail.

As a leading supplier of molybdenum products, Shaanxi Peakrise Metal Co., Ltd. leverages extensive experience in producing non-ferrous metals to meet the demanding requirements of global industries. Our plates and sheets are used for high-temperature structural applications, heating elements, furnace parts, and more. We offer a wide range of sizes and thicknesses, customizable to your specific needs, ensuring optimal performance for any industrial use. Whether you are looking for standard plates or need a customized solution, we have the expertise and capacity to fulfill your requirements with precision.

With over a decade of development in the non-ferrous metal industry, Shaanxi Peakrise Metal Co., Ltd. prides itself on delivering superior quality molybdenum plates and sheets to international markets, ensuring reliable, consistent products that meet the highest industry standards.

Product Parameters Table

| Parameter | Value | Tolerance |

|---|---|---|

| Thickness | 0.1 mm – 50 mm | ±0.05 mm |

| Width | Up to 600 mm | ±1.0 mm |

| Length | Up to 3,000 mm | ±2.0 mm |

| Density | 10.2 g/cm³ | N/A |

| Purity (Mo) | ≥ 99.95% | N/A |

|

|

|

Physical and Mechanical Properties

Molybdenum boasts outstanding physical and mechanical properties that contribute to its performance in demanding environments. These include:

- High Melting Point: With a melting point of 2620°C, molybdenum performs well in high-temperature applications, ensuring long-term reliability.

- Corrosion Resistance: Molybdenum is highly resistant to corrosion in harsh chemical environments, making it ideal for chemical processing applications.

- Thermal Conductivity: Its excellent thermal conductivity ensures efficient heat transfer, particularly in electronics and furnace components.

- Low Thermal Expansion: Molybdenum’s low thermal expansion minimizes distortion at high temperatures, improving product longevity.

- High Density and Strength: With a density of 10.2 g/cm³ and exceptional strength, molybdenum is a robust solution for structural components under extreme conditions.

| Element | Composition % | ||

| Grade | |||

| 361(Mo-1) | 364(TZM) | 366(Mo-30%W) | |

| C | 0.01 max. | 0.01~0.04 | 0.03 max. |

| O,max. | 0.007 | 0.03 | 0.0025 |

| N,max. | 0.002 | 0.002 | 0.002 |

| Fe, max. | 0.01 | 0.01 | 0.01 |

| Ni, max. | 0.005 | 0.005 | 0.005 |

| Si, max. | 0.01 | 0.005 | 0.01 |

| Ti | 0.4~0.55 | ||

| W | 27~33 | ||

| Zr | 0.06~0.12 | ||

| Mo | Remain | Remain | Remain |

Product Functions

Our molybdenum plates and sheets serve a variety of industrial functions, each optimized by their unique properties:

- High-Temperature Stability: The high melting point of molybdenum makes it ideal for furnace and aerospace components that must endure extreme heat without degradation.

- Corrosion Resistance: In chemical processing, molybdenum’s resistance to corrosive substances extends the life of equipment exposed to acids and other reactive chemicals.

- Durable Electrical Conductor: Its use in the electronics industry is widespread due to its excellent electrical conductivity, which ensures efficient and stable power transmission.

- Heat Shielding: Molybdenum’s thermal properties make it a superior heat shield in high-temperature applications such as spacecraft and industrial furnaces.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

The high-performance attributes of molybdenum plates and sheets have led to their application across multiple industries. Key areas of use include:

- Aerospace: Used in the production of components that require high strength and temperature resistance, such as turbine blades and structural parts.

- Electronics: Applied in semiconductor and display technologies for their conductivity and stability under high thermal loads.

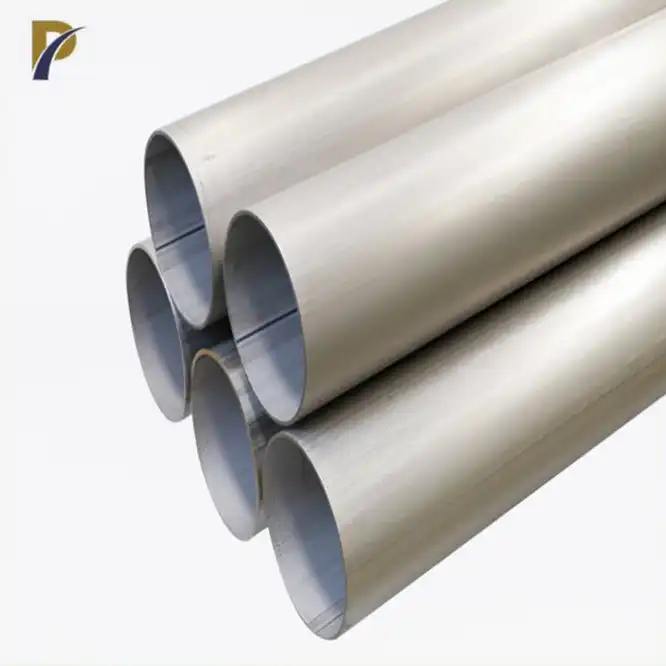

- Chemical Processing: Ideal for use in equipment exposed to harsh chemical environments, including reactors and piping systems.

- Glass and Ceramics: Involved in the manufacture of glass and ceramic components due to its resistance to high temperatures and corrosive substances.

- Energy: Used in nuclear reactors and other energy-generation technologies where stability and resistance to thermal creep are crucial.

Product Process and Production Flow

At Shaanxi Peakrise Metal Co., Ltd., the manufacturing process for molybdenum plates and sheets is handled with precision and expertise:

- Material Sourcing: We use only the highest purity molybdenum to ensure superior performance.

- Melting and Refining: The molybdenum is melted in our state-of-the-art vacuum arc furnaces to remove impurities.

- Rolling: The molten molybdenum is rolled into sheets and plates of varying thicknesses using advanced rolling mills.

- Annealing: To enhance durability, our molybdenum sheets undergo vacuum annealing for uniform grain structure.

- Finishing and Inspection: Each plate and sheet is finished to precise tolerances and inspected rigorously for defects before shipment.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. boasts a comprehensive production facility equipped with advanced machinery. Our facilities include vacuum arc melting furnaces, rolling mills, and CNC machines that allow us to produce molybdenum plates and sheets to exacting specifications. We pride ourselves on a robust quality control system and the ability to provide custom solutions for a wide range of industrial needs.

|

|

|

|

Logistics and Packaging

We offer multiple packaging solutions to ensure the safe delivery of our molybdenum plates and sheets, including:

- Wooden box packaging

- Foam-filled packaging

- Waterproof and moisture-proof packaging

- Customized packaging

- All packaging complies with international standards

|

|

|

|

|

|

|

|

Logistics options include:

- Sea transport

- Air transport

- Land transport

- Multimodal transport

- Courier services

Why Choose Us?

- Extensive Experience: With over a decade in the non-ferrous metal industry, we have established ourselves as a trusted supplier of molybdenum products.

- Global Reach: Our products are exported to markets worldwide, including the U.S., Germany, South Korea, and Australia.

- Comprehensive Services: We offer customized OEM/ODM services, allowing us to tailor products to meet your specific requirements.

- Advanced Facilities: Our cutting-edge production equipment ensures high-quality manufacturing and quick turnarounds.

- Strong Customer Relationships: We have built long-term partnerships with clients globally, based on trust and product excellence.

FAQ

-

What is the purity of your molybdenum plates? Our molybdenum plates and sheets are ≥ 99.95% pure.

-

Can I request custom sizes? Yes, we offer customized dimensions to meet your specific needs.

-

How do you ensure product quality? Each batch undergoes stringent quality control, including inspections and testing at multiple stages.

-

What is your lead time for orders? Lead times vary depending on order size but generally range from 2 to 6 weeks.

-

Do you provide technical support? Yes, we offer full technical support to help with product selection and application.

Contact Us

Ready to place an order or have more questions? Contact us today to discuss your molybdenum plate and sheet needs. At Shaanxi Peakrise Metal Co., Ltd., we are committed to providing high-quality non-ferrous metal products tailored to your industrial requirements. Email us at info@peakrisemetal.com to get started.

_1734664661802.webp)

_1734664661485.webp)

_1734664661745.webp)