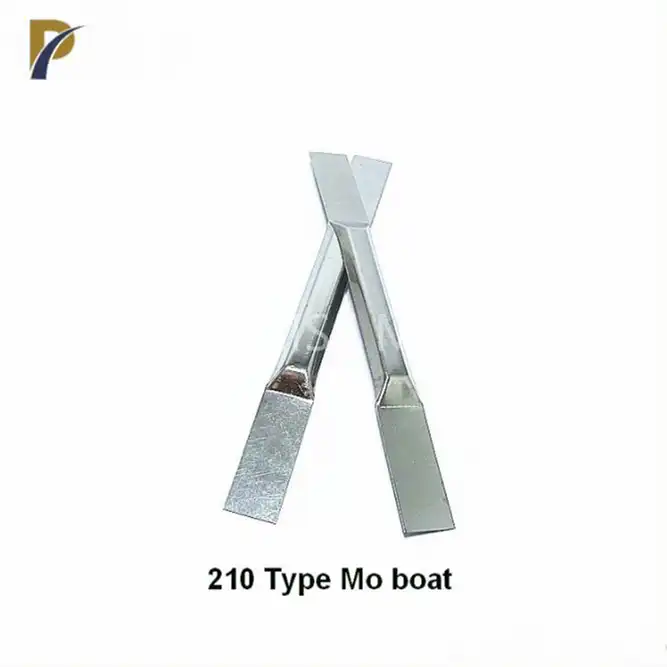

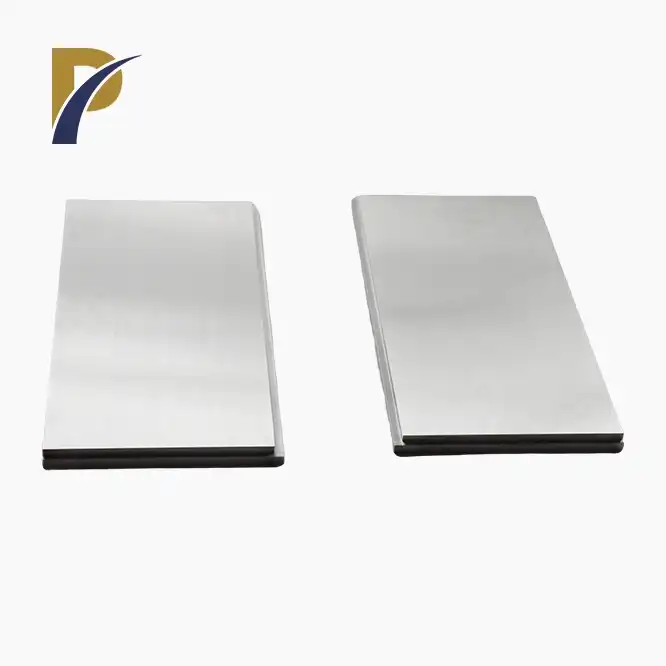

molybdenum thermal boat

Thickness: 0.3,0.5mm

Size: 210 215 310 315 308 320 525 Etc.

Surface: Bright

Process: Stamping

Shape :Boat

Melting Point : 2610℃

Boiling Point: 5560℃

Density: 10.2g/cm3

Application: Evaporation Coating, vacuum evaporation, coating technology, electronics industry, power engineering, capacitor sintering, thermocouple shells, etc.

PRODUCT DESCRIPTION

Product Overview

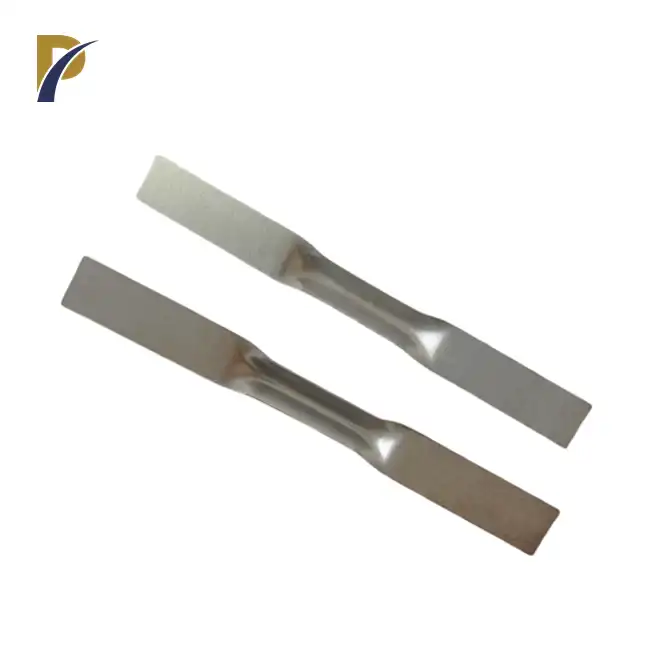

Molybdenum thermal boats are essential components for high-temperature applications, particularly in vacuum evaporation, thin film deposition, and other industrial heating processes. Manufactured from high-purity molybdenum and molybdenum alloys such as Mo-La (molybdenum-lanthanum) and TZM (titanium-zirconium-molybdenum), these boats offer exceptional heat resistance, high melting points, and excellent chemical stability.

With precise engineering, our molybdenum thermal boats ensure uniform heating and efficient material evaporation, making them ideal for use in vacuum furnaces, semiconductor production, and optical coating industries.

Technical Specifications

| Model | Thickness (mm) | Width (mm) | Length (mm) | Material |

|---|---|---|---|---|

| #207 | 0.2 | 7 | 100 | Pure Mo |

| #215 | 0.2 | 15 | 100 | Mo-La |

| #308 | 0.3 | 8 | 100 | TZM |

| #310 | 0.3 | 10 | 100 | Pure Mo |

| #315 | 0.3 | 15 | 100 | Mo-La |

| #413 | 0.4 | 13 | 50 | TZM |

| #525 | 0.5 | 25 | 78 | Pure Mo |

Customized dimensions and designs are available upon request.

|

|

|

Key Features

High Melting Point: Molybdenum boats can withstand extreme temperatures up to 2,600°C.

Superior Thermal Conductivity: Ensures even heat distribution for efficient evaporation.

Corrosion Resistance: Stable in vacuum environments and resistant to chemical reactions.

High Density and Strength: Ideal for demanding industrial applications.

Customizable Designs: Available in various shapes, including flat-bottom, V-shaped, and round-bottom designs.

Precision-Engineered Molybdenum Alloy Boats Tailored to Your Needs!

At Peakrise Metal, your requirements take top priority. With over a decade of expertise, we transform complex ideas into practical solutions through our precision-engineered molybdenum alloy boats. From initial design to detailed specification adjustments, every stage of our manufacturing process is customized to meet your exact demands.

Customization Options for Molybdenum Alloy Boats:

-

Size and Shape: Customize the length, width, and overall design to fit specific application needs, ensuring compatibility with different equipment and operating conditions.

-

Purity: Select from various molybdenum purity levels to achieve the required performance for specialized applications.

-

Coating Treatment: Enhance performance and longevity with tailored coatings, such as anti-oxidation or conductive layers, to suit specific environments.

-

Connection Design: Customize connection methods, such as welded joints or bolted structures, for secure and efficient installation.

-

Packaging: Opt for customized packaging solutions designed for safe transportation and storage, ensuring product integrity upon arrival.

Why choose molybdenum alloy boat from Peakrise Metal?

At Peakrise Metal, we uphold the highest industry standards by integrating advanced techniques, innovative technology, and unmatched expertise. Our unwavering commitment ensures that your specific needs are met with premium molybdenum alloy boat solutions.

Expertise and Experience: With over a decade in the industry, Peakrise Metal combines advanced technology and deep expertise to deliver high-quality molybdenum alloy boats tailored to your precise requirements.

Custom Solutions: We offer personalized solutions, including custom sizes, shapes, and coatings, ensuring our molybdenum alloy boats meet exact specifications and performance demands.

Unmatched Quality: Our commitment to superior manufacturing standards guarantees that each molybdenum alloy boat delivers outstanding performance, durability, and reliability, providing excellent value for your investment

Our workshop

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Our Package

|

|

|

|

|

|

|

|

|

|

Certificate

|

Applications

Molybdenum thermal boats are widely used in:

Vacuum Evaporation & Thin Film Deposition

Utilized to evaporate metals (Al, Ag, Au) and compounds (oxides, nitrides) in vacuum chambers.

Semiconductor Industry

Essential for thin film applications in microelectronics and circuit manufacturing.

Optical Coating

Used in mirror coatings, anti-reflective layers, and display coatings.

Metal Refining & Surface Treatment

Applied in metal purification and surface hardening processes.

Aerospace & Defense

Reliable in extreme temperature environments for specialized coatings and material processing.

|

|

Manufacturing Process

Our molybdenum thermal boats are manufactured using advanced processing techniques to ensure precision and reliability:

Raw Material Selection: High-purity molybdenum and alloyed compositions.

Stamping & Forming: Precision cutting and shaping to meet application-specific designs.

Surface Treatment: Polishing and refining for improved thermal performance.

Quality Inspection: Rigorous testing for dimensional accuracy, purity, and durability.

Quality Assurance

ISO 9001 certified manufacturing process.

Each batch undergoes metallurgical analysis and thermal testing.

Guaranteed high-density, crack-resistant molybdenum material.

We offer:

Technical Consultation: Assistance in selecting the right molybdenum boat for your process.

Custom Manufacturing: Tailored sizes and shapes for specific industrial needs.

After-Sales Support: Quick response to inquiries and troubleshooting assistance.

For inquiries and bulk orders, contact us now!

📧 Email: info@peakrisemetal.com

📲 WhatsApp: +8613186382597

FAQs

Q: What are molybdenum thermal boats used for?

A: They are primarily used in high-temperature processes such as vacuum evaporation, thin film deposition, and semiconductor manufacturing.

Q: Can the size be customized?

A: Yes, we offer customized molybdenum boats based on your specific requirements.

Q: What is the minimum order quantity (MOQ)?

A: Our MOQ is 1 piece, making it convenient for both small and large-scale applications.

Q: What is the delivery time?

A: Standard orders are delivered within 5-7 days, while custom orders may take longer.

Q: What are the available payment terms?

A: We accept T/T payments with negotiable terms for bulk orders.

Order now and experience superior performance with our high-quality molybdenum thermal boats!

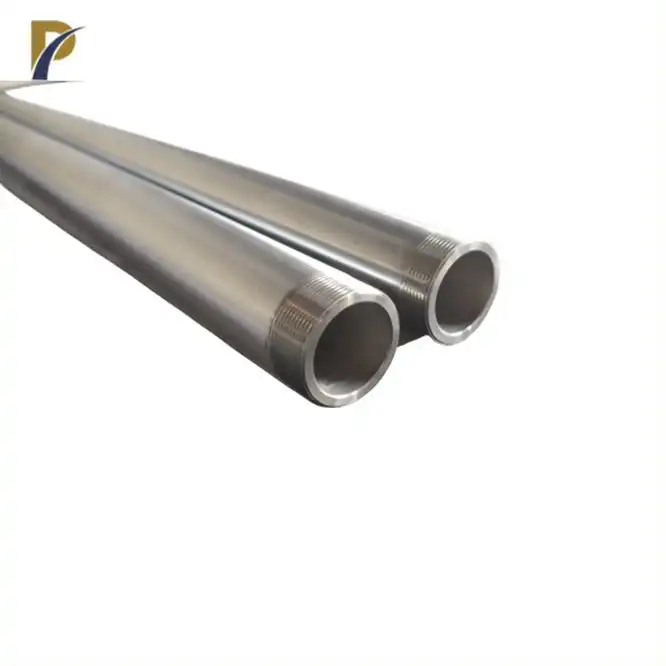

YOU MAY LIKE

-

VIEW MOREmolybdenum electrodes glass melting

VIEW MOREmolybdenum electrodes glass melting -

VIEW MOREmolybdenum evaporation boats

VIEW MOREmolybdenum evaporation boats -

VIEW MOREmolybdenum vacuum boat

VIEW MOREmolybdenum vacuum boat -

VIEW MOREmolybdenum crucible uhv evaporator

VIEW MOREmolybdenum crucible uhv evaporator -

VIEW MOREmolybdenum in x ray tube

VIEW MOREmolybdenum in x ray tube -

VIEW MOREtungsten welding electrodes

VIEW MOREtungsten welding electrodes -

VIEW MOREtungsten heavy alloy

VIEW MOREtungsten heavy alloy -

VIEW MOREhigh temperature furnace tungsten crucible

VIEW MOREhigh temperature furnace tungsten crucible