Selecting the right zirconium sheet thickness is crucial for optimal performance in various applications. The ideal thickness depends on factors such as intended use, mechanical stress, and environmental conditions. For aerospace components, thinner sheets (0.5-2mm) are often preferred for weight reduction. In chemical processing, thicker sheets (3-10mm) provide enhanced corrosion resistance. Nuclear applications typically require medium thicknesses (2-5mm) to balance neutron absorption and structural integrity. Consider your specific requirements and consult with experts to determine the most suitable zirconium sheet thickness for your project.

Understanding Zirconium Sheet Properties

Chemical Composition and Grades

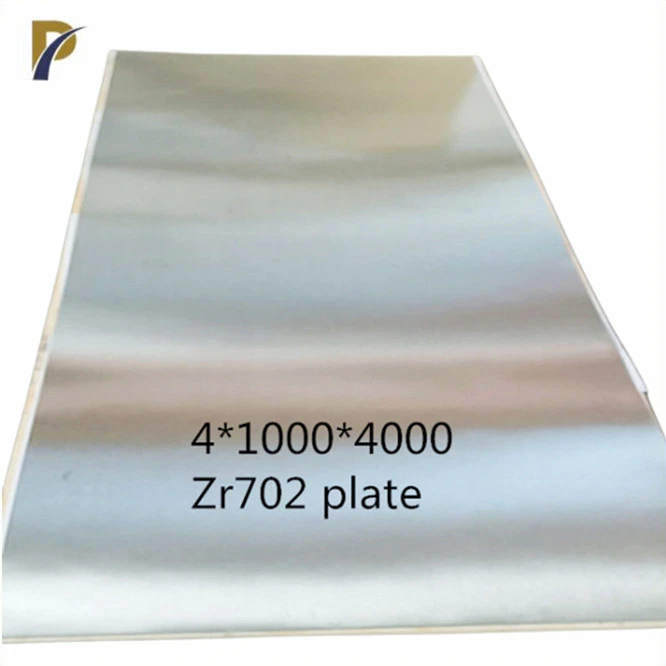

Zirconium sheets are produced in several grades, each featuring a distinct chemical composition optimized for specific industrial applications. The most commonly used grades include Zr702, Zr704, and Zr705. Zr702, with a high purity of over 99.2% zirconium, is highly corrosion-resistant and widely applied in chemical processing equipment. Zr704 and Zr705 incorporate small amounts of alloying elements, which improve mechanical strength, hardness, and overall durability, making these grades suitable for more demanding applications such as nuclear, aerospace, and specialized engineering environments.

Mechanical Characteristics

Zirconium sheets offer outstanding mechanical performance, combining a high strength-to-weight ratio with excellent ductility and formability. Depending on the specific grade and processing, yield strength typically ranges between 200 and 400 MPa. These properties allow zirconium sheets to withstand structural loads while being shaped into complex geometries. Additionally, their remarkable fatigue resistance ensures that components maintain integrity under repeated stress cycles. These characteristics make zirconium sheets particularly suitable for aerospace, nuclear, and other high-performance applications where durability, reliability, and long-term structural stability are essential.

Corrosion Resistance

A key advantage of zirconium sheets is their exceptional resistance to corrosion, particularly in harsh chemical environments. The material can withstand exposure to strong acids, alkalis, and chlorine-containing compounds without significant degradation. This superior corrosion resistance is due to the formation of a stable, self-healing oxide layer on the surface, which protects the underlying metal from further chemical attack. Consequently, zirconium sheets provide long-lasting performance, reduce maintenance costs, and are widely used in chemical processing, marine, and nuclear industries where durability and reliability are critical.

|

|

Factors Influencing Zirconium Sheet Thickness Selection

Application Requirements

The specific application is a primary factor when selecting the appropriate zirconium sheet thickness. Different industrial uses demand varying levels of strength, flexibility, and durability. For example, chemical plant heat exchangers or reaction vessels may require thicker sheets to resist high pressures and exposure to corrosive fluids. In contrast, aerospace components often emphasize weight reduction, requiring thinner sheets while still maintaining sufficient structural integrity. Understanding the operational demands of each application ensures the chosen thickness optimizes performance, reliability, and longevity without compromising safety or functionality.

Environmental Conditions

Environmental factors significantly influence the optimal thickness of zirconium sheets. In high-temperature or high-radiation settings, such as nuclear reactors, thicker sheets may be needed to account for potential material degradation and thermal expansion over time. Similarly, components subjected to mechanical stress, vibration, or abrasive environments benefit from increased thickness to enhance durability and prevent deformation or failure. By carefully considering the operating environment, engineers can select zirconium sheet thicknesses that balance structural resilience, corrosion resistance, and long-term performance under demanding conditions.

Cost Considerations

While zirconium sheets offer exceptional properties for demanding applications, cost is an important consideration when determining thickness. Thicker sheets typically involve higher material and manufacturing costs, making it essential to balance performance requirements with economic feasibility. Selecting a thickness that meets mechanical, thermal, and chemical criteria without over-engineering helps optimize both budget and functionality. Collaborating with material experts ensures that the chosen sheet thickness provides the necessary strength, corrosion resistance, and durability while maintaining cost-effectiveness for industrial applications.

Zirconium Sheet Thickness Recommendations by Industry

Aerospace Industry

In aerospace applications, zirconium sheets are highly valued for their excellent strength-to-weight ratio, corrosion resistance, and ability to withstand extreme conditions. For structural components, typical sheet thicknesses range from 0.5mm to 2mm, providing sufficient mechanical strength while minimizing overall weight, which is critical for flight performance and fuel efficiency. In specialized applications, such as heat shields and thermal protection systems, thicker sheets of up to 5mm may be required to endure high temperatures, thermal cycling, and mechanical stresses, ensuring reliability and safety in demanding aerospace environments.

|

|

Chemical Processing

The chemical processing industry extensively uses zirconium sheets due to their exceptional corrosion resistance and durability in aggressive chemical environments. For reaction vessels, storage tanks, and piping, sheet thicknesses generally range from 3mm to 10mm, depending on vessel size, internal pressure, and exposure to corrosive chemicals. Heat exchanger applications often employ thinner sheets between 0.5mm and 2mm, optimizing heat transfer efficiency while maintaining structural integrity. By carefully selecting thickness based on specific operating conditions, chemical engineers can ensure safe, long-lasting, and cost-effective equipment performance.

Nuclear Energy Sector

Zirconium sheets are indispensable in the nuclear energy sector due to their low neutron absorption, radiation resistance, and excellent mechanical properties. Fuel cladding commonly utilizes thin sheets or tubes with wall thicknesses around 0.6mm to 0.7mm, providing adequate protection for nuclear fuel while minimizing neutron interference. Structural components inside reactors often require thicker sheets ranging from 2mm to 5mm to ensure durability, stability, and long-term performance under high temperatures, radiation exposure, and mechanical stress. Proper thickness selection is crucial to maintaining operational safety and reactor efficiency.

Conclusion

Choosing the right zirconium sheet thickness is a critical decision that impacts performance, durability, and cost-effectiveness across various industries. By carefully considering application requirements, environmental conditions, and industry-specific standards, you can optimize your selection for maximum benefit. Remember that consulting with material experts and suppliers can provide valuable insights tailored to your specific needs, ensuring the best possible outcome for your zirconium sheet application.

FAQs

What is the standard thickness range for zirconium sheets?

Zirconium sheets are typically available in thicknesses ranging from 0.3mm to 50mm.

How does thickness affect the corrosion resistance of zirconium sheets?

While zirconium's corrosion resistance is primarily due to its surface oxide layer, thicker sheets can provide additional protection in extremely corrosive environments.

Can zirconium sheets be custom-ordered to specific thicknesses?

Yes, many manufacturers offer custom thickness options to meet specific application requirements.

High-Quality Zirconium Sheets in Various Thicknesses | Peakrise Metal

At Shaanxi Peakrise Metal Co., Ltd., we specialize in providing high-quality zirconium sheets tailored to your specific needs. As a leading zirconium sheet manufacturer and supplier, we offer a wide range of thicknesses and grades to suit diverse applications. Our state-of-the-art production facilities and rigorous quality control ensure consistent excellence in every sheet we produce. For expert guidance on selecting the ideal zirconium sheet thickness for your project, contact our team at info@peakrisemetal.com.

References

Smith, J.R. (2021). "Zirconium in Aerospace: Material Selection and Applications."

Johnson, L.M. (2020). "Corrosion Resistance of Zirconium Alloys in Chemical Processing Industries."

Anderson, K.L. (2022). "Nuclear-Grade Zirconium: Properties and Performance in Reactor Environments."

Chen, Y. (2019). "Mechanical Behavior of Zirconium Sheets Under Various Loading Conditions."

Williams, R.T. (2021). "Cost-Effective Design with Zirconium Alloys in Industrial Applications."

Brown, S.A. (2020). "Zirconium Sheet Thickness Optimization: A Case Study in Heat Exchanger Design."