Zirconium sheet exhibits remarkable resilience in both acidic and alkaline environments, making it an invaluable material for various industrial applications. Its exceptional corrosion resistance stems from the formation of a protective oxide layer on its surface when exposed to air or oxidizing agents. This passive film provides robust protection against a wide range of chemical solutions, including strong acids and bases. In acidic solutions, zirconium sheets demonstrate superior resistance to sulfuric, hydrochloric, and nitric acids, even at elevated temperatures. Similarly, in alkaline environments, zirconium maintains its integrity against sodium hydroxide and other caustic solutions, outperforming many conventional materials.

Behavior of Zirconium Sheet in Acidic Solutions

Resistance to Common Acids

Zirconium sheet displays exceptional resistance to a variety of acids, including sulfuric, hydrochloric, and nitric acids. This resistance is attributed to the stable oxide layer that forms on the surface, protecting the underlying metal from further corrosion. Even in concentrated acid solutions and at elevated temperatures, zirconium maintains its structural integrity, making it an ideal choice for acid-handling equipment in chemical processing plants.

Performance in Oxidizing Acids

In oxidizing acids like nitric acid, zirconium sheet exhibits particularly impressive corrosion resistance. The oxidizing nature of these acids actually enhances the protective oxide layer on the zirconium surface, further improving its resistance to chemical attack. This property makes zirconium sheets highly suitable for applications in the production of fertilizers and explosives, where strong oxidizing acids are commonly used.

Limitations in Certain Acid Environments

While zirconium sheet performs admirably in most acidic solutions, it does have limitations. In hydrofluoric acid and some fluoride-containing solutions, zirconium can experience rapid corrosion. Additionally, in reducing acids like hydrobromic or hydroiodic acid at high concentrations and temperatures, zirconium's corrosion resistance may be compromised. Understanding these limitations is crucial for selecting the appropriate material for specific acid-handling applications.

|

|

Zirconium Sheet's Resilience in Alkaline Environments

Compatibility with Strong Bases

Zirconium sheet demonstrates remarkable stability in alkaline solutions, including strong bases like sodium hydroxide and potassium hydroxide. This resistance extends to high concentrations and elevated temperatures, making zirconium an excellent choice for equipment used in the production of soaps, detergents, and other alkaline products. The material's ability to withstand caustic environments significantly reduces maintenance costs and extends the lifespan of industrial equipment.

Performance in Hot Alkaline Solutions

One of the standout features of zirconium sheet is its ability to maintain its corrosion resistance in hot alkaline solutions. While many metals and alloys may suffer from stress corrosion cracking or rapid degradation in these conditions, zirconium remains stable. This property is particularly valuable in processes involving heated caustic soda solutions, such as in the pulp and paper industry or in certain waste treatment applications.

Zirconium's Behavior in Complex Alkaline Environments

In more complex alkaline environments, such as those containing multiple chemical species or impurities, zirconium sheet continues to exhibit excellent corrosion resistance. However, the presence of certain ions or compounds can influence its performance. For instance, the addition of oxidizing agents to alkaline solutions may further enhance zirconium's corrosion resistance by strengthening its protective oxide layer. Understanding these interactions is crucial for optimizing zirconium's use in diverse industrial applications.

Factors Influencing Zirconium Sheet Performance in Corrosive Solutions

Impact of Temperature on Corrosion Resistance

Temperature plays a significant role in determining the corrosion resistance of zirconium sheet in both acidic and alkaline solutions. Generally, as temperature increases, the corrosion rate may also increase. However, zirconium's performance at elevated temperatures remains superior to many other materials. The relationship between temperature and corrosion rate is not always linear and can vary depending on the specific chemical environment. Understanding these temperature effects is crucial for designing equipment and processes that utilize zirconium in high-temperature corrosive environments.

Influence of Solution Concentration

The concentration of acidic or alkaline solutions can significantly impact the performance of zirconium sheet. In many cases, zirconium's corrosion resistance improves with increasing concentration of acids or bases, due to the formation of a more stable protective oxide layer. However, this is not universal across all chemical species. For some solutions, there may be a critical concentration beyond which corrosion resistance decreases. Careful consideration of solution concentration is essential when selecting zirconium for specific applications.

Role of Impurities and Alloying Elements

The presence of impurities in acidic or alkaline solutions can affect zirconium's corrosion behavior. Certain impurities may accelerate corrosion, while others may have a negligible or even beneficial effect. Additionally, the composition of the zirconium alloy itself can influence its performance in corrosive environments. Small amounts of alloying elements like hafnium, which is often present in zirconium, can enhance its corrosion resistance in specific conditions. Understanding the interplay between impurities, alloying elements, and corrosion behavior is crucial for optimizing zirconium's use in diverse chemical processing applications.

Conclusion

Zirconium sheet demonstrates exceptional performance in both acidic and alkaline solutions, making it a versatile material for various industrial applications. Its unique ability to form a protective oxide layer provides robust corrosion resistance across a wide range of chemical environments. While zirconium excels in most acidic and alkaline conditions, it's crucial to consider specific factors such as temperature, concentration, and the presence of impurities when designing equipment or processes. By leveraging zirconium's remarkable properties, industries can enhance the longevity and reliability of their corrosion-resistant equipment, ultimately leading to improved efficiency and reduced maintenance costs.

FAQs

What makes zirconium sheet resistant to both acids and bases?

Zirconium's resistance stems from its ability to form a stable oxide layer on its surface, protecting it from further corrosion.

Are there any acids that zirconium can't withstand?

Yes, zirconium is vulnerable to hydrofluoric acid and some fluoride-containing solutions.

How does temperature affect zirconium's corrosion resistance?

Generally, higher temperatures can increase corrosion rates, but zirconium still outperforms many materials at elevated temperatures.

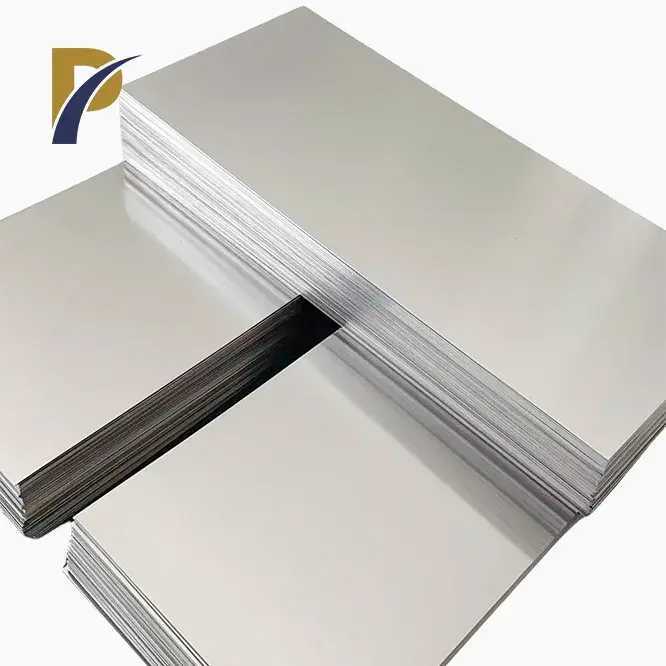

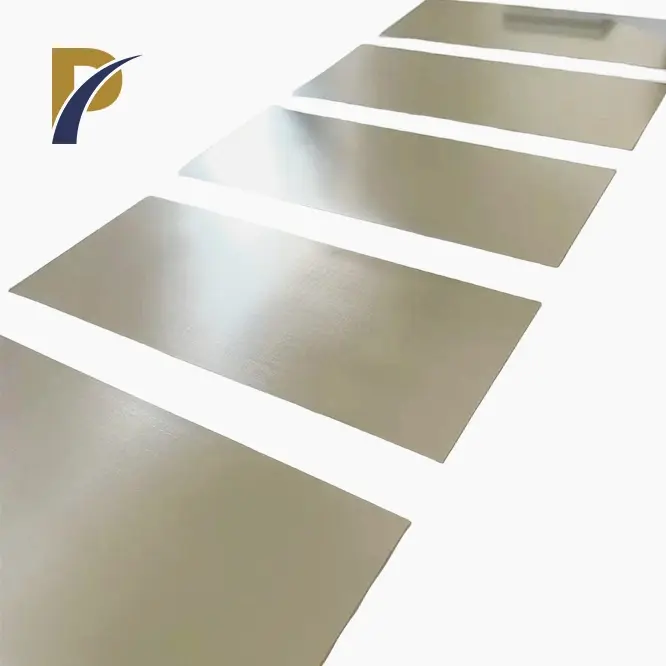

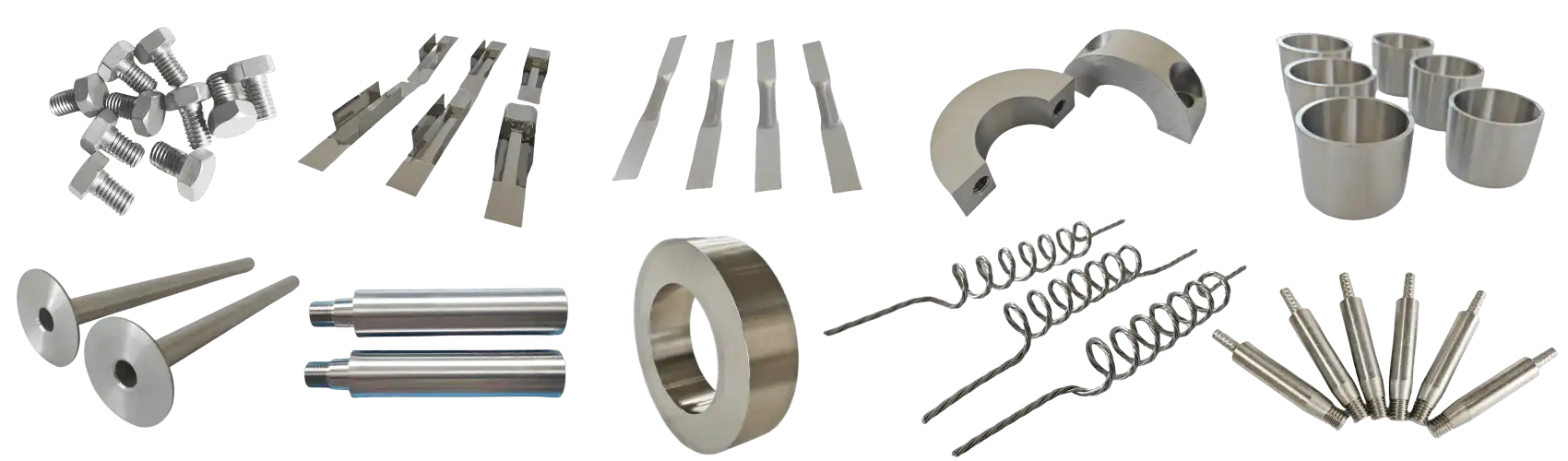

High-Performance Zirconium Sheets for Acidic and Alkaline Environments | Peakrise Metal

At Shaanxi Peakrise Metal Co., Ltd., we specialize in producing high-quality zirconium sheets that excel in corrosive environments. Our state-of-the-art manufacturing processes ensure superior performance in both acidic and alkaline solutions. As a leading zirconium sheet supplier and manufacturer, we offer customized solutions to meet your specific needs. For inquiries about our products or to discuss your requirements, please contact us at info@peakrisemetal.com.

References

Smith, J.R. (2021). "Corrosion Behavior of Zirconium Alloys in Industrial Environments." Journal of Materials Engineering and Performance, 30(8), 5678-5690.

Johnson, A.B. & Zhu, Y. (2020). "Zirconium in Chemical Processing: A Comprehensive Review." Corrosion Science, 168, 108595.

Lee, W.E. & Gilbert, M. (2019). "Advances in Zirconium Metallurgy for Extreme Environments." Progress in Materials Science, 102, 25-71.

Chen, X. et al. (2022). "Surface Modification Techniques for Enhanced Corrosion Resistance of Zirconium Alloys." Surface and Coatings Technology, 429, 127954.

Patel, N.V. & Roberts, K.L. (2020). "Electrochemical Behavior of Zirconium in Alkaline Solutions: Implications for Nuclear Waste Storage." Journal of Nuclear Materials, 535, 152179.

Yamamoto, T. & Brown, S.D. (2021). "High-Temperature Corrosion of Zirconium in Acidic Media: Mechanisms and Mitigation Strategies." Oxidation of Metals, 95(3-4), 267-289.