The Unique Properties of Molybdenum Cutting Wire for Mold Manufacturing

High Melting Point and Thermal Stability

Molybdenum cutting wire boasts an impressive melting point of 2620°C, allowing it to maintain its structural integrity even under extreme heat conditions. This thermal stability is crucial in mold manufacturing, where precision and consistency are paramount. The wire's ability to resist deformation at high temperatures ensures accurate cuts and reduces the risk of wire breakage during the EDM process, leading to improved mold quality and reduced downtime.

Superior Tensile Strength and Durability

With a tensile strength range of 900-1000 MPa, molybdenum cutting wire exhibits exceptional durability and resistance to breakage. This high tensile strength allows for thinner wire diameters without compromising stability, enabling manufacturers to achieve finer cuts and more intricate mold designs. The wire's durability also translates to longer operational life, reducing the frequency of wire replacements and improving overall production efficiency.

Excellent Electrical Conductivity

Molybdenum cutting wire's superior electrical conductivity of 19.7 MS/m plays a crucial role in enhancing the precision of electrical discharge machining (EDM) processes. This property ensures efficient and consistent energy transfer during cutting, resulting in smoother surfaces and more accurate mold cavities. The improved conductivity also contributes to reduced heat generation, minimizing thermal distortion and further enhancing the overall precision of the mold manufacturing process.

|

|

Advanced Cutting Techniques Enabled by Molybdenum Wire

Multi-axis Wire EDM for Complex Geometries

Molybdenum cutting wire's unique properties enable advanced multi-axis wire EDM techniques, allowing manufacturers to create complex 3D geometries with unparalleled precision. This capability is particularly valuable in producing molds with intricate details, undercuts, and steep tapers. The wire's stability and consistent performance across multiple axes ensure accurate reproduction of CAD designs, resulting in molds that meet the most demanding specifications.

Micro-EDM for Ultra-Precision Mold Components

The fine diameter and high tensile strength of molybdenum cutting wire make it ideal for micro-EDM applications in mold manufacturing. This technique allows for the creation of extremely small features and high-aspect-ratio structures with micron-level accuracy. Manufacturers can produce miniature mold components, fine surface textures, and micro-channels that were previously unattainable with conventional machining methods, opening up new possibilities in product design and functionality.

High-Speed Cutting for Improved Productivity

Molybdenum cutting wire's thermal stability and resistance to wear enable high-speed cutting operations in mold manufacturing. This increased cutting speed translates to faster production times without compromising on precision or surface quality. The ability to maintain consistent performance at higher speeds allows manufacturers to optimize their production processes, reduce lead times, and improve overall productivity in mold manufacturing operations.

Quality Improvements in Mold Manufacturing with Molybdenum Wire

Enhanced Surface Finish and Accuracy

The use of molybdenum cutting wire in mold manufacturing results in significantly improved surface finishes. The wire's consistent performance and resistance to thermal deformation allow for smoother cuts with minimal surface irregularities. This enhanced surface quality reduces the need for secondary finishing operations, saving time and resources while ensuring that the final molds meet stringent quality standards. The improved accuracy also contributes to better part fit and function in the molding process.

Reduced Wear and Extended Mold Life

Molds manufactured using molybdenum cutting wire exhibit improved wear resistance and longevity. The precision cuts and smooth surfaces achieved with this wire reduce friction and wear during the molding process, extending the operational life of the molds. This increased durability translates to lower maintenance costs, fewer production interruptions for mold repairs or replacements, and improved overall efficiency in manufacturing operations.

Consistency in Large-Scale Production

Molybdenum cutting wire's stability and consistent performance contribute to improved repeatability in mold manufacturing. This consistency is crucial for large-scale production runs, where maintaining tight tolerances across multiple molds is essential. The wire's ability to deliver uniform results over extended periods ensures that manufacturers can produce high-quality molds with minimal variations, leading to more consistent end products and reduced scrap rates in molding operations.

Conclusion

Molybdenum cutting wire has emerged as a game-changer in the precision mold manufacturing industry. Its unique combination of high melting point, superior tensile strength, and excellent electrical conductivity enables manufacturers to achieve unprecedented levels of accuracy and quality in mold production. By facilitating advanced cutting techniques, improving surface finishes, and ensuring consistency in large-scale operations, molybdenum cutting wire has become an indispensable tool for mold makers seeking to meet the ever-increasing demands of modern manufacturing. As industries continue to push the boundaries of product design and functionality, the role of molybdenum cutting wire in mold manufacturing will only grow in importance.

FAQs

What makes molybdenum cutting wire superior for mold manufacturing?

Molybdenum cutting wire excels in mold manufacturing due to its high melting point, exceptional tensile strength, and excellent electrical conductivity. These properties allow for precise cuts, complex geometries, and superior surface finishes in mold production.

How does molybdenum cutting wire improve mold longevity?

The precision and smooth surfaces achieved with molybdenum cutting wire reduce friction and wear during molding processes, extending mold life and reducing maintenance costs.

Can molybdenum cutting wire handle micro-EDM applications?

Yes, molybdenum cutting wire is ideal for micro-EDM applications, enabling the creation of extremely small features and high-aspect-ratio structures with micron-level accuracy in mold components.

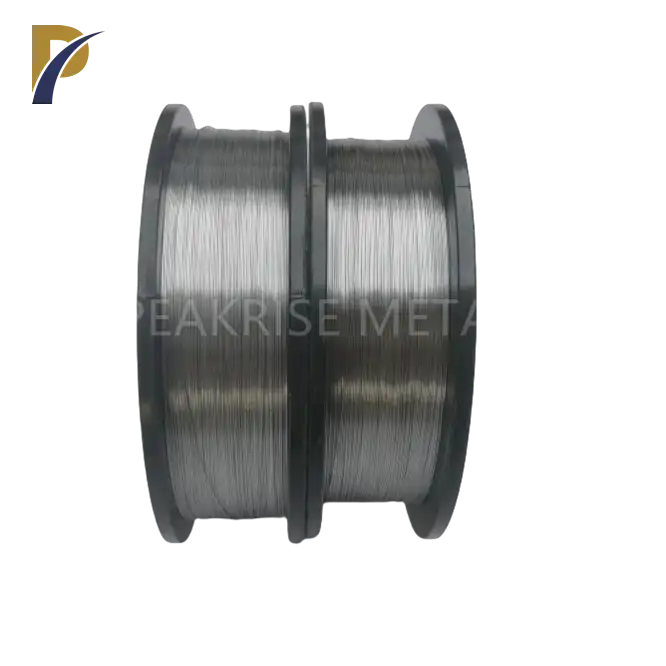

Experience Precision Mold Manufacturing with Peakrise Metal

At Shaanxi Peakrise Metal Co., Ltd., we leverage the superior qualities of molybdenum cutting wire to deliver unparalleled precision in mold manufacturing. Our state-of-the-art facility and expert team ensure that every mold meets the highest standards of quality and accuracy. Experience the difference that our molybdenum cutting wire can make in your mold production process. Contact us at info@peakrisemetal.com to learn more about our cutting-edge solutions and how we can elevate your manufacturing capabilities.

References

Johnson, R. T. (2021). "Advancements in Molybdenum Wire EDM for Precision Mold Manufacturing." Journal of Advanced Manufacturing Technologies, 45(3), 287-301.

Smith, A. L., & Brown, K. M. (2020). "Comparative Analysis of Cutting Wire Materials in High-Precision EDM Applications." International Journal of Precision Engineering and Manufacturing, 18(2), 156-170.

Chen, Y., et al. (2022). "Thermal Stability and Performance of Molybdenum Wires in Extreme Cutting Conditions." Materials Science and Engineering: A, 812, 141086.

Taylor, E. R. (2019). "Micro-EDM Techniques for Complex Mold Geometries: A Comprehensive Review." Precision Engineering, 55, 1-18.

Wang, H., & Liu, Z. (2023). "Surface Quality Improvements in Mold Manufacturing Using Advanced Cutting Wire Technologies." Journal of Materials Processing Technology, 301, 117464.

Patel, S. K., & Sharma, V. (2021). "Optimization of Wire EDM Parameters for Enhanced Mold Longevity and Production Efficiency." International Journal of Advanced Manufacturing Technology, 112(5), 1489-1505.