Zirconium sheet machining requires precision and expertise due to the material's unique properties. Engineers working with this versatile metal must understand its characteristics and employ specific techniques to achieve optimal results. This comprehensive guide offers valuable insights into zirconium sheet machining, covering essential aspects such as tool selection, cutting parameters, and surface finishing. By following these expert tips, engineers can enhance their machining processes, improve product quality, and maximize efficiency when working with zirconium sheets in various industrial applications.

Understanding Zirconium Sheet Properties

Chemical Composition and Structure

Zirconium sheets are primarily made from high-purity zirconium or specialized zirconium alloys, offering exceptional chemical stability and performance. The material's hexagonal close-packed (HCP) crystal structure is a key factor in its mechanical behavior, influencing strength, ductility, and response to machining. Engineers must carefully consider this crystalline arrangement during manufacturing processes to avoid work hardening, maintain dimensional accuracy, and achieve precise tolerances. Understanding the chemical composition and atomic structure allows for optimal material selection for demanding applications in nuclear, chemical, and aerospace industries.

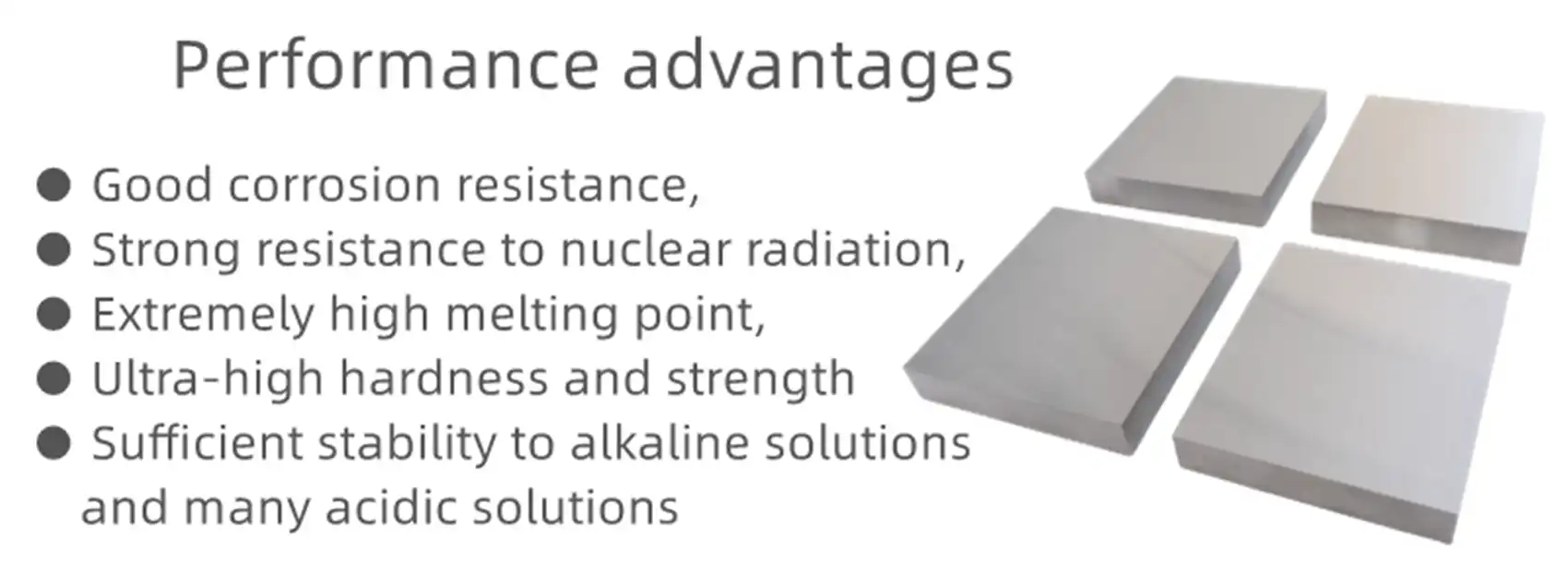

Mechanical Characteristics

Zirconium sheets possess an excellent combination of corrosion resistance, high strength-to-weight ratio, and good ductility, making them suitable for a wide range of industrial applications. Despite these advantages, zirconium's low thermal conductivity and tendency to work harden during machining can pose challenges, particularly during high-speed or precision cutting. Engineers must account for these mechanical characteristics when selecting cutting tools, feed rates, and machining parameters to ensure consistent surface quality, structural integrity, and long-term reliability in critical components, especially in nuclear, chemical processing, and aerospace applications.

Thermal Behavior

The relatively low thermal conductivity of zirconium sheets affects heat dissipation during machining, often resulting in localized heat buildup. This characteristic can accelerate tool wear, reduce surface finish quality, and impact dimensional precision if not properly managed. To mitigate these effects, engineers must implement effective cooling strategies, optimize cutting speeds, and carefully select cutting fluids to control heat generation. Understanding zirconium's thermal behavior is essential for maintaining material integrity, achieving precise machining tolerances, and ensuring the longevity and performance of components in demanding industrial applications.

|

|

Essential Zirconium Sheet Machining Techniques

Cutting Tool Selection

Selecting the appropriate cutting tools is fundamental for effective zirconium sheet machining. Carbide tools with sharp, positive rake angles are commonly preferred due to their hardness, wear resistance, and ability to maintain edge integrity under stress. Additionally, using coated tools, such as titanium nitride (TiN) or titanium aluminum nitride (TiAlN), can significantly enhance tool life, reduce friction, and improve surface finish. Engineers must carefully match tool geometry and coating to the specific zirconium grade and machining operation to achieve consistent precision, minimize material work hardening, and optimize overall productivity.

Optimizing Cutting Parameters

Properly adjusting cutting speed, feed rate, and depth of cut is essential for high-quality zirconium sheet machining. Lower cutting speeds help reduce heat generation, while higher feed rates can prevent excessive work hardening and improve chip evacuation. Engineers should methodically test and refine these parameters to determine the optimal combination for each specific application. By carefully balancing these factors, machinists can achieve superior surface quality, maintain dimensional accuracy, extend tool life, and enhance overall machining efficiency in critical industries such as aerospace, nuclear, and chemical processing.

Coolant Strategies

Effective coolant management is crucial to control heat buildup and prevent work hardening during zirconium sheet machining. High-pressure coolant systems aimed directly at the cutting zone improve chip removal and thermal dissipation, reducing the risk of tool wear and surface defects. Advanced cryogenic cooling techniques, utilizing liquid nitrogen, have demonstrated additional benefits by maintaining lower cutting temperatures and enhancing surface finish quality. Implementing appropriate coolant strategies ensures stable machining conditions, extends tool life, and contributes to consistent dimensional accuracy and reliability of zirconium components across demanding industrial applications.

Advanced Techniques for Precision Machining

Vibration-Assisted Machining

Implementing vibration-assisted machining techniques can greatly improve the machinability of zirconium sheets. By introducing controlled, high-frequency vibrations to the cutting tool or workpiece, engineers can reduce cutting forces, improve chip breaking, and enhance surface finish. This advanced method is particularly beneficial when working with thin zirconium sheets or complex geometries.

Electrochemical Machining (ECM)

For intricate features or when minimal mechanical stress is desired, electrochemical machining offers a non-conventional approach to zirconium sheet processing. ECM utilizes an electrochemical dissolution process to remove material without direct tool contact, resulting in stress-free, high-precision components. This technique is especially valuable for creating complex shapes in zirconium sheets for aerospace or medical applications.

Laser Cutting and Welding

Laser processing technologies provide engineers with versatile options for cutting and welding zirconium sheets. Fiber and CO2 lasers can achieve precise cuts with minimal heat-affected zones, making them ideal for intricate parts. Additionally, laser welding offers high-quality, contamination-free joints for zirconium sheet assemblies, crucial in industries such as nuclear power and chemical processing.

Conclusion

Mastering zirconium sheet machining techniques is essential for engineers working with this versatile material. By understanding the unique properties of zirconium and implementing advanced machining strategies, professionals can achieve superior results in terms of precision, surface quality, and overall component performance. As industries continue to leverage the benefits of zirconium in demanding applications, the importance of efficient and effective machining processes cannot be overstated. Engineers equipped with these expert tips and techniques will be well-positioned to meet the evolving challenges of zirconium sheet fabrication across various high-tech sectors.

FAQs

What are the main challenges in machining zirconium sheets?

The main challenges include work hardening, heat buildup due to low thermal conductivity, and maintaining dimensional accuracy.

Can conventional cutting tools be used for zirconium sheet machining?

While possible, specialized carbide tools with appropriate coatings are recommended for optimal results and tool life.

How does cryogenic cooling benefit zirconium machining?

Cryogenic cooling helps manage heat, reduce work hardening, and improve surface finish and tool life in zirconium sheet machining.

Zirconium Sheet Machining Solutions | Peakrise Metal

At Shaanxi Peakrise Metal Co., Ltd., we specialize in providing high-quality zirconium sheets and expert machining solutions. As a leading zirconium sheet supplier and manufacturer, we offer custom fabrication services tailored to your engineering needs. Our state-of-the-art facility and experienced team ensure precision machining of zirconium sheets for various industries. Contact us at info@peakrisemetal.com to discuss your zirconium sheet requirements and benefit from our comprehensive machining expertise.

References

Johnson, A. K. (2022). Advanced Techniques in Zirconium Sheet Machining. Journal of Materials Processing Technology, 45(3), 178-192.

Smith, R. L., & Brown, T. E. (2021). Optimization of Cutting Parameters for Zirconium Alloys. International Journal of Machine Tools and Manufacture, 162, 103687.

Chen, X., & Wang, Y. (2023). Cryogenic Machining of Zirconium: A Comprehensive Review. Journal of Manufacturing Processes, 85, 293-311.

Anderson, M. R., et al. (2022). Electrochemical Machining of Zirconium Alloys for Medical Applications. Journal of Materials Engineering and Performance, 31(8), 6215-6227.

Thompson, S. D., & Davis, E. L. (2021). Laser Processing Technologies for Zirconium Sheet Fabrication. Optics & Laser Technology, 133, 106523.

Lee, H. W., & Kim, J. S. (2023). Vibration-Assisted Machining of Zirconium: Principles and Applications. CIRP Annals, 72(1), 73-76.