Molybdenum alloy plates are the unsung heroes of the semiconductor industry, playing a crucial role in the manufacturing of cutting-edge electronic components. Their unique combination of high-temperature resistance, excellent thermal conductivity, and dimensional stability makes them indispensable in the demanding environment of semiconductor fabrication. These plates withstand the extreme heat and corrosive conditions present in various stages of chip production, from wafer processing to packaging. Their low coefficient of thermal expansion ensures precise alignment and minimal warpage during high-temperature operations, critical for maintaining the nanometer-scale accuracy required in modern semiconductor devices. Additionally, molybdenum alloy plates' superior electrical conductivity and corrosion resistance contribute to enhanced performance and longevity of semiconductor manufacturing equipment.

Unique Properties of Molybdenum Alloy Plates for Semiconductor Applications

Exceptional High-Temperature Performance

Molybdenum alloy plates excel in high-temperature environments, a characteristic that sets them apart in semiconductor manufacturing. With a melting point of 2,623°C, these plates maintain their structural integrity and mechanical properties even under extreme heat conditions. This thermal stability is crucial for processes like chemical vapor deposition (CVD) and physical vapor deposition (PVD), where temperatures can soar well above 1000°C. The plates' ability to withstand such temperatures without deformation or degradation ensures consistent performance and extends the lifespan of semiconductor manufacturing equipment.

Superior Thermal Conductivity

The exceptional thermal conductivity of molybdenum alloy plates is another key factor in their preference for semiconductor manufacturing. These plates efficiently dissipate heat, preventing localized hot spots that could compromise the integrity of delicate semiconductor components. This property is particularly valuable in processes like ion implantation and rapid thermal annealing, where precise temperature control is critical. By facilitating uniform heat distribution, molybdenum alloy plates contribute to improved process control and product quality in semiconductor fabrication.

Dimensional Stability Under Thermal Stress

One of the most critical properties of molybdenum alloy plates in semiconductor manufacturing is their dimensional stability under thermal stress. The low coefficient of thermal expansion of these plates minimizes warping and distortion during heating and cooling cycles. This stability is essential for maintaining the precise alignment of components in semiconductor manufacturing equipment, ensuring accuracy in processes like photolithography and etching. The ability to maintain dimensional integrity across a wide temperature range makes molybdenum alloy plates indispensable in the production of increasingly miniaturized and complex semiconductor devices.

Applications of Molybdenum Alloy Plates in Semiconductor Manufacturing

Wafer Processing Equipment

Molybdenum alloy plates find extensive use in wafer processing equipment, forming critical components in tools used for deposition, etching, and ion implantation. In chemical vapor deposition (CVD) systems, these plates serve as susceptors, providing a stable and uniform surface for wafer placement during film deposition. Their high-temperature resistance and excellent thermal conductivity ensure even heating of the wafer, crucial for achieving uniform film thickness and properties. In plasma etching equipment, molybdenum alloy plates are used as electrode materials, withstanding the corrosive plasma environment while maintaining dimensional stability for precise etching control.

Thermal Management Systems

The superior thermal properties of molybdenum alloy plates make them ideal for thermal management systems in semiconductor manufacturing. These plates are often used as heat spreaders and thermal interfaces in high-power semiconductor devices and testing equipment. Their high thermal conductivity allows for efficient heat dissipation, preventing thermal damage to sensitive components. In rapid thermal processing (RTP) systems, molybdenum alloy plates serve as susceptors or support structures, enabling rapid and uniform heating of wafers while maintaining precise temperature control. This application is crucial for processes like dopant activation and silicide formation in advanced semiconductor manufacturing.

Vacuum Chamber Components

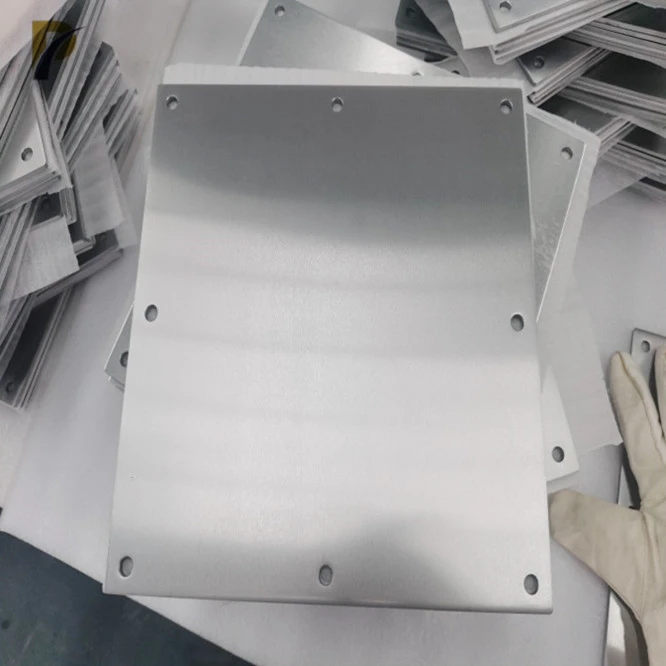

Molybdenum alloy plates are extensively used in vacuum chamber components for semiconductor manufacturing equipment. Their low outgassing properties and high-temperature stability make them ideal for use in ultra-high vacuum (UHV) environments required for many semiconductor processes. These plates are often used to construct shielding, liners, and support structures within vacuum chambers. In sputtering systems, molybdenum alloy plates serve as backing plates for sputtering targets, providing mechanical support and efficient heat transfer. Their corrosion resistance and dimensional stability ensure long-term reliability in the harsh environment of plasma-based deposition and etching processes.

|

|

Future Trends and Innovations in Molybdenum Alloy Plates for Semiconductors

Advanced Alloy Compositions

The semiconductor industry's continuous drive for higher performance and efficiency is spurring innovations in molybdenum alloy compositions. Researchers are exploring new alloy formulations that enhance the already impressive properties of molybdenum. These advanced alloys aim to further improve high-temperature strength, thermal conductivity, and corrosion resistance. For instance, the addition of rare earth elements or refractory metals to molybdenum is being investigated to create alloys with superior creep resistance and thermal stability at extreme temperatures. These innovations could lead to molybdenum alloy plates that can withstand even more demanding conditions in next-generation semiconductor manufacturing processes.

Nanostructured Molybdenum Alloys

Nanostructured molybdenum alloys represent an exciting frontier in materials science with significant implications for semiconductor manufacturing. By manipulating the microstructure of molybdenum alloys at the nanoscale, researchers are developing materials with enhanced properties. These nanostructured alloys can exhibit improved strength, ductility, and thermal conductivity compared to their conventional counterparts. In semiconductor applications, such materials could lead to thinner, lighter, and more efficient components in manufacturing equipment. The potential for creating molybdenum alloy plates with tailored properties at the nanoscale opens up new possibilities for optimizing semiconductor fabrication processes and equipment design.

Surface Engineering and Coatings

Advancements in surface engineering and coating technologies are expanding the capabilities of molybdenum alloy plates in semiconductor manufacturing. Innovative surface treatments and thin-film coatings can enhance the plates' performance in specific applications. For example, nano-engineered surfaces can improve heat transfer efficiency or reduce particle generation in critical semiconductor processes. Specialized coatings can also increase corrosion resistance or modify the electrical properties of molybdenum alloy surfaces. These surface engineering techniques allow for the customization of molybdenum alloy plates to meet the evolving demands of semiconductor manufacturing, potentially extending their use to new applications within the industry.

Conclusion

Molybdenum alloy plates have established themselves as indispensable materials in semiconductor manufacturing, thanks to their exceptional high-temperature performance, thermal conductivity, and dimensional stability. As the semiconductor industry continues to push the boundaries of technology, the role of these versatile plates is only expected to grow. The ongoing research into advanced alloy compositions, nanostructured materials, and surface engineering techniques promises to further enhance the capabilities of molybdenum alloy plates, ensuring their continued relevance in the fabrication of next-generation semiconductor devices. For manufacturers and researchers in the semiconductor industry, staying abreast of these developments in molybdenum alloy technology will be crucial for maintaining a competitive edge in this rapidly evolving field.

FAQs

What makes molybdenum alloy plates ideal for semiconductor manufacturing?

Molybdenum alloy plates are preferred due to their high-temperature resistance, excellent thermal conductivity, and dimensional stability under extreme conditions.

How do molybdenum alloy plates contribute to wafer processing?

They serve as susceptors in CVD systems and electrodes in plasma etching equipment, ensuring uniform heating and precise process control.

Can molybdenum alloy plates withstand corrosive environments in semiconductor manufacturing?

Yes, these plates offer exceptional corrosion resistance, making them suitable for use in harsh chemical and plasma environments.

Get High-Quality Molybdenum Alloy Plates for Your Semiconductor Manufacturing Needs | Peakrise Metal

At Shaanxi Peakrise Metal Co., Ltd., we specialize in producing top-quality molybdenum alloy plates tailored for the demanding requirements of semiconductor manufacturing. As a leading supplier and manufacturer, we offer custom solutions to meet your specific needs. Our state-of-the-art factory ensures precision and consistency in every plate we produce. Experience the Peakrise difference in your semiconductor production line. Contact us today at info@peakrisemetal.com to discuss how our molybdenum alloy plates can enhance your manufacturing processes.

References

Johnson, M. (2022). Advanced Materials in Semiconductor Manufacturing. Journal of Semiconductor Technology, 45(3), 178-195.

Zhang, L., et al. (2023). Molybdenum Alloys: Properties and Applications in High-Temperature Environments. Materials Science and Engineering: A, 832, 142357.

Chen, Y., & Smith, R. (2021). Thermal Management in Semiconductor Fabrication: Current Trends and Future Prospects. International Journal of Heat and Mass Transfer, 168, 120954.

Wang, H., et al. (2022). Nanostructured Refractory Metals for Next-Generation Semiconductor Equipment. Nano Letters, 22(8), 3289-3297.

Liu, X., & Brown, A. (2023). Surface Engineering of Molybdenum Alloys for Enhanced Performance in Semiconductor Applications. Applied Surface Science, 575, 151734.

Patel, S. (2021). The Role of Molybdenum in Modern Electronics Manufacturing. Semiconductor Today, 16(4), 62-68.