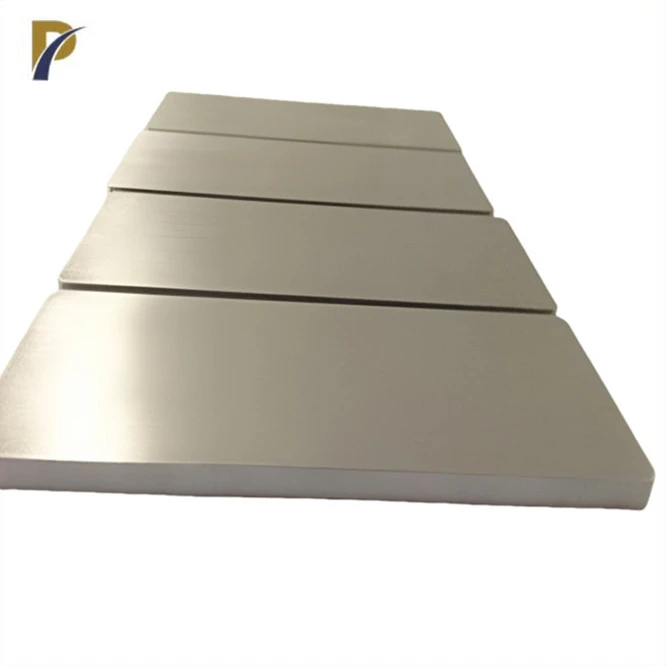

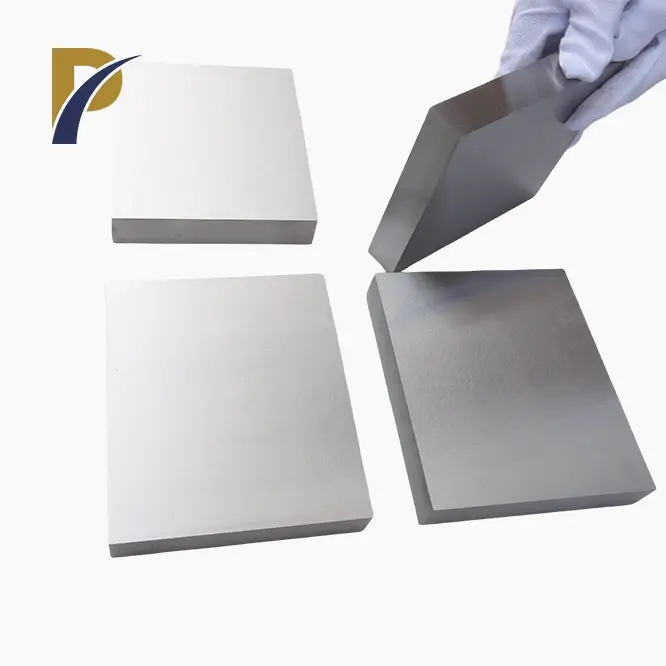

Selecting the appropriate thickness for molybdenum alloy plates is crucial for ensuring optimal performance in various industrial applications. The ideal thickness depends on factors such as the intended use, operating temperature, mechanical stress, and desired lifespan of the component. To make an informed decision, consider the specific requirements of your project, including thermal conductivity, corrosion resistance, and structural integrity. Consulting with experts at Shaanxi Peakrise Metal Co., Ltd. can provide valuable insights into choosing the right thickness for your molybdenum alloy plates, ensuring maximum efficiency and longevity in your industrial processes.

Factors Influencing Molybdenum Alloy Plate Thickness Selection

Application-Specific Requirements

Different industries and applications have unique demands for molybdenum alloy plates. In aerospace, thinner plates may be preferred for weight reduction, while in high-temperature furnaces, thicker plates might be necessary for improved thermal stability. Consider the specific needs of your application, such as heat resistance, electrical conductivity, or structural support, when determining the ideal thickness.

Thermal Considerations

Molybdenum alloy plates are renowned for their exceptional heat resistance. The thickness of the plate directly impacts its thermal properties. Thicker plates generally offer better heat distribution and can withstand higher temperatures for extended periods. However, in applications where rapid heat transfer is crucial, thinner plates might be more suitable. Assess the operating temperature range and thermal cycling requirements of your application to choose the optimal thickness.

Mechanical Stress and Load-Bearing Capacity

The thickness of molybdenum alloy plates plays a significant role in their ability to withstand mechanical stress and bear loads. Thicker plates offer greater structural integrity and are better suited for applications involving high pressure or heavy loads. Conversely, thinner plates may suffice for applications with lower mechanical demands. Evaluate the expected stress levels and load requirements to determine the appropriate thickness that ensures both performance and safety.

|

|

Optimizing Performance Through Precise Thickness Selection

Balancing Weight and Strength

Finding the right balance between weight and strength is crucial when selecting the thickness of molybdenum alloy plates. In industries where weight is a critical factor, such as aerospace or portable electronics, thinner plates can provide the necessary strength while minimizing overall weight. However, in applications where structural integrity is paramount, such as high-pressure vessels or load-bearing components, thicker plates may be essential to ensure safety and longevity.

Corrosion Resistance and Longevity

Molybdenum alloy plates are prized for their excellent corrosion resistance. The thickness of the plate can influence its ability to withstand corrosive environments over time. Thicker plates generally offer enhanced corrosion resistance due to the increased material volume. However, in some cases, thinner plates with specialized surface treatments may provide adequate protection. Consider the corrosive agents present in your application and the expected lifespan of the component when choosing the optimal thickness.

Cost-Effectiveness and Material Efficiency

While it may be tempting to opt for thicker plates for added durability, it's essential to consider cost-effectiveness and material efficiency. Thicker plates require more raw material and may increase overall project costs. Carefully assess whether the additional thickness provides tangible benefits for your specific application. In some cases, innovative designs or alternative molybdenum alloy compositions may allow for thinner plates without compromising performance, resulting in more efficient material usage and cost savings.

| Element | Composition % | ||

| Grade | |||

| 361(Mo-1) | 364(TZM) | 366(Mo-30%W) | |

| C | 0.01 max. | 0.01~0.04 | 0.03 max. |

| O,max. | 0.007 | 0.03 | 0.0025 |

| N,max. | 0.002 | 0.002 | 0.002 |

| Fe, max. | 0.01 | 0.01 | 0.01 |

| Ni, max. | 0.005 | 0.005 | 0.005 |

| Si, max. | 0.01 | 0.005 | 0.01 |

| Ti | 0.4~0.55 | ||

| W | 27~33 | ||

| Zr | 0.06~0.12 | ||

| Mo | Remain | Remain | Remain |

Expert Guidance for Molybdenum Alloy Plate Thickness Selection

Consultation with Industry Specialists

Choosing the right thickness for molybdenum alloy plates can be complex, given the multitude of factors involved. Consulting with industry specialists, such as the experts at Shaanxi Peakrise Metal Co., Ltd., can provide invaluable insights. These professionals have extensive experience in molybdenum alloy applications across various industries and can offer tailored recommendations based on your specific requirements. Their expertise can help you navigate the intricacies of material properties, manufacturing processes, and industry standards to ensure optimal thickness selection.

Customized Solutions for Unique Applications

In some cases, standard thickness options may not fully meet the requirements of specialized applications. Leading molybdenum alloy plate manufacturers offer customized solutions to address unique challenges. By working closely with these manufacturers, you can explore the possibility of custom thickness options or even gradient thickness plates that provide varying properties across different sections. This tailored approach ensures that you get the exact specifications needed for your project, optimizing performance and efficiency.

Leveraging Advanced Testing and Simulation

Modern technology allows for advanced testing and simulation of molybdenum alloy plates under various conditions. Utilizing these tools can provide valuable data on how different thicknesses perform in specific applications. Finite element analysis (FEA) and thermal simulations can help predict the behavior of plates under different stresses and temperatures. By leveraging these advanced techniques, you can make more informed decisions about the optimal thickness for your molybdenum alloy plates, potentially saving time and resources in the long run.

Conclusion

Selecting the right thickness for molybdenum alloy plates is a critical decision that impacts the performance, longevity, and cost-effectiveness of your industrial applications. By carefully considering factors such as application requirements, thermal properties, mechanical stress, and corrosion resistance, you can make an informed choice. Consulting with experts and leveraging advanced testing methods can further refine your selection process. Remember that the optimal thickness may vary depending on your specific needs, and customized solutions are often available for unique applications.

FAQs

What is the standard thickness range for molybdenum alloy plates?

Molybdenum alloy plates typically range from 0.1mm to 50mm in thickness, with custom options available for specific applications.

How does thickness affect the heat resistance of molybdenum alloy plates?

Generally, thicker plates offer better heat distribution and can withstand higher temperatures for longer periods, but the optimal thickness depends on the specific thermal requirements of your application.

Can I request custom thickness options for my project?

Yes, many manufacturers, including Shaanxi Peakrise Metal Co., Ltd., offer customized thickness options to meet unique project requirements.

Choose Peakrise Metal for Your Molybdenum Alloy Plate Needs

At Shaanxi Peakrise Metal Co., Ltd., we specialize in providing high-quality molybdenum alloy plates tailored to your specific needs. As a leading manufacturer and supplier, we offer expert guidance in selecting the optimal thickness for your applications. Our state-of-the-art production facilities and rigorous quality control ensure that you receive top-notch products that meet international standards. For personalized assistance and to explore our range of molybdenum alloy plates, contact our team at info@peakrisemetal.com.

References

Johnson, A. (2022). Molybdenum Alloys in High-Temperature Applications: A Comprehensive Guide.

Smith, R. & Lee, K. (2021). Optimizing Thickness Selection for Refractory Metal Plates in Industrial Settings.

Technical Handbook of Molybdenum and Molybdenum Alloys. (2020). International Molybdenum Association.

Zhang, L. et al. (2023). Advanced Simulation Techniques for Predicting Molybdenum Alloy Performance.

Brown, T. (2022). Cost-Effective Strategies in Molybdenum Alloy Plate Manufacturing.

Corrosion Resistance of Molybdenum Alloys: Thickness Considerations. (2021). Journal of Materials Engineering and Performance.