Durable Zirconium Crucibles for Labs

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Durable Zirconium Crucibles for Labs - Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

Zirconium crucibles are essential tools in the laboratory for high-temperature applications, especially where chemical stability and durability are required. As a reactive metal, zirconium has excellent corrosion resistance, high melting points, and the ability to withstand extreme thermal and chemical environments. These properties make zirconium crucibles indispensable in advanced laboratory settings, particularly for research in metallurgy, materials science, and analytical chemistry.

Shaanxi Peakrise Metal Co., Ltd., a leading manufacturer and supplier of non-ferrous metals, provides high-quality Durable Zirconium Crucibles for Labs. With our expertise in producing and processing refractory metals like tungsten, molybdenum, tantalum, and zirconium, we have developed zirconium crucibles that meet international standards for performance, purity, and durability. Our products are recognized for their superior heat resistance and corrosion resistance, making them ideal for use in academic, industrial, and research labs worldwide. Whether you require standard or custom sizes, Shaanxi Peakrise Metal Co., Ltd. is your trusted partner for durable, precision-engineered zirconium crucibles.

Product Specifications

| Name: | ICP-OES Laboratory Purification Zirconium Crucible Zr702 Zr Crucible |

| Material: | Zirconium & Zirconium alloy |

| Grade: | Zr702,Zr705,RO60001,RO60901 |

| Density: | 6.51g/cm3 |

| Shape: | Crucible |

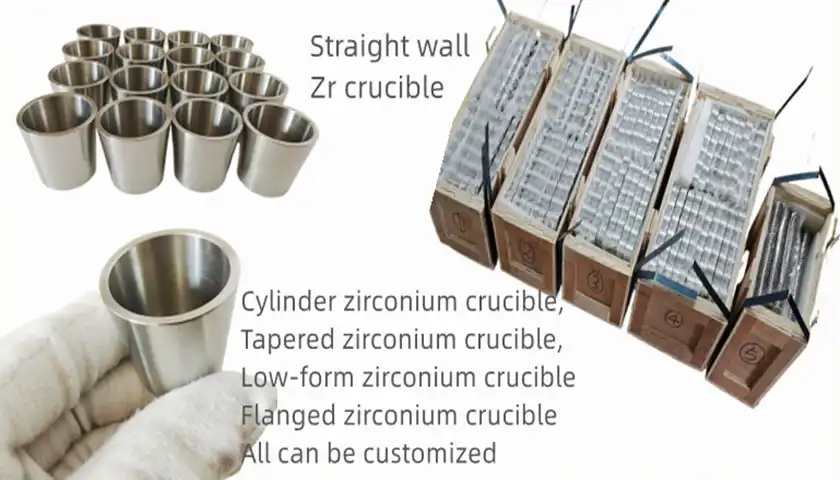

| Type: | Low form zirconiu crucible, flanged rims zirconium crucible,straight wall zirconium crucible, tapered zirconium crucible, Cylindrical zirconium crucible |

| Volume: | 5ml,10ml,15ml,20ml,25ml,30ml,35ml,40ml,45ml,50ml etc, |

| Custom | Yes, process as per customer's drawing. |

Chemical and Physical Properties

| Zr 702 | Zr 704 | Zr 705 | Zircaloy-2 | Zircaloy-4 | |

| Sn | / | 1~2% | 1~2% | 1.2~1.7% | 1.2~1.7% |

| Fe | <0> | 0.1~0.2% | <0> | 0.07~0.2% | 0.07~0.2% |

| Cr | <0> | 0.1~0.2% | <0> | 0.05~0.15% | 0.05~0.15% |

| Ni | / | / | / | 0.03~0.08% | <0> |

| Hf | 1~2.5% | <4> | <4> | ||

| Nb | / | / | 2~3% | ||

| Zn+Hf | ~99.5% | ~97.5% | ~95.5% | ~98% | ~98% |

Product Features

-

High Temperature Resistance

Zirconium crucibles can withstand extreme temperatures of up to 1100°C, making them ideal for applications requiring intense heat, such as metal melting, chemical reactions, and thermal testing. -

Corrosion Resistance

The exceptional resistance of zirconium to alkalis and acids ensures long-lasting performance in harsh chemical environments, reducing the need for frequent replacements. -

Non-reactivity

Zirconium is chemically stable and does not easily react with most substances, making it perfect for maintaining the integrity of experiments that involve volatile chemicals or high-purity materials. -

Durability

Our zirconium crucibles are designed for longevity, offering excellent strength and resistance to wear even under repeated use in aggressive thermal cycles. -

Lightweight and Strong

Despite its strength, zirconium is relatively lightweight, making it easier to handle in lab environments without compromising its durability.

Applications of Zirconium Crucibles

Zirconium crucibles are used in a variety of advanced laboratory applications, including:

-

High-Temperature Metal Melting

Due to their ability to endure high temperatures, zirconium crucibles are widely used for melting metals and other high-temperature applications, such as alloy production and material testing. -

Analytical Chemistry

Zirconium crucibles provide an inert environment, ideal for experiments involving volatile substances, high-purity elements, and sensitive chemical reactions, ensuring accurate results without contamination. -

Metallurgical Research

In the field of metallurgy, these crucibles are utilized to study the behavior of metals at high temperatures, in addition to refining and smelting operations. -

Materials Science

Researchers and scientists rely on zirconium crucibles to analyze the properties of advanced materials, including ceramics, glass, and polymers under extreme conditions.

|

|

Manufacturing Process

|

|

|

Why Choose Shaanxi Peakrise Metal Co., Ltd?

-

Rich Experience

With over a decade of experience in the non-ferrous metals industry, we have established a strong reputation for delivering high-quality materials, including zirconium crucibles, to clients worldwide. -

Global Reach

Our products are exported to countries like the United States, Germany, South Korea, and Australia. We have built long-term relationships with global clients by consistently meeting their high standards. -

Cutting-Edge Technology

We use the latest production techniques, including vacuum arc melting and plasma welding, to produce zirconium crucibles that are both durable and of the highest quality. -

Comprehensive Services

From raw material sourcing to custom fabrication, we offer end-to-end solutions, including OEM and ODM services, to meet the unique needs of our clients. -

Strict Quality Control

Each product is meticulously tested to ensure it meets international quality standards for purity, durability, and performance.

OEM/ODM Services

The Common Size of Zirconium Crucible

| Low form Zirconium crucible | |||||

| Top diameter(mm) | Bottom diameter (mm) | Height (mm) | Wall thickness (mm) | Capacity (ml) | |

| 22 | 18 | 20 | 2 | 3.6ml | |

| 26 | 16 | 20 | 2 | 5.0ml*2mm | |

| 30 | 24 | 26 | 2 | 10ml*2mm | |

| 40 | 26 | 41 | 1 | 30ml*1mm | |

| 42 | 27 | 42 | 2 | 30ml*2mm | |

| 42 | 30 | 42 | 1.6 | 35ml*1.6mm | |

| 41 | 33 | 42 | 2 | 35ml*2mm | |

| 43 | 34 | 40 | 1 | 40ml*1mm | |

| 47 | 40 | 35 | 1 | 45ml*1mm | |

| 49 | 42 | 36 | 2 | 45ml*2mm | |

| 48 | 38 | 45 | 3 | 45ml*3mm | |

| 47 | 40 | 38.5 | 1 | 50ml*1mm | |

| 48 | 40 | 42 | 2 | 50ml*2mm | |

| 56 | 44 | 50 | 2 | 80ml*2mm | |

| AutoFluxer crucible with flanged | |||||

| 48 | 29 | 33 | 2 | 25ml*2mm | |

| 60 | 36 | 39 | 1 | 50ml*1mm | |

| 60 | 36 | 43 | 2 | 50ml*2mm | |

At Shaanxi Peakrise Metal Co., Ltd., we offer flexible OEM/ODM services to meet the specific needs of your laboratory or industrial application. Whether you need a custom size or shape, we work closely with our clients to provide tailored solutions. Our team is capable of producing crucibles in various configurations while maintaining strict quality controls to ensure the final product meets your exact requirements.

FAQ

-

What is the maximum operating temperature of zirconium crucibles?

Zirconium crucibles can operate at temperatures up to 1100°C. -

Can zirconium crucibles be customized?

Yes, we offer custom shapes and sizes based on your specific requirements. -

Are these crucibles resistant to acids and alkalis?

Yes, zirconium has excellent corrosion resistance, making it highly durable in both acidic and alkaline environments. -

How do you ensure product quality?

Each crucible undergoes rigorous inspection and testing, including dimensional checks, material purity tests, and performance evaluations, to ensure they meet industry standards. -

What are the typical applications for zirconium crucibles?

Zirconium crucibles are used in high-temperature metal melting, chemical processing, metallurgical research, and materials science.

Packaging and Logistics

-

Packaging

-

Logistics

- Sea Freight: Ideal for large orders.

- Air Freight: Faster shipping for urgent orders.

- Land Freight: Available for specific destinations.

- Express Delivery: For smaller, time-sensitive shipments.

Contact Us

At Shaanxi Peakrise Metal Co., Ltd., we are committed to providing high-quality zirconium crucibles and exceptional customer service. Whether you are looking to purchase standard crucibles or require customized solutions, we are here to meet your needs.

Contact us today at info@peakrisemetal.com and let’s discuss how we can support your laboratory's success!