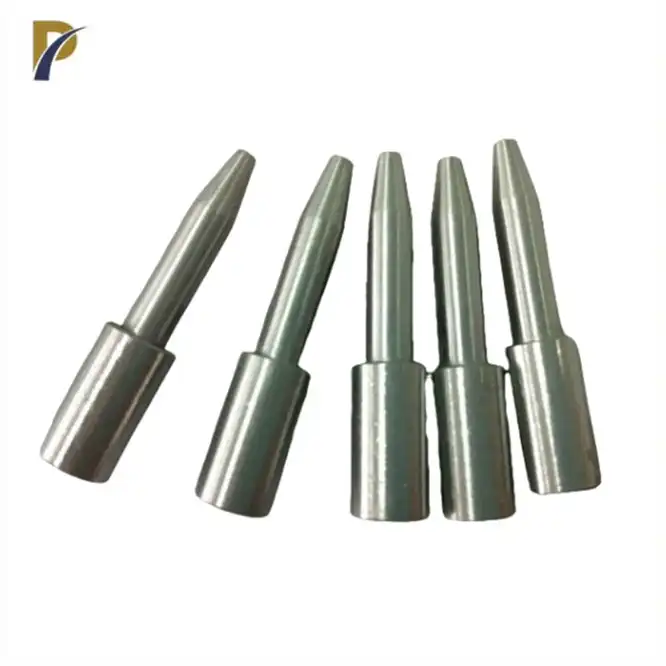

molybdenum tungsten electrodes

Purity: 99.97%

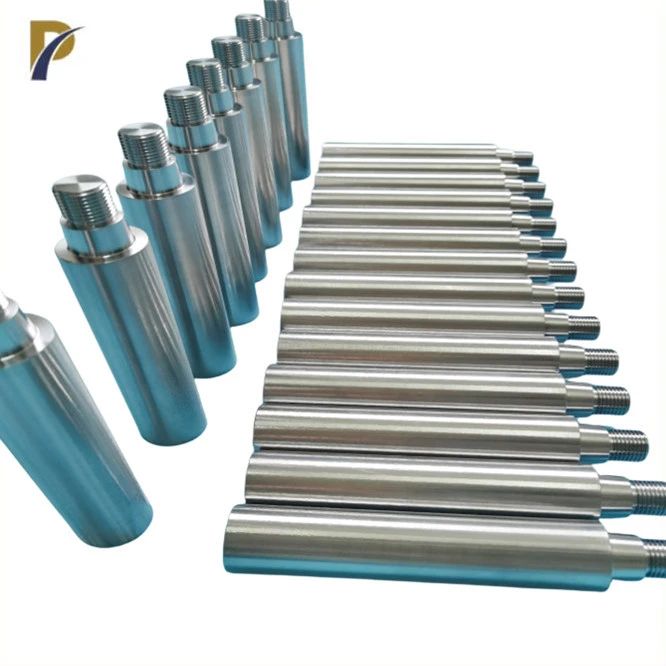

Diameter: 4~120mm

Length: 200~2000mm

Surface: Polished

Standard: ASTM B387

Tensile Strength:≥900MPa

Tensile Strength:≥900MPa

Elongation: ≥15%

Application:Daily glass, optical glass, thermal insulation materials, glass fiber, rare earth industry and other fields

PRODUCT DESCRIPTION

Here is the product introduction page for molybdenum tungsten electrodes for Shaanxi Peakrise Metal Co., Ltd:

Product Introduction

Molybdenum tungsten electrodes are critical components in various high-temperature industrial applications. These electrodes are known for their superior thermal conductivity, high melting points, and resistance to deformation under extreme conditions. Used extensively in industries such as aerospace, electronics, and metal processing, molybdenum tungsten electrodes provide excellent electrical conductivity and durability, ensuring reliability in demanding environments.

As a leading supplier, Shaanxi Peakrise Metal Co., Ltd specializes in producing high-quality molybdenum tungsten electrodes tailored to meet industry needs. With years of experience in the field, we manufacture products designed to excel in challenging conditions, ensuring maximum performance. Our commitment to quality and precision makes us the trusted partner for businesses worldwide.

With the backing of advanced equipment and technology, we have established ourselves as a major player in the global market for non-ferrous metals. Our molybdenum tungsten electrodes are manufactured following strict quality standards, ensuring they meet and exceed customer expectations.

Product Parameters Table

| Parameter | Value | Unit |

|---|---|---|

| Molybdenum Content | 85% | % |

| Tungsten Content | 15% | % |

| Melting Point | 3,620 | °C |

| Thermal Conductivity | 138 | W/mK |

| Density | 10.2 | g/cm³ |

| Electrical Resistivity | 0.0055 | µΩ·m |

| Tensile Strength | 800 | MPa |

| Mechanical Property | Value | Unit |

|---|---|---|

| Fracture Toughness | 12 | MPa·m½ |

| Operating Temperature | 2,000 | °C |

| Heat Capacity | 0.256 | J/gK |

| Oxidation Resistance | Excellent | - |

| Machinability | Moderate | - |

| Wear Resistance | High | - |

| Corrosion Resistance | Superior | - |

|

|

|

Physical and Mechanical Properties

Molybdenum tungsten electrodes offer a unique combination of physical and mechanical properties, making them highly effective in high-stress environments. Key attributes include:

- High Melting Point: The high melting point (3,620°C) ensures that molybdenum tungsten electrodes remain stable and effective even in extreme heat.

- Excellent Thermal Conductivity: The electrodes efficiently dissipate heat, preventing overheating in industrial applications.

- Exceptional Strength: With a tensile strength of 800 MPa, these electrodes withstand mechanical stress without deforming.

- Corrosion and Oxidation Resistance: Their resistance to oxidation and corrosion extends their service life in challenging environments.

- High Density: A density of 10.2 g/cm³ ensures structural integrity and durability, ideal for use in welding and furnace applications.

|

|

Product Functions

- Efficient Heat Dissipation: Molybdenum tungsten electrodes are designed to disperse heat effectively, reducing the risk of overheating in high-temperature processes.

- Enhanced Electrical Conductivity: Their superior electrical conductivity ensures stable performance in welding, cutting, and other industrial applications.

- Durability in Extreme Conditions: The electrodes exhibit outstanding resistance to thermal shock and mechanical stress, ensuring reliable operation in high-stress environments.

- Corrosion Resistance: The combination of molybdenum and tungsten ensures these electrodes resist degradation from exposure to harsh chemicals or extreme conditions.

- Precision Welding: Due to their stable arc and consistent electrical properties, molybdenum tungsten electrodes are widely used for precision welding applications, including in aerospace and electronics.

|

|

|

Product Applications

Molybdenum tungsten electrodes are essential in various industries. Their unique properties make them the ideal choice for high-performance applications:

- Aerospace: Used in propulsion systems, heat shields, and other components that operate under extreme temperatures and pressures.

- Electronics: Applied in the manufacture of semiconductors, circuit boards, and other electronic components due to their conductivity and heat resistance.

- Metal Processing: Essential in the smelting and casting of metals, where high temperatures are involved, offering stability and efficiency in the process.

- Welding and Cutting: These electrodes are crucial for high-precision welding and cutting of hard metals, providing clean, reliable performance.

- Furnaces: Used as heating elements in high-temperature furnaces, molybdenum tungsten electrodes ensure consistent heat distribution and longevity.

|

|

Product Process and Production Flow

- Raw Material Selection: We use only the purest molybdenum and tungsten, ensuring that every electrode meets stringent quality standards.

- Powder Mixing and Pressing: The molybdenum and tungsten powders are precisely mixed and pressed into desired shapes.

- Sintering: The pressed powders undergo high-temperature sintering in a vacuum or controlled atmosphere to achieve full density and uniformity.

- Machining and Finishing: After sintering, the electrodes are machined and polished to exact specifications, ensuring consistency across all products.

- Quality Control: Each electrode undergoes rigorous testing to verify its physical and mechanical properties before shipment.

Our Factory

Shaanxi Peakrise Metal Co., Ltd boasts a state-of-the-art production facility equipped with cutting-edge technology. We have invested in advanced machinery, including vacuum arc melting furnaces, electron beam welding machines, and CNC lathes. This enables us to offer high-quality, precision-engineered products that meet international standards. Our dedicated R&D team continually explores innovative ways to improve product quality and efficiency.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

We provide a range of packaging and logistics options to meet our customers' needs:

-

Packaging:

- Wooden crates

- Carton packaging

- Foam-filled protective packaging

- Waterproof and moisture-proof custom packaging

- International standard packaging

-

Logistics:

- Sea shipping

- Airfreight

- Land transport

- Multimodal transportation

- Express courier services

|

|

|

|

|

|

|

|

Why Choose Us?

- Rich Experience: Over a decade of experience in non-ferrous metal production, ensuring reliable and high-quality products.

- Global Reach: Our products are exported to various countries, including the U.S., Germany, and Australia.

- State-of-the-Art Equipment: Advanced production technology enables us to meet international standards with precision.

- Customization: OEM/ODM services allow for tailored solutions based on customer specifications.

- High-Quality Assurance: ISO9001-certified, we prioritize quality at every stage of production.

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd, we pride ourselves on offering custom processing services. Our OEM and ODM capabilities allow clients to design and order products that meet their exact needs. From material selection to final product testing, we ensure that each custom order meets the highest standards of quality and performance.

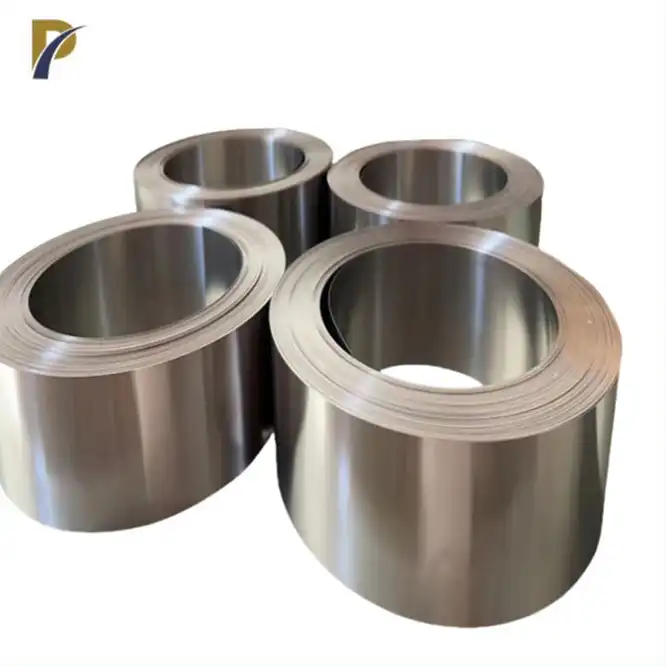

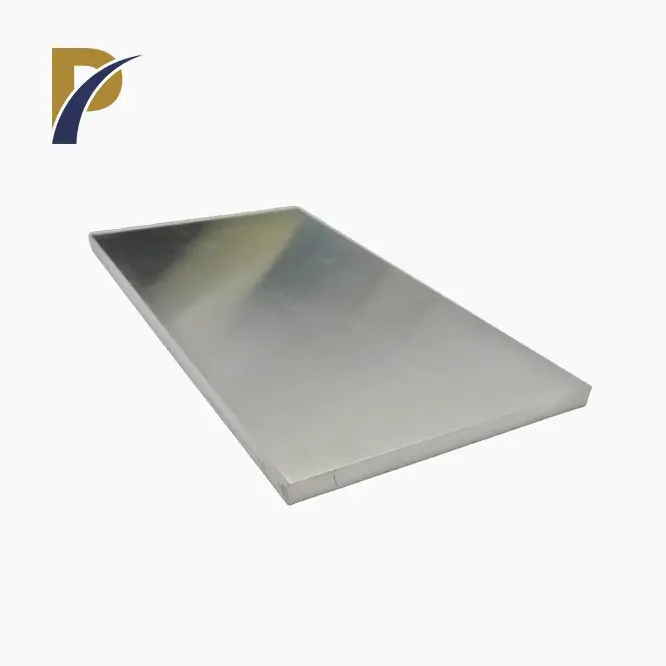

Products Produced By Shaanxi Peakrise Metal Co.,Ltd

|

|

|

|

|

|

|

|

|

FAQ

-

What is the typical delivery time for molybdenum tungsten electrodes?

- We typically deliver orders within 30 days, depending on the quantity and customization needs.

-

Are custom sizes available?

- Yes, we offer customized sizes and specifications to meet your specific project requirements.

-

What are the shipping options?

- We offer various shipping methods, including sea, air, and express courier services.

-

Can you provide samples?

- Yes, we offer samples for evaluation before placing bulk orders.

-

What quality assurance do you provide?

- All products undergo strict quality control, and we are ISO9001-certified, ensuring consistent quality across our product range.

Contact Us

For more information about our molybdenum tungsten electrodes and to discuss your specific needs, please contact us at info@peakrisemetal.com. We welcome inquiries from global purchasers and look forward to establishing long-term partnerships.