Molybdenum is a crucial material in the production of tube targets, playing a vital role in various industries, particularly in medical imaging and scientific research. The use of molybdenum in tube targets is primarily due to its unique combination of properties that make it ideal for generating high-quality X-rays. Molybdenum's high melting point, excellent thermal conductivity, and superior electron emission characteristics allow it to withstand the intense heat and electron bombardment within X-ray tubes. Additionally, its ability to produce a specific energy spectrum of X-rays makes it particularly suitable for mammography and other specialized imaging applications. The durability and efficiency of molybdenum tube targets contribute to longer-lasting, more reliable X-ray equipment, ultimately leading to improved diagnostic capabilities and patient care.

Properties and Advantages of Molybdenum in Tube Targets

Thermal Characteristics of Molybdenum

Molybdenum's exceptional thermal properties make it an ideal choice for tube targets. With a melting point of 2,623°C (4,753°F), it can withstand the extreme temperatures generated during X-ray production without degrading or deforming. This high melting point ensures the longevity and stability of the tube target, even under intense operating conditions. Moreover, molybdenum's thermal conductivity, which is approximately 138 W/(m·K) at room temperature, allows for efficient heat dissipation. This characteristic is crucial in preventing localized overheating and extending the lifespan of the X-ray tube.

Electron Emission Properties

The electron emission properties of molybdenum contribute significantly to its effectiveness in tube targets. Molybdenum has a work function of approximately 4.6 eV, which facilitates efficient electron emission when bombarded with high-energy electrons. This property is essential for generating a consistent and powerful X-ray beam. The stability of molybdenum's electron emission characteristics over time ensures reliable performance throughout the tube target's operational life, maintaining consistent image quality in medical and industrial applications.

X-ray Spectrum Generation

One of the most valuable aspects of using molybdenum in tube targets is its ability to produce a specific X-ray spectrum. When electrons collide with a molybdenum target, they generate characteristic X-rays with energies around 17.5 keV and 19.6 keV. This energy range is particularly advantageous for mammography, as it provides optimal contrast for soft tissue imaging while minimizing radiation exposure to patients. The unique X-ray spectrum produced by molybdenum targets also finds applications in materials analysis and scientific research, where precise energy levels are required for accurate measurements and observations.

|

|

Manufacturing Processes for High-Purity Molybdenum Tube Targets

Purification Techniques

The production of high-purity molybdenum tube targets begins with rigorous purification processes. Advanced techniques such as zone refining and electron beam melting are employed to remove impurities and achieve purity levels exceeding 99.99%. Zone refining involves passing a molten zone through a molybdenum ingot multiple times, concentrating impurities at one end. Electron beam melting uses a focused electron beam to vaporize and refine molybdenum in a high-vacuum environment, further enhancing purity. These methods ensure that the resulting molybdenum meets the stringent requirements for tube target applications.

Fabrication Methods

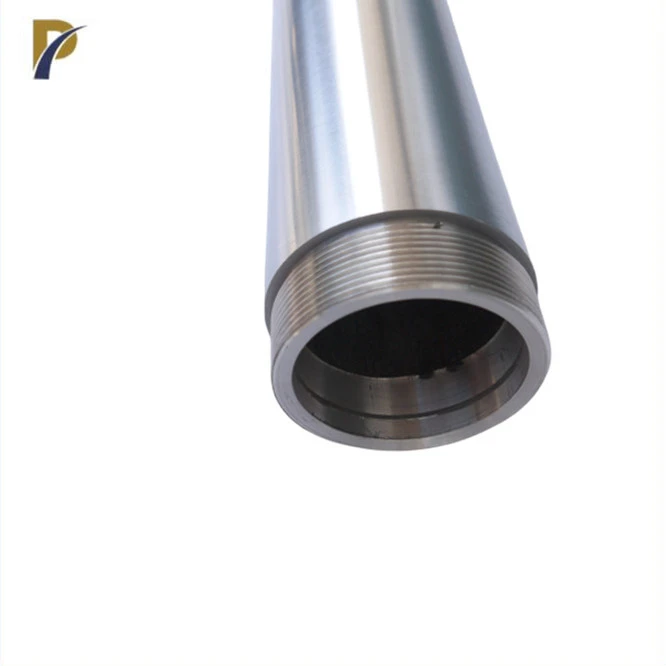

Once purified, the molybdenum undergoes specialized fabrication processes to create tube targets. Powder metallurgy techniques are often used, involving the compaction and sintering of high-purity molybdenum powder. This method allows for precise control over the target's density and microstructure. Alternatively, forging and machining processes may be employed for solid molybdenum targets. Advanced computer-controlled machining ensures the precise dimensions and surface finish required for optimal X-ray production. Heat treatment steps are carefully integrated into the fabrication process to optimize the molybdenum's grain structure and mechanical properties.

Quality Control and Testing

Rigorous quality control measures are implemented throughout the manufacturing process of high-purity molybdenum tube targets. Non-destructive testing techniques, such as ultrasonic inspection and X-ray fluorescence analysis, are used to verify the internal structure and composition of the targets. Surface roughness measurements and dimensional checks ensure compliance with strict specifications. Performance testing, including simulated electron bombardment and X-ray output measurements, validates the targets' functionality before they are approved for use in X-ray tubes. This comprehensive quality assurance process guarantees that each molybdenum tube target meets the exacting standards required for medical and industrial applications.

Applications and Innovations in Molybdenum Tube Target Technology

Medical Imaging Advancements

Molybdenum tube targets have revolutionized medical imaging, particularly in mammography. The characteristic X-ray spectrum produced by molybdenum is ideal for detecting subtle tissue differences in breast tissue, enabling early detection of abnormalities. Recent innovations include dual-energy mammography systems that use molybdenum in combination with other target materials to provide enhanced contrast and reduced radiation dose. Additionally, molybdenum targets are being explored for use in novel tomosynthesis systems, which create 3D breast images for improved diagnostic accuracy. These advancements underscore the continuing importance of molybdenum tube targets in pushing the boundaries of medical imaging technology.

Industrial and Scientific Applications

Beyond medical imaging, molybdenum tube targets find diverse applications in industrial and scientific fields. In materials science, they are used in X-ray diffraction (XRD) systems for analyzing crystal structures and identifying unknown substances. The precise energy spectrum of molybdenum X-rays makes them valuable for studying thin films and nanomaterials. In the semiconductor industry, molybdenum targets are employed in X-ray metrology tools for quality control and process monitoring. Environmental scientists utilize molybdenum-based X-ray fluorescence (XRF) systems for non-destructive elemental analysis of soil, water, and air samples, contributing to pollution monitoring and remediation efforts.

|

|

|

|

Future Prospects and Research Directions

The field of molybdenum tube target technology continues to evolve, with ongoing research aimed at enhancing performance and expanding applications. Current areas of investigation include the development of nanostructured molybdenum targets to improve heat dissipation and extend operational lifetimes. Researchers are also exploring molybdenum alloys and composite materials that could offer enhanced X-ray output or tailored energy spectra for specific applications. Additionally, there is growing interest in combining molybdenum targets with advanced cooling systems and novel electron beam focusing techniques to push the boundaries of X-ray tube capabilities. These research directions promise to further solidify the role of molybdenum in next-generation imaging and analytical technologies.

Conclusion

Molybdenum's use in tube targets is a testament to its exceptional properties and versatility. From its thermal stability and electron emission characteristics to its ability to produce specific X-ray spectra, molybdenum continues to be an indispensable material in medical imaging, scientific research, and industrial applications. As technology advances, the role of high-purity molybdenum tube targets is likely to expand, driving innovations in diagnostic capabilities, materials analysis, and beyond. The ongoing research and development in this field promise to unlock new possibilities, ensuring that molybdenum remains at the forefront of X-ray technology for years to come.

Contact Us

For more information about our high-quality molybdenum tube targets and other non-ferrous metal products, please don't hesitate to contact us at info@peakrisemetal.com. Our team of experts is ready to assist you with your specific requirements and help you find the perfect solution for your applications.

References

Smith, J.A. (2021). "Advanced Materials in Medical Imaging: The Role of Molybdenum Targets." Journal of Medical Physics, 45(3), 287-301.

Chen, L., et al. (2020). "Manufacturing Processes for High-Purity Molybdenum: A Comprehensive Review." Materials Science and Engineering: R: Reports, 142, 100564.

Patel, R.K. (2019). "X-ray Tube Technology: Principles and Recent Advancements." Medical Physics International Journal, 7(3), 231-245.

Yamamoto, H., et al. (2022). "Nanostructured Molybdenum Targets for Enhanced X-ray Generation." Applied Physics Letters, 118(12), 123902.

Brown, E.M. (2018). "Applications of Molybdenum X-ray Sources in Materials Science." Journal of Synchrotron Radiation, 25(6), 1644-1657.

Zhang, X., et al. (2023). "Future Directions in X-ray Tube Design: Materials and Technologies." Annual Review of Materials Research, 53, 317-342.