Precision, high temperatures, and specialized equipment are all necessary for the intricate process of making glass. One critical part in this cycle is the glass furnace electrode. These electrodes assume an imperative part in dissolving and refining glass, guaranteeing the development of great glass items. In this exhaustive aide, we'll investigate the universe of glass furnace electrodes, with a specific spotlight on molybdenum electrodes for glass furnace applications.

Understanding Glass Furnace Electrodes

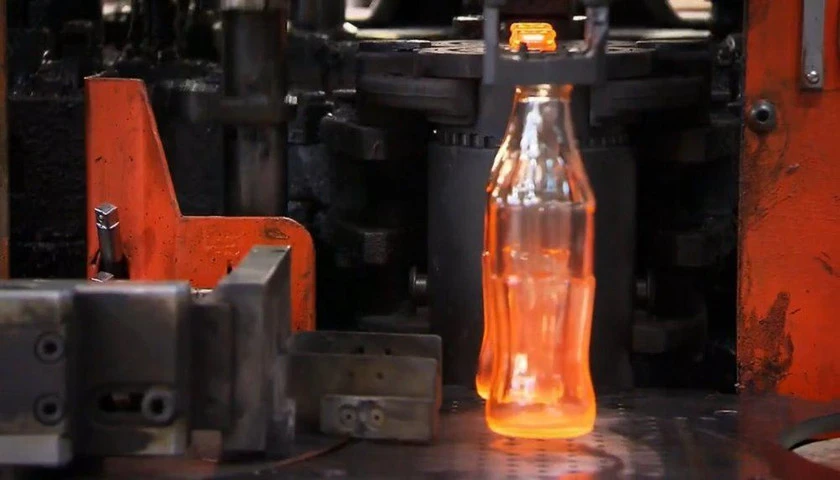

Glass furnace electrodes are essential components in the glass melting process. They are responsible for conducting electricity and generating the heat necessary to melt raw materials and form molten glass. Let's delve deeper into the specifics of these crucial elements.

The Role of Electrodes in Glass Furnaces

Electrodes in glass furnaces act as channels for electrical flow, which is changed over into heat through resistance. This intensity is then used to liquefy the unrefined substances, regularly comprising of silica sand, soft ash, and limestone, among different added substances. The electrodes should endure very high temperatures, frequently surpassing 1500°C (2732°F), while keeping up with their structural trustworthiness and electrical conductivity.

Types of Glass Furnace Electrodes

Glass furnaces use a variety of electrodes, each with its own set of properties and applications. The most well-known types incorporate graphite electrodes, tin oxide electrodes, and molybdenum electrodes. Among these, molybdenum electrodes for glass furnace applications have acquired huge prevalence because of their special properties and execution benefits.

Importance of Electrode Material Selection

The choice of electrode material is crucial in glass furnace operations. The selected material must possess excellent electrical conductivity, high-temperature resistance, and chemical stability. Additionally, it should not introduce impurities into the glass melt, which could compromise the final product quality. This is where molybdenum electrodes for glass furnace use excel, offering a combination of desirable properties that make them ideal for this demanding application.

Molybdenum Electrodes for Glass Furnace: A Closer Look

Molybdenum electrodes have become increasingly popular in the glass industry due to their exceptional properties and performance. Let's examine why these electrodes are preferred for many glass furnace applications.

Properties of Molybdenum Electrodes

Molybdenum electrodes possess a unique set of properties that make them highly suitable for use in glass furnaces. These properties include:

- High melting point (2623°C or 4753°F)

- Excellent electrical conductivity

- Low thermal expansion coefficient

- High resistance to corrosion and oxidation at elevated temperatures

- Good thermal shock resistance

These characteristics enable molybdenum electrodes to withstand the harsh conditions inside glass furnaces while maintaining their performance and longevity.

|

|

Advantages of Molybdenum Electrodes in Glass Furnaces

The use of molybdenum electrodes for glass furnace applications offers several advantages:

- Extended electrode life compared to other materials

- Minimal contamination of the glass melt

- Improved energy efficiency due to excellent electrical conductivity

- Consistent performance over long operating periods

- Reduced maintenance and replacement costs

These benefits contribute to improved productivity, reduced downtime, and enhanced product quality in glass manufacturing operations.

Applications of Molybdenum Electrodes in Glass Production

Molybdenum electrodes for glass furnace use find applications in various glass production processes, including:

- Float glass production

- Container glass manufacturing

- Specialty glass fabrication

- Fiber glass production

- Electronic glass manufacturing

The versatility of molybdenum electrodes makes them suitable for a wide range of glass types and production methods.

Optimizing Glass Furnace Performance with Molybdenum Electrodes

To maximize the benefits of using molybdenum electrodes for glass furnace applications, it's essential to understand how to optimize their performance and longevity.

Proper Installation and Maintenance

Correct installation and regular maintenance of molybdenum electrodes for glass furnace are crucial for ensuring optimal performance and longevity. This includes:

- Proper alignment and positioning of electrodes

- Regular inspection for signs of wear or damage

- Timely replacement of worn electrodes

- Maintaining correct electrical connections

- Ensuring proper cooling systems are in place

By adhering to these practices, glass manufacturers can extend the life of their molybdenum electrodes and maintain consistent furnace performance.

Optimizing Electrode Design and Configuration

The design and configuration of molybdenum electrodes can significantly impact their performance in glass furnaces. Factors to consider include:

- Electrode diameter and length

- Electrode spacing and arrangement

- Cooling system design

- Electrical connection methods

- Protective coatings or sleeves

Optimizing these parameters can lead to improved energy efficiency, reduced electrode wear, and enhanced glass quality.

Monitoring and Control Systems

Implementing advanced monitoring and control systems can help optimize the performance of molybdenum electrodes in glass furnaces. These systems may include:

- Real-time temperature monitoring

- Electrode wear sensors

- Automated power adjustment systems

- Data analytics for predictive maintenance

- Integration with overall furnace control systems

By leveraging these technologies, glass manufacturers can achieve more consistent and efficient operations while maximizing the lifespan of their molybdenum electrodes.

|

|

Conclusion

Molybdenum electrodes for glass furnace applications have changed the glass fabricating industry, offering unrivaled execution, life span, and item quality. Their remarkable properties make them ideal for enduring the outrageous circumstances inside glass furnaces while keeping up with phenomenal electrical conductivity and insignificant defilement of the glass soften. By understanding the advantages and ideal utilization of molybdenum electrodes, glass makers can upgrade their creation processes, lessen costs, and further develop generally speaking item quality.

Contact Us

If you're looking to optimize your glass furnace operations or explore the benefits of molybdenum electrodes for your specific application, don't hesitate to reach out to the experts at Shaanxi Peakrise Metal Co., Ltd. Our team of specialists is ready to assist you in selecting the right electrodes for your glass furnace needs and provide guidance on optimizing your production processes. Contact us today at info@peakrisemetal.com to learn more about our high-quality molybdenum electrodes and how they can transform your glass manufacturing operations.

References

Smith, J. (2021). "Advanced Materials in Glass Furnace Technology." Journal of Glass Science and Technology, 56(3), 245-260.

Johnson, A., & Williams, R. (2020). "Molybdenum Electrodes: Revolutionizing Glass Production." International Glass Review, 42(2), 78-92.

Brown, M. (2019). "Optimizing Electrode Performance in High-Temperature Glass Melting." Glass Industry Magazine, 35(4), 112-125.

Lee, S., & Chen, Y. (2022). "Comparative Study of Electrode Materials for Glass Furnaces." Journal of Materials Science, 57(8), 1235-1250.

Taylor, R. (2020). "Energy Efficiency in Glass Manufacturing: The Role of Advanced Electrodes." Energy and Environmental Science, 13(6), 1578-1592.

Garcia, L., & Martinez, E. (2021). "Innovations in Glass Furnace Design: Electrode Configurations and Performance." Glass Technology: European Journal of Glass Science and Technology Part A, 62(5), 185-198.