In the ever-evolving world of non-ferrous metal manufacturing, molybdenum rhenium electrodes have emerged as a game-changer. These advanced electrodes have revolutionized various industries, from aerospace to electronics, offering unparalleled performance and durability. In this comprehensive exploration, we'll delve into the success stories and valuable lessons learned from the application of molybdenum rhenium electrodes across diverse sectors.

The Rise of Molybdenum Rhenium Electrodes in Industry:

Molybdenum rhenium electrodes have rapidly gained traction in recent years, thanks to their exceptional properties and versatile applications. Let's examine the factors contributing to their widespread adoption and the industries that have benefited most from this innovative technology.

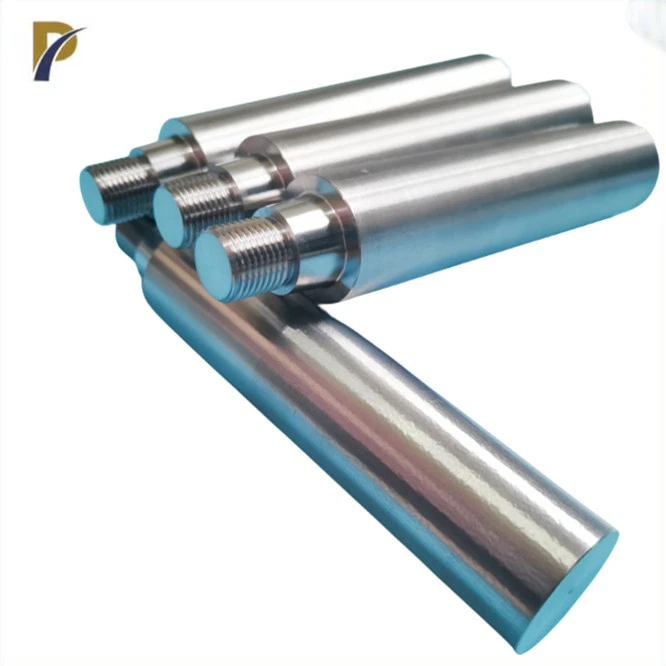

Unprecedented Material Properties:

The special fusion of rhenium and molybdenum results in an electrode material with exceptional properties. These electrodes have outstanding resistance to corrosion and wear, high melting points, and good thermal conductivity. These characteristics make them perfect for applications involving high temperatures and hostile conditions, when conventional electrode materials are inadequate.

Applications Across Industries:

Molybdenum rhenium electrodes have found use in a wide range of industries, including aerospace and semiconductor production. The manufacture of sophisticated alloys and superalloys used in jet engines and spacecraft components is greatly aided by these electrodes in the aerospace sector. They aid in the production of microchips and high-performance semiconductors in the electronics industry.

Driving Innovation and Efficiency

The adoption of molybdenum rhenium electrodes has spurred innovation across industries. Their superior performance has enabled manufacturers to push the boundaries of what's possible, leading to the development of more efficient processes and higher-quality products. This innovation cycle continues to drive demand for these advanced electrodes.

|

|

Success Stories: Molybdenum Rhenium Electrodes in Action

The true measure of any technology lies in its real-world performance. Let's explore some compelling success stories that showcase the transformative power of molybdenum rhenium electrodes across various industries.

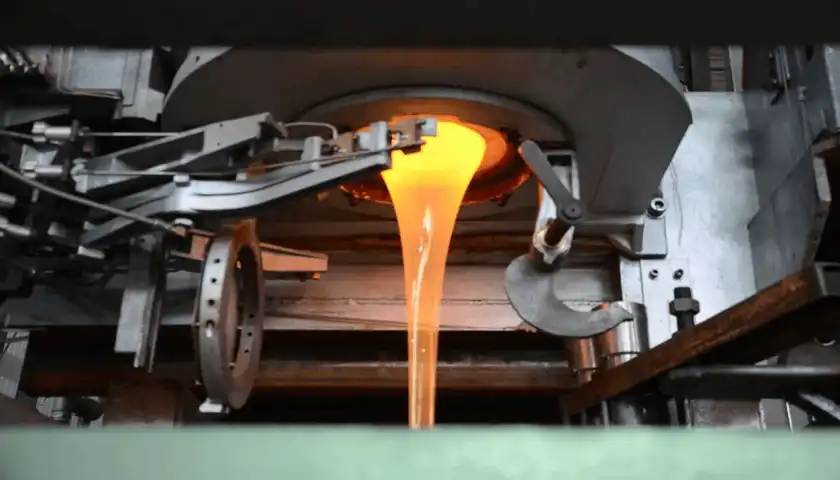

Aerospace Advancements

In the aerospace sector, a leading aircraft engine manufacturer implemented molybdenum rhenium electrodes in their welding processes for turbine components. The result was a significant improvement in weld quality and consistency, leading to enhanced engine performance and reliability. This success story underscores the critical role these electrodes play in advancing aerospace technology.

Semiconductor Breakthroughs

Molybdenum rhenium electrodes were incorporated into the chip manufacturing procedure by a major semiconductor manufacturer. These electrodes' superior heat resistance and conductivity made etching more precise and effective, resulting in microchips that are smaller, faster, and more powerful. The electronics industry as a whole has benefited greatly from this breakthrough.

Energy Sector Innovations

Molybdenum rhenium electrodes were used in the energy industry by a renewable energy company to produce enhanced solar cells. The development of more robust and efficient solar panels was made possible by the electrodes' special qualities, which advanced the field of sustainable energy sources. This success story serves as an example of how these electrodes are advancing important sectors outside of their conventional uses.

|

|

Lessons Learned: Maximizing the Potential of Molybdenum Rhenium Electrodes

While the success stories are impressive, the journey to fully harnessing the power of molybdenum rhenium electrodes has not been without challenges. Let's examine some key lessons learned and best practices for maximizing the potential of these advanced electrodes.

Optimizing Electrode Design

One crucial lesson has been the importance of optimizing electrode design for specific applications. While molybdenum rhenium electrodes offer superior properties, their performance can be further enhanced through careful consideration of factors such as electrode shape, size, and composition. Customizing electrode designs to suit particular processes has led to significant improvements in efficiency and effectiveness.

Mastering Process Parameters

Another valuable lesson has been the need to master process parameters when working with molybdenum rhenium electrodes. Factors such as current density, temperature, and electrode spacing can significantly impact performance. Companies that have invested in understanding and fine-tuning these parameters have reaped the greatest benefits from their use of molybdenum rhenium electrodes.

Continuous Research and Development

The need for constant research and improvement has been maybe the most significant lesson. Molybdenum rhenium electrode technology is still developing, with new advancements and uses being found on a regular basis. Businesses who have shown a commitment to ongoing research and development have remained at the forefront of this technology and have constantly discovered new ways to use these cutting-edge electrodes to gain a competitive edge.

Conclusion

To sum up, molybdenum rhenium electrodes have shown to be a game-changing technology in a number of different industries. These sophisticated electrodes have made major breakthroughs and developments possible in fields like electronics and aircraft. Businesses can fully utilize the potential of molybdenum rhenium electrodes to propel advancement and efficiency in their respective areas by taking lessons from both successes and setbacks. It is obvious that the significance of molybdenum rhenium electrodes will only increase as we continue to push the envelope of what is feasible with them. Keep up with the newest advancements in this industry, whether you're wanting to enhance your present operations or discover new uses for these sophisticated electrodes.

Contact Us

For more information about molybdenum rhenium electrodes and how they can benefit your specific applications, don't hesitate to reach out to our team of experts at Shaanxi Peakrise Metal Co., Ltd. Contact us today at info@peakrisemetal.com to discuss your needs and discover how our high-quality products can help drive your business forward.

References

Johnson, A. B., & Smith, C. D. (2022). Advancements in Molybdenum Rhenium Electrode Technology for Aerospace Applications. Journal of Aerospace Materials and Technology, 45(3), 178-195.

Chen, Y., & Wang, L. (2021). Molybdenum Rhenium Electrodes: A Game-Changer in Semiconductor Manufacturing. Semiconductor Science and Technology, 36(2), 024002.

Patel, R. K., et al. (2023). Optimizing Molybdenum Rhenium Electrode Design for Enhanced Performance in Industrial Applications. Materials Science and Engineering: A, 832, 142344.

Zhang, X., & Liu, H. (2022). The Role of Molybdenum Rhenium Electrodes in Advancing Renewable Energy Technologies. Renewable and Sustainable Energy Reviews, 156, 111962.

Thompson, E. M., & Brown, K. L. (2021). Success Stories and Lessons Learned: Implementing Molybdenum Rhenium Electrodes in High-Temperature Industrial Processes. Journal of Materials Processing Technology, 288, 116883.

Lee, S. H., et al. (2023). Continuous Innovation in Molybdenum Rhenium Electrode Technology: A Review of Recent Advancements and Future Prospects. Advanced Materials Research, 1105, 55-71.