Understanding Titanium Plates and Their Applications

Composition and Grades of Titanium Plates

Titanium plates are manufactured from either commercially pure titanium or specialized titanium alloys, offering multiple grades to accommodate a wide range of industrial and engineering applications. Commonly used grades include TA1, TA2, TC4 (Ti-6Al-4V), and TA9, each selected based on specific mechanical properties, corrosion resistance, and thermal performance requirements. These plates combine high strength, low density, and excellent formability, making them suitable for critical applications where durability and weight reduction are essential, such as aerospace structures, chemical processing equipment, and medical devices requiring long-term biocompatibility.

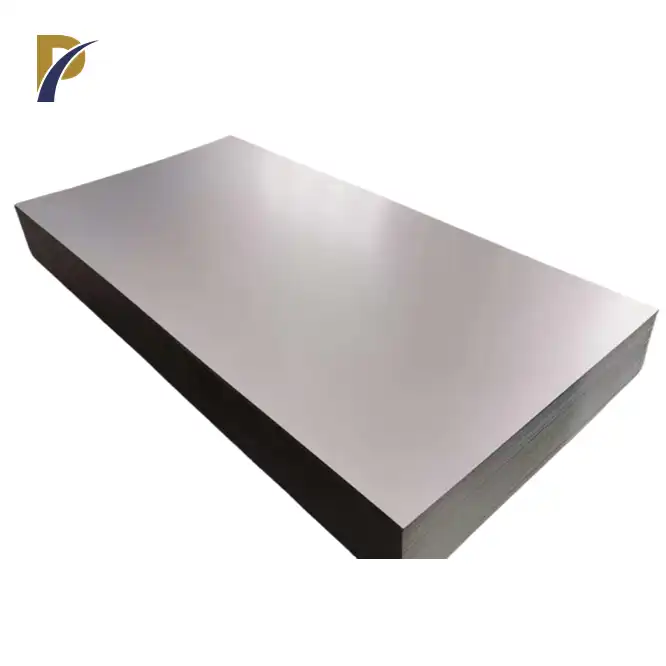

Key Properties of Titanium Plates

Titanium plates possess a unique combination of properties that make them invaluable across demanding applications. They feature low density (approximately 4.51 g/cm³), high tensile strength, outstanding fatigue resistance, and excellent resistance to extreme temperatures and aggressive chemical environments. These attributes contribute to their durability, dimensional stability, and long-term reliability. The exceptional corrosion resistance of titanium, including resistance to seawater and various acids, further enhances its performance, ensuring minimal maintenance and extended service life in sectors such as aerospace, marine, and chemical processing industries.

Industries Benefiting from Titanium Plates

Titanium plates are widely applied across multiple industries due to their superior mechanical and chemical properties. In aerospace, they are integral to aircraft frames, engine components, and structural reinforcements, where weight reduction and strength are critical. The medical sector uses titanium for surgical implants, prosthetics, and precision instruments due to its biocompatibility. Chemical processing plants rely on titanium's resistance to corrosion for reaction vessels and heat exchangers. Additionally, marine industries benefit from titanium plates in shipbuilding, offshore platforms, and desalination equipment, ensuring long-lasting performance in highly corrosive environments.

|

|

Selecting the Right Titanium Plate Supplier in China

Evaluating Supplier Credentials and Certifications

When choosing a titanium plate supplier, it's essential to verify their credentials. Look for manufacturers certified to international standards such as ISO 9001 for quality management. Certifications specific to titanium production, like ASTM B265 or GB/T3621, indicate adherence to rigorous quality controls.

Assessing Production Capabilities and Technology

Top-tier suppliers invest in advanced manufacturing technologies. Facilities equipped with vacuum arc melting furnaces, precision CNC machining, and state-of-the-art testing equipment ensure consistent, high-quality titanium plates. Evaluate a supplier's capacity to meet your specific requirements in terms of plate dimensions, surface finishes, and tolerances.

Importance of Quality Control Measures

Reputable titanium plate manufacturers implement stringent quality control processes. This includes material testing for chemical composition, mechanical properties, and microstructure analysis. Inquire about their inspection procedures, non-destructive testing capabilities, and quality assurance protocols to ensure you receive plates that meet your exacting standards.

Navigating the Purchasing Process

Specifying Your Titanium Plate Requirements

When purchasing titanium plates, clearly communicating your requirements is essential to ensure you receive components that meet your application needs. Provide detailed specifications, including the desired titanium grade, exact dimensions such as thickness, width, and length, and any surface finish preferences. Highlight any special treatments, such as annealing or coating, that may be necessary. Additionally, discuss acceptable tolerance levels and any industry-specific certifications required. This comprehensive approach helps suppliers understand your expectations and reduces the risk of errors or delays in the procurement process.

Understanding Pricing and Lead Times

Titanium plate pricing is influenced by factors such as raw material costs, selected grade, and processing complexity. To make informed decisions, request quotations from multiple suppliers and evaluate not only the cost but also the lead times and minimum order quantities. Custom specifications, tighter tolerances, or special treatments can affect both pricing and production schedules. By carefully considering these variables, buyers can better plan budgets, ensure timely delivery, and avoid unexpected delays, ultimately achieving a cost-effective procurement process without compromising quality or performance.

Logistics and Delivery Considerations

Efficient logistics are critical when purchasing titanium plates, particularly for international shipments. Coordinate shipping arrangements with your supplier, taking into account packaging requirements to protect plates from damage during transit. Ensure all necessary export documentation and customs clearance procedures are properly managed. Experienced suppliers often provide guidance on the most efficient shipping methods, including air, sea, or land transport, and can help anticipate potential delays. Proper planning of logistics ensures that titanium plates arrive on schedule, in optimal condition, and ready for immediate use in your manufacturing or engineering operations.

Conclusion

Sourcing titanium plates from China offers significant advantages in terms of quality, cost-effectiveness, and production capabilities. By thoroughly evaluating suppliers, understanding the nuances of titanium plate specifications, and carefully managing the procurement process, buyers can secure high-quality materials that meet their project requirements. Remember to prioritize suppliers who demonstrate a commitment to quality, offer transparent communication, and possess the technical expertise to support your specific needs.

FAQs

What are the most common grades of titanium plates available from Chinese suppliers?

Chinese suppliers typically offer grades such as TA1, TA2 (equivalent to Grade 1 and 2), and TC4 (Grade 5 or Ti-6Al-4V).

How do I ensure the quality of titanium plates from a Chinese manufacturer?

Look for suppliers with ISO certifications, request material test certificates, and consider third-party inspections before shipment.

What surface finishes are available for titanium plates?

Common finishes include pickling, sandblasting, and bright annealing, depending on the application requirements.

Why Choose Shaanxi Peakrise Metal Co., Ltd.?

Shaanxi Peakrise Metal Co., Ltd. stands out as a premier titanium plate supplier and manufacturer in China. With our state-of-the-art production facilities, rigorous quality control processes, and extensive experience in titanium alloy fabrication, we deliver superior products tailored to diverse industry needs. Our commitment to innovation, customer satisfaction, and global standards sets us apart in the market. For inquiries or to discuss your titanium plate requirements, contact us at info@peakrisemetal.com.

References

Liu, Y., & Zhang, L. (2020). Advances in Titanium Plate Manufacturing Techniques in China. Journal of Materials Engineering and Performance, 29(8), 5112-5124.

Wang, X., et al. (2019). Quality Control Measures in Chinese Titanium Industry: A Comprehensive Review. International Journal of Minerals, Metallurgy and Materials, 26(3), 291-300.

Chen, H., & Li, W. (2021). Titanium Plate Applications in Aerospace: Chinese Market Analysis. Aerospace Science and Technology, 108, 106377.

Zhang, S., et al. (2018). Corrosion Resistance of Titanium Plates in Marine Environments: A Comparative Study of Chinese and International Standards. Corrosion Science, 139, 83-96.

Li, J., & Wu, Y. (2022). Sourcing Strategies for Titanium Plates from China: Insights for Global Buyers. Journal of Supply Chain Management, 58(2), 3-21.

Tan, X., et al. (2023). Advancements in Titanium Plate Production Technologies: A Focus on Chinese Manufacturers. Materials Today: Proceedings, 70, 123-130.