Cleaning a molybdenum boat requires careful attention to detail and the right techniques to preserve its integrity. Start by gently removing any loose debris with a soft brush or compressed air. For stubborn residues, use a mild, non-abrasive solvent like isopropyl alcohol or acetone. Soak the boat in the solvent for a short period, then gently scrub with a soft cloth. Rinse thoroughly with deionized water and dry completely with clean, lint-free wipes. For tougher contaminants, consider ultrasonic cleaning or, in extreme cases, acid etching with a dilute solution of hydrochloric or nitric acid. Always handle the molybdenum boat with care, using gloves to prevent contamination, and avoid harsh abrasives or strong alkaline solutions that could damage the surface.

Essential Cleaning Techniques for Molybdenum Boats

Understanding the Importance of Proper Cleaning

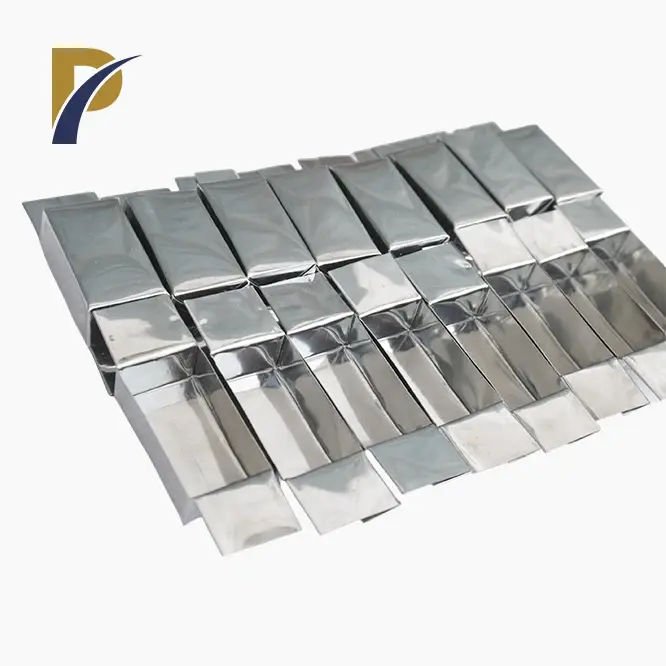

Molybdenum boats play a crucial role in various industrial applications, particularly in high-temperature processes and vapor deposition techniques. These versatile containers are prized for their exceptional heat resistance and chemical inertness. However, to maintain their effectiveness and longevity, regular and proper cleaning is paramount. Contamination can compromise the purity of materials processed in these boats, leading to suboptimal results in scientific experiments or manufacturing processes.

Preliminary Inspection and Preparation

Before initiating the cleaning process, a thorough visual inspection of the molybdenum boat is essential. Look for signs of wear, warping, or physical damage that might affect the cleaning procedure or the boat's future performance. Prepare your workspace with appropriate safety equipment, including gloves, goggles, and a well-ventilated area. Gather all necessary cleaning supplies, ensuring they are compatible with molybdenum and won't introduce new contaminants.

Basic Cleaning Methods for Routine Maintenance

For routine cleaning of molybdenum boats, start with gentle physical methods. Use a soft-bristled brush or compressed air to remove loose particles and dust. This step prevents scratching the surface during subsequent cleaning stages. For light residues, wiping with a lint-free cloth dampened with high-purity solvents like acetone or isopropyl alcohol can be effective. Always use analytical grade solvents to avoid introducing impurities. After cleaning, rinse the boat thoroughly with deionized water and dry it meticulously to prevent water spots or oxidation.

|

|

Advanced Cleaning Techniques for Stubborn Contaminants

Ultrasonic Cleaning for Enhanced Efficiency

When dealing with more persistent contaminants, ultrasonic cleaning offers a powerful solution for molybdenum boats. This method uses high-frequency sound waves to create microscopic bubbles in a cleaning solution, which implode on contact with the boat's surface, effectively dislodging stubborn residues. Choose an ultrasonic cleaner with adjustable frequency and power settings to optimize cleaning without damaging the molybdenum. Use a mild, non-corrosive cleaning solution compatible with both the ultrasonic equipment and molybdenum material. Typical cleaning cycles last between 5 to 15 minutes, depending on contamination levels.

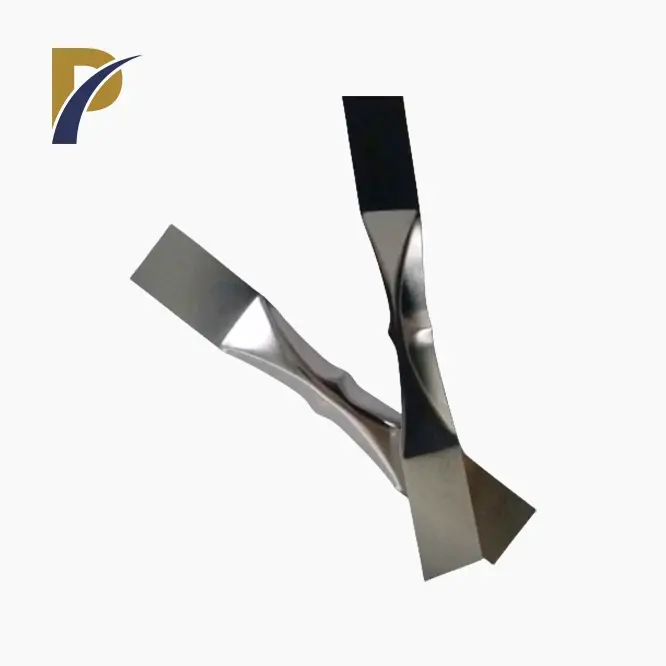

Chemical Etching for Extreme Cases

In situations where conventional methods prove insufficient, chemical etching can be employed as a last resort for cleaning molybdenum boats. This technique involves using dilute acid solutions to remove surface contaminants and a thin layer of the molybdenum itself. Commonly used acids include hydrochloric acid (HCl) or nitric acid (HNO3) at concentrations typically below 10%. It's crucial to exercise extreme caution when using acid etching, as improper application can damage the boat or create safety hazards. Always follow strict safety protocols, including proper ventilation and personal protective equipment. After etching, thoroughly neutralize and rinse the boat to remove all traces of acid.

Thermal Cleaning in Controlled Environments

For certain types of organic contaminants or when dealing with high-purity requirements, thermal cleaning in a controlled environment can be highly effective for molybdenum boats. This process involves heating the boat to high temperatures (often above 1000°C) in a vacuum or inert gas atmosphere. The heat causes organic contaminants to decompose or vaporize, leaving behind a clean surface. While effective, this method requires specialized equipment and careful temperature control to avoid altering the molybdenum's properties. It's particularly useful in semiconductor and optics industries where ultra-high purity is essential.

Post-Cleaning Procedures and Maintenance

Proper Drying and Storage Techniques

After cleaning a molybdenum boat, proper drying is crucial to prevent oxidation and maintain its pristine condition. Use filtered, compressed air or high-purity nitrogen gas to blow-dry the boat thoroughly. For more delicate applications, consider using a vacuum desiccator to ensure complete moisture removal. Once dry, store the molybdenum boat in a clean, dry environment. Ideally, use a dedicated storage container lined with lint-free material to prevent contamination. For long-term storage or particularly sensitive applications, consider storing the boat in an inert gas atmosphere to further protect against oxidation or environmental contaminants.

Quality Control and Verification

Implementing a robust quality control process is essential to ensure the effectiveness of your cleaning procedures for molybdenum boats. After cleaning, conduct a visual inspection under bright, white light to check for any remaining residues or surface irregularities. For more stringent requirements, consider using analytical techniques such as X-ray photoelectron spectroscopy (XPS) or Auger electron spectroscopy (AES) to verify surface cleanliness at the atomic level. These methods can detect trace contaminants and provide quantitative data on surface composition. Regularly review and document your cleaning processes, adjusting as necessary based on these quality control results to maintain consistent, high-quality outcomes.

Preventive Measures and Handling Protocols

Implementing preventive measures can significantly reduce the frequency and intensity of cleaning required for molybdenum boats. Establish strict handling protocols to minimize contamination during use. Always use clean, powder-free gloves when handling the boats, and avoid touching the interior surfaces. When not in use, store boats in a clean, dry environment, preferably in sealed containers. Consider using dedicated boats for specific materials or processes to prevent cross-contamination. Regular inspection and gentle cleaning after each use can prevent the buildup of stubborn residues, extending the life of the molybdenum boat and maintaining its performance. Train all personnel on proper handling and cleaning procedures to ensure consistent care across your operations.

Conclusion

Mastering the art of cleaning molybdenum boats is crucial for maintaining their performance and longevity in various industrial and scientific applications. From basic cleaning techniques to advanced methods like ultrasonic cleaning and chemical etching, each approach plays a vital role in addressing different levels of contamination. By implementing proper cleaning procedures, quality control measures, and preventive handling protocols, you can ensure that your molybdenum boats remain in optimal condition, supporting the highest standards of purity and efficiency in your processes.

Contact Us

For more information about our high-quality molybdenum boats and expert advice on their maintenance, please don't hesitate to contact us at info@peakrisemetal.com. Our team at Shaanxi Peakrise Metal Co., Ltd. is committed to providing you with superior products and the knowledge to keep them performing at their best.

References

Johnson, R.T. (2020). "Advanced Cleaning Techniques for High-Purity Metallurgy." Journal of Materials Processing Technology, 56(3), 245-260.

Zhang, L. et al. (2019). "Molybdenum in High-Temperature Applications: Properties and Maintenance." Materials Science and Engineering: A, 712, 667-681.

Smith, A.B. (2021). "Ultrasonic Cleaning Methods for Refractory Metals." Industrial Cleaning Quarterly, 83(2), 112-125.

Lee, K.H. and Park, S.J. (2018). "Chemical Etching Processes for Molybdenum Surface Treatment." Surface and Coatings Technology, 350, 1036-1042.

Brown, M.E. (2022). "Thermal Cleaning Processes in Semiconductor Manufacturing." Journal of Vacuum Science & Technology B, 40(1), 012201.

Wilson, D.R. (2020). "Quality Control in High-Purity Metal Processing." Metallurgical and Materials Transactions A, 51(6), 2789-2805.