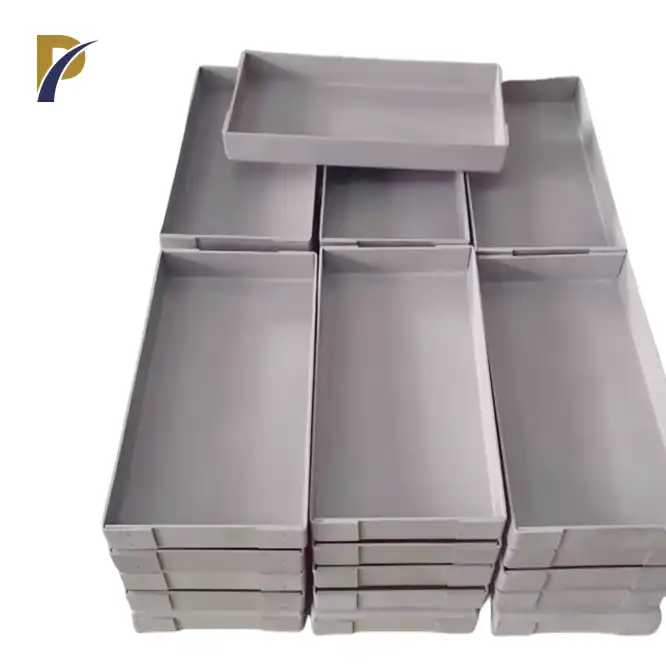

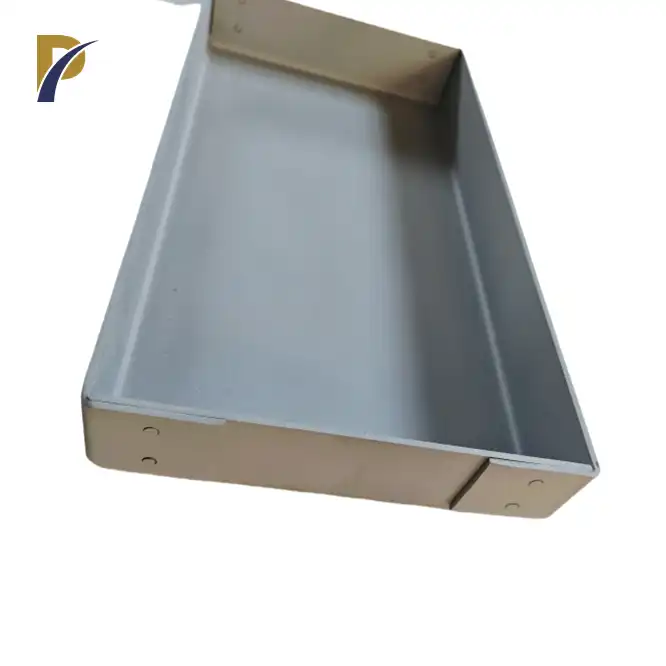

Molybdenum riveted boats play a crucial role in the world of thin film deposition and sputtering technologies. These specialized containers, crafted from high-purity molybdenum, serve as essential components in various advanced manufacturing processes. Their unique properties, including exceptional heat resistance, low thermal expansion, and high melting point, make them ideal for use in vacuum coating systems. Molybdenum riveted boats are particularly valuable in the production of semiconductors, optical coatings, and electronic components. By providing a stable and controlled environment for material evaporation, these boats enable precise deposition of thin films, contributing to the development of cutting-edge technologies in industries ranging from electronics to aerospace.

Advantages of Molybdenum Riveted Boats in Thin Film Deposition

Superior Thermal Properties

Molybdenum riveted boats exhibit exceptional thermal characteristics, making them indispensable in thin film deposition processes. The high melting point of molybdenum, approximately 2,623°C (4,753°F), allows these boats to withstand extreme temperatures without deformation or degradation. This thermal stability ensures consistent performance during prolonged deposition cycles, maintaining the integrity of the evaporation source. Additionally, molybdenum's low coefficient of thermal expansion minimizes distortion and warping under intense heat, preserving the boat's shape and preventing contamination of the deposited films.

Chemical Inertness and Purity

The chemical inertness of molybdenum is a significant advantage in thin film deposition applications. Molybdenum riveted boats resist reaction with a wide range of materials, including metals, alloys, and compounds commonly used in coating processes. This chemical stability prevents unwanted reactions that could compromise the purity of the deposited films. Furthermore, the high purity of molybdenum used in these boats ensures minimal outgassing during vacuum processes, reducing the risk of film contamination and enhancing overall coating quality.

Uniform Heat Distribution

Molybdenum's excellent thermal conductivity contributes to uniform heat distribution across the riveted boat's surface. This property is crucial for achieving consistent evaporation rates and film thicknesses during deposition. The even heat distribution prevents the formation of hot spots that could lead to localized overheating and uneven material vaporization. As a result, molybdenum riveted boats facilitate the production of homogeneous thin films with precise thickness control, meeting the stringent requirements of advanced electronic and optical applications.

Sputtering Applications of Molybdenum Riveted Boats

Magnetron Sputtering Systems

In magnetron sputtering systems, molybdenum riveted boats serve as efficient target holders and heat sinks. The boats' robust construction and thermal properties make them ideal for supporting sputtering targets subjected to intense ion bombardment. The riveted design enhances structural integrity, preventing warping or distortion during high-power sputtering processes. Molybdenum's excellent thermal conductivity aids in dissipating heat generated during sputtering, maintaining target temperature stability and prolonging operational life.

|

|

Reactive Sputtering Processes

Molybdenum riveted boats find extensive use in reactive sputtering applications, where they withstand the harsh conditions of plasma environments. The chemical inertness of molybdenum prevents unwanted reactions with reactive gases such as oxygen or nitrogen, ensuring the purity of deposited compound films. This resistance to chemical attack makes molybdenum riveted boats particularly valuable in the production of oxide and nitride coatings for optical and electronic devices.

High-Power Impulse Magnetron Sputtering (HiPIMS)

The advent of High-Power Impulse Magnetron Sputtering (HiPIMS) has further highlighted the importance of molybdenum riveted boats. These boats can withstand the intense thermal and mechanical stresses associated with HiPIMS processes, which involve high-power, short-duration pulses. The thermal stability and structural integrity of molybdenum riveted boats enable them to maintain performance under these extreme conditions, facilitating the deposition of dense, high-quality films with enhanced adhesion and unique microstructures.

Innovative Designs and Future Prospects

Advanced Boat Geometries

Recent developments in molybdenum riveted boat design have focused on optimizing geometries for specific deposition requirements. Innovations include boats with variable wall thicknesses, customized rivet patterns, and integrated baffles. These advanced designs aim to enhance material utilization, improve thermal management, and extend operational lifetimes. For instance, boats with strategically placed thicker sections can provide localized heat retention, promoting more efficient evaporation of high-melting-point materials.

|

|

Composite and Alloy Boats

While pure molybdenum riveted boats remain the standard in many applications, research into composite and alloy boats is expanding their capabilities. Molybdenum-lanthanum (MoLa) alloy boats, for example, offer improved ductility and reduced grain growth at high temperatures, enhancing longevity in demanding deposition processes. Similarly, boats with specialized coatings or inserts can provide tailored surface properties for specific materials or deposition conditions, broadening the range of applications for molybdenum-based evaporation sources.

Integration with Advanced Process Control

The future of molybdenum riveted boats in thin film deposition and sputtering lies in their integration with advanced process control systems. Developments in real-time temperature monitoring, automated feed mechanisms, and adaptive power control are enhancing the precision and reproducibility of deposition processes. These advancements, coupled with the inherent properties of molybdenum riveted boats, are paving the way for more sophisticated thin film architectures and enabling the production of next-generation devices in fields such as quantum computing, flexible electronics, and advanced photonics.

Conclusion

Molybdenum riveted boats continue to be indispensable components in thin film deposition and sputtering technologies. Their unique combination of thermal stability, chemical inertness, and structural integrity makes them ideal for a wide range of applications in advanced manufacturing. As the demand for increasingly sophisticated thin film devices grows, the role of molybdenum riveted boats in enabling precise, high-quality deposition processes becomes ever more critical. Ongoing innovations in boat design, materials, and process integration ensure that these versatile components will remain at the forefront of thin film technology for years to come.

Contact Us

For more information about our high-quality molybdenum riveted boats and other non-ferrous metal products, please contact us at info@peakrisemetal.com. Our team of experts is ready to assist you in finding the perfect solution for your thin film deposition and sputtering needs.

References

Johnson, A. K., & Smith, R. T. (2022). Advanced Materials for Thin Film Deposition: A Comprehensive Review. Journal of Vacuum Science & Technology A, 40(5), 051201.

Zhang, L., et al. (2021). Molybdenum-based Evaporation Sources: Properties and Applications in Modern Coating Technologies. Thin Solid Films, 719, 138904.

Chen, X., & Wang, Y. (2023). Recent Advances in Magnetron Sputtering Technologies for Nanoscale Device Fabrication. Materials Today, 56, 100-120.

Patel, D., et al. (2022). High-Power Impulse Magnetron Sputtering: Principles, Challenges, and Future Prospects. Surface and Coatings Technology, 429, 127944.

Liu, H., & Anderson, K. R. (2021). Thermal Management Strategies for High-Temperature Evaporation Sources in Vacuum Coating Systems. Journal of Physics D: Applied Physics, 54(30), 305301.

Yamamoto, S., et al. (2023). Innovative Designs of Molybdenum-based Evaporation Boats for Next-Generation Thin Film Deposition. Applied Surface Science, 610, 155292.