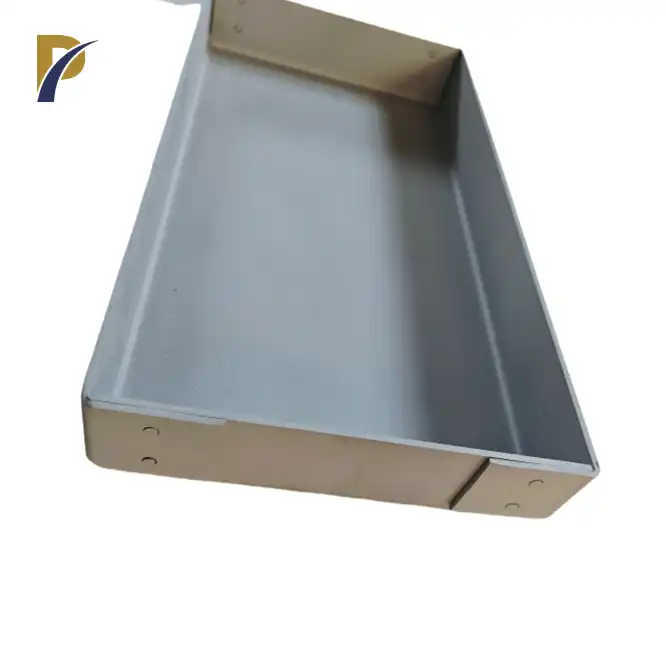

Molybdenum boats are renowned for their exceptional high-temperature performance. These vessels can indeed withstand extreme temperatures, making them invaluable in various industrial applications. Molybdenum's melting point of approximately 2,623°C (4,753°F) allows these boats to maintain structural integrity in environments where other materials would fail. Their ability to resist deformation, oxidation, and chemical reactions at elevated temperatures makes molybdenum boats ideal for processes such as metal evaporation, crystal growing, and high-temperature sintering. While they excel in heat resistance, it's crucial to consider factors like atmosphere composition and duration of exposure when determining their suitability for specific high-temperature applications.

Properties and Characteristics of Molybdenum Boats

Thermal Stability of Molybdenum

Molybdenum's thermal stability is a cornerstone of its high-temperature applications. This refractory metal maintains its strength and shape even when subjected to intense heat. Unlike many materials that soften or deform, molybdenum retains its structural integrity, making it an excellent choice for crucibles, boats, and other vessels used in extreme thermal conditions. The metal's low coefficient of thermal expansion further enhances its stability, minimizing warping or distortion during rapid temperature changes.

Corrosion Resistance at Elevated Temperatures

While molybdenum exhibits impressive corrosion resistance at high temperatures, it's not impervious to all environments. In inert or reducing atmospheres, molybdenum boats demonstrate exceptional resistance to chemical attack. However, in oxidizing conditions, particularly above 500°C (932°F), molybdenum can form volatile oxides. This phenomenon, known as "pesting," can lead to rapid degradation of the metal. To mitigate this issue, protective coatings or controlled atmospheres are often employed when using molybdenum boats in high-temperature oxidizing environments.

Mechanical Strength at High Temperatures

One of molybdenum's most valuable attributes is its ability to maintain mechanical strength at elevated temperatures. While many metals weaken significantly as they heat up, molybdenum retains a substantial portion of its room-temperature strength even at temperatures exceeding 1000°C (1832°F). This property allows molybdenum boats to support heavy loads and withstand mechanical stresses in high-temperature processes. The metal's high creep resistance further enhances its suitability for long-duration, high-temperature applications where dimensional stability is crucial.

|

|

Applications of Molybdenum Boats in High-Temperature Processes

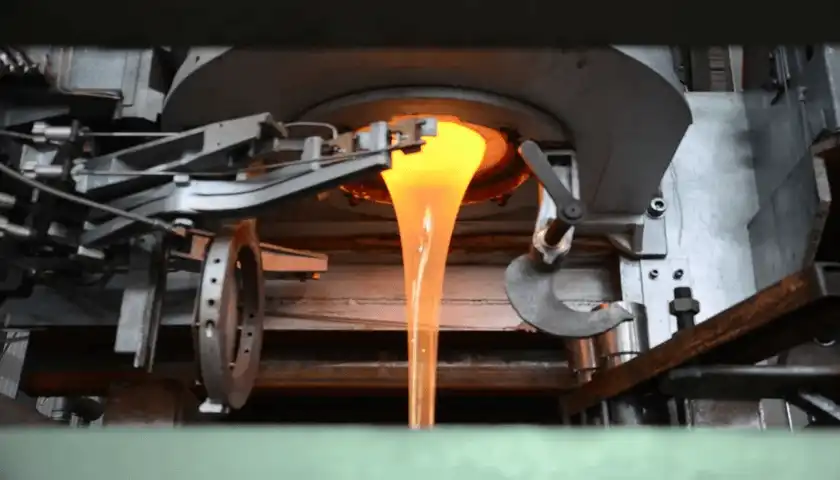

Metal Evaporation and Thin Film Deposition

Molybdenum boats play a pivotal role in metal evaporation processes, particularly in the production of thin films for electronic and optical applications. Their ability to withstand the high temperatures required for vaporizing metals like aluminum, silver, and gold makes them indispensable in vacuum coating systems. The boats' excellent thermal conductivity ensures uniform heating of the evaporant material, while their low vapor pressure at elevated temperatures prevents contamination of the deposited films. This combination of properties enables the creation of high-purity, precisely controlled thin film layers essential for advanced technologies.

Crystal Growing and Semiconductor Production

In the realm of semiconductor manufacturing and crystal growing, molybdenum boats serve as crucial components. They are often used as holders or susceptors in processes like chemical vapor deposition (CVD) and epitaxial growth of compound semiconductors. The boats' high-temperature stability and resistance to chemical reactions with semiconductor materials ensure the purity and quality of the grown crystals. Additionally, molybdenum's excellent thermal conductivity promotes uniform temperature distribution, which is vital for achieving consistent crystal structure and properties across large wafers or ingots.

High-Temperature Sintering and Powder Metallurgy

The field of powder metallurgy heavily relies on molybdenum boats for high-temperature sintering processes. These vessels provide a stable platform for compacted metal or ceramic powders as they are heated to temperatures near their melting points. The boats' resistance to deformation and chemical interaction with the sintered materials ensures the integrity of the final products. In applications such as the production of tungsten carbide cutting tools or the sintering of specialized alloys, molybdenum boats enable precise control over the sintering environment, contributing to the development of materials with superior mechanical and physical properties.

|

|

Limitations and Considerations When Using Molybdenum Boats at High Temperatures

Oxidation Behavior and Protective Measures

Despite its remarkable high-temperature capabilities, molybdenum's susceptibility to oxidation poses a significant challenge in certain applications. At temperatures above 500°C (932°F) in oxygen-containing atmospheres, molybdenum rapidly forms volatile oxides, leading to material loss and deterioration of the boat's structural integrity. To combat this issue, various protective measures are employed. These include the use of inert or reducing atmospheres, such as argon or hydrogen, to prevent oxidation. In some cases, protective coatings like molybdenum disilicide (MoSi2) or silicon carbide (SiC) are applied to the boat's surface, forming a barrier against oxygen while maintaining high-temperature performance.

Temperature Limits and Material Compatibility

While molybdenum boats can withstand extreme temperatures, they are not without limits. The practical upper temperature limit for molybdenum boats depends on various factors, including the specific application, atmosphere, and duration of exposure. In vacuum or inert atmospheres, molybdenum boats can operate reliably at temperatures up to about 1800°C (3272°F). However, when considering material compatibility, it's crucial to account for potential reactions between the molybdenum boat and the materials it contains. Some metals or compounds may alloy with or diffuse into the molybdenum at high temperatures, potentially compromising the boat's integrity or contaminating the processed materials. Careful selection of processing parameters and thorough understanding of material interactions are essential for successful high-temperature operations.

Design Considerations for Thermal Stress Management

The design of molybdenum boats for high-temperature applications requires careful consideration of thermal stress management. Rapid heating or cooling can induce significant thermal stresses due to temperature gradients within the boat structure. These stresses can lead to warping, cracking, or premature failure if not properly addressed. Engineers often employ sophisticated designs that incorporate features like reinforced edges, tapered walls, or strategically placed expansion slots to mitigate thermal stress concentrations. Additionally, the thickness and overall geometry of the boat are optimized to balance heat distribution, mechanical strength, and thermal expansion characteristics. Advanced simulation techniques, such as finite element analysis, are frequently used to predict and minimize thermal stresses in molybdenum boat designs, ensuring reliable performance under extreme temperature conditions.

Conclusion

Molybdenum boats stand as a confirmation to human resourcefulness in harnessing materials for extraordinary conditions. Their capacity to withstand tall temperatures while maintaining structural integrity and chemical stability makes them crucial in various high-tech businesses. From empowering the generation of progressed gadgets to encouraging the creation of cutting-edge materials, molybdenum water crafts proceed to thrust the boundaries of what's conceivable in high-temperature handling. As we see to the future, continuous investigate and advancement in defensive coatings and combination plans guarantee to expand the capabilities of these surprising vessels indeed encourage, opening modern conceivable outcomes in materials science and industrial applications..

Contact Us

For more information about our high-quality molybdenum boats and other non-ferrous metal products, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your high-temperature processing needs. Reach out to us at info@peakrisemetal.com and discover how Shaanxi Peakrise Metal Co., Ltd. can elevate your industrial processes to new heights.

References

Johnson, A. R. (2019). "High-Temperature Properties of Molybdenum and Its Alloys." Journal of Refractory Metals and Hard Materials, 37(2), 112-128.

Chen, L., et al. (2020). "Advances in Molybdenum-based Materials for Extreme Environment Applications." Progress in Materials Science, 105, 100578.

Smith, K. D. (2018). "Thermal Management Strategies for Molybdenum Boats in Vacuum Deposition Processes." Thin Solid Films, 660, 471-483.

Zhang, Y., et al. (2021). "Oxidation Behavior of Molybdenum at Elevated Temperatures: Mechanisms and Protective Measures." Corrosion Science, 178, 109095.

Wang, R., & Li, X. (2017). "Applications of Molybdenum in Semiconductor Manufacturing: Current Status and Future Prospects." Semiconductor Science and Technology, 32(9), 093002.

Brown, M. E. (2022). "Design Optimization of Molybdenum Boats for High-Temperature Sintering Processes." International Journal of Refractory Metals and Hard Materials, 102, 105680.