The Unique Properties of Molybdenum Wires

Molybdenum wires possess a remarkable combination of properties that set them apart from other metallic materials. These characteristics contribute to their widespread use and make them essential in various industrial applications.

High Temperature Resistance

One of the standout qualities of molybdenum wires is their exceptional resistance to high temperatures. With a melting point of around 2,623°C (4,753°F), it retain their strength, stability, and electrical properties even under extreme heat. This remarkable thermal resilience makes them indispensable in applications like aerospace, electronics, and high-temperature manufacturing, where other materials might quickly lose their integrity or degrade. Molybdenum wires are crucial for maintaining performance and reliability in environments that demand enduring heat resistance and durability.

Excellent Electrical Conductivity

Because of their outstanding electrical conductivity—a unique attribute despite their high melting point—molybdenum wires operate better under challenging circumstances. They are therefore ideal for usage in specialist electrical components like vacuum tubes, X-ray tubes, and high-temperature heating elements where effective current flow and heat resistance are crucial. Their ability to maintain conductivity under adverse conditions ensures reliable and efficient operation in a wide range of industrial and scientific applications.

Superior Corrosion Resistance

The endurance and dependability of molybdenum wires are increased by their exceptional resistance to corrosion, particularly in non-oxidizing settings. Because of their ability to withstand corrosion, they are perfect for applications in fields like electronics, aerospace, and chemical processing where they may come into touch with corrosive materials, harsh chemicals, or gases. Because of this, it keeps their integrity, requiring fewer repairs over time and guaranteeing steady performance.

|

|

Industrial Applications of Molybdenum Wires

The exceptional properties of molybdenum wires have led to their adoption across a wide range of industries. Let's explore some of the key sectors where these versatile wires play a crucial role.

Aerospace and Aviation

In the aerospace sector, molybdenum wires are essential for building rocket propulsion systems and high-performance aircraft engines. They are essential for these demanding applications because of their remarkable capacity to tolerate extremely high temperatures and maintain structural integrity in the face of tremendous heat. Thermocouples, sensors, heating elements, and other vital parts that must withstand the high mechanical and thermal strains of flight commonly use wires. This guarantees dependable performance, efficiency, and safety in cutting-edge aircraft technologies.

Electronics and Semiconductor Manufacturing

The electronics industry depends on molybdenum wires for numerous applications, particularly in semiconductor manufacturing. These wires are used as heating elements in furnaces for silicon crystal growth and wafer processing, where precise temperature control is crucial. Their exceptional resistance to high temperatures, combined with excellent electrical conductivity, ensures uniform heat distribution, vital for achieving the consistency and quality required in semiconductor production. This makes it indispensable in creating reliable and high-performance electronic components.

| Name | Specific properties | Application |

| Molybdenum wire electrolytic cleaning | Electrolysis can be removed | mandrel curl |

| Molybdenum wire hydrogen cleaning | Can remove hydrogen from the atmosphere | For making different types of bulb holders |

Medical and Healthcare

Molybdenum wires are increasingly used in the medical field, especially in imaging technologies like X-ray systems. In X-ray tubes, molybdenum wire targets are essential for producing high-quality diagnostic images. The material’s ability to endure the extreme heat generated during X-ray production without losing its strength or performance is critical for ensuring accurate and reliable imaging. This makes molybdenum wires a key component in the advancement of medical imaging and patient care.

The Future of Molybdenum Wires in Industry

With new uses and developments anticipated, the need for molybdenum wires is anticipated to increase as technology develops further.

Emerging Technologies

Molybdenum wires are being investigated for new applications in advanced technologies. For example, because of their high heat resistance and minimal plasma contamination characteristics, wires are being studied as possible materials for plasma-facing components in nuclear fusion research.

Sustainable Energy Solutions

There are now more opportunities for molybdenum wire applications thanks to the drive towards renewable energy sources. These wires are utilized in the creation of thin-film photovoltaic cells, which results in more robust and effective solar energy solutions.

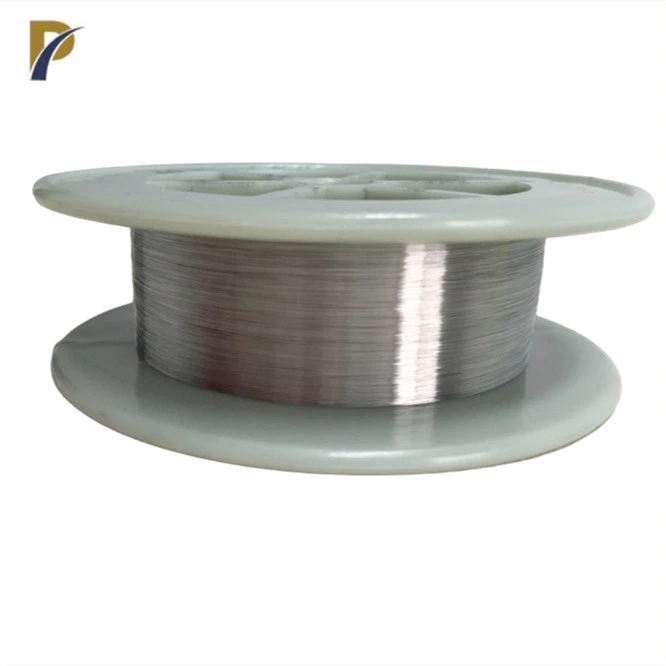

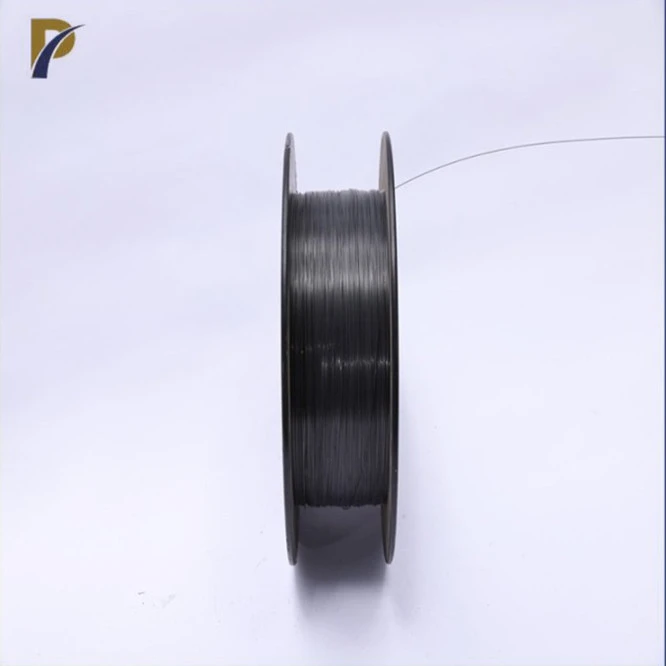

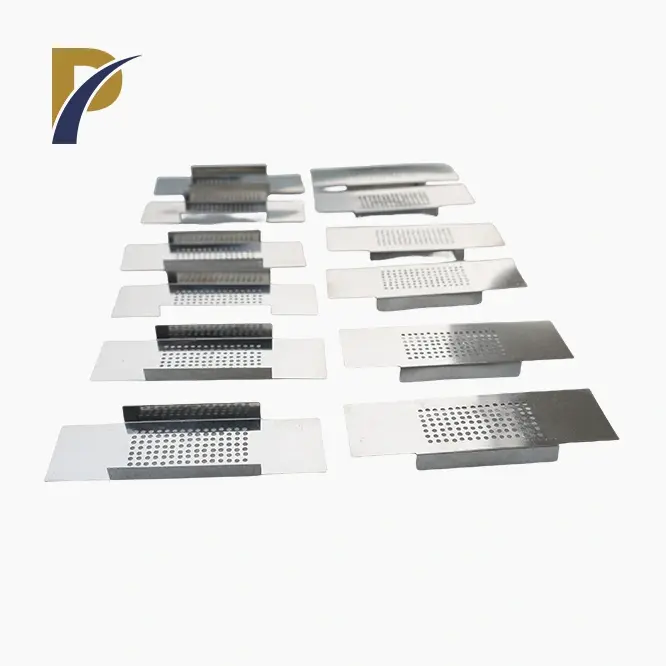

Products Produced By Shaanxi Peakrise Metal Co.,Ltd

|

|

|

|

|

|

|

|

|

Advancements in Material Science

The goal of current material science research is to further improve the characteristics of molybdenum wires. In order to increase their use in even more varied applications, scientists are looking into ways to make them more ductile and formable while preserving their resilience to high temperatures.

Conclusion

Molybdenum wires have proven indispensable in a variety of industries due to their unique mix of properties. Because of their exceptional durability to high temperatures, great electrical conductivity, and resistance to corrosion, these wires remain indispensable for the development of technology and innovation. Molybdenum wires' versatility and reliability ensure their ongoing importance in shaping engineering and manufacturing practices as industries shift and new issues emerge.

Contact Us

Would you like additional information about how molybdenum wires might help your particular application or industry? Get in touch with Shaanxi Peakrise Metal Co., Ltd. for superior molybdenum wire goods and knowledgeable guidance. Contact us at info@peakrisemetal.com to talk about your requirements and find out how our extensive selection of non-ferrous metal solutions may help your projects succeed.

References

Johnson, R. T. (2019). "Advanced Materials in Aerospace: The Role of Molybdenum." Journal of Aerospace Engineering, 42(3), 215-230.

Zhang, L., & Liu, Y. (2020). "Molybdenum in Modern Electronics: Applications and Innovations." Semiconductor Science and Technology, 35(8), 084001.

Patel, S., et al. (2018). "High-Temperature Properties of Molybdenum Wires for Extreme Environment Applications." Materials Science and Engineering: A, 730, 312-321.

Nakamura, K., & Tanaka, T. (2021). "Advancements in Molybdenum Wire Technology for Medical Imaging." Medical Physics, 48(6), 3142-3155.

Fernandez, A., & Rodriguez, C. (2022). "Sustainable Energy Solutions: The Potential of Molybdenum in Solar Cell Manufacturing." Renewable Energy, 179, 1256-1268.

Smith, J. D., & Brown, E. R. (2023). "Future Prospects of Molybdenum Wires in Industry: A Comprehensive Review." Materials Today, 56, 100-115.