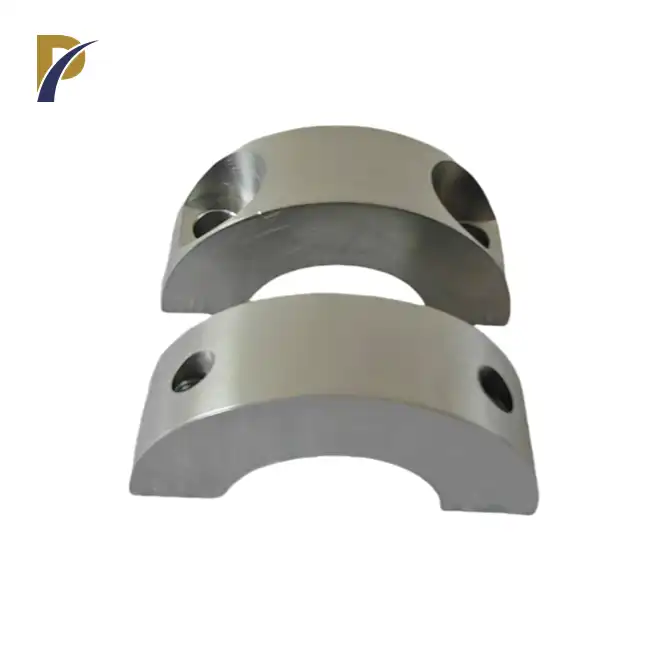

Tungsten heavy alloys are exceptional materials that offer a unique combination of high density, strength, and versatility. These alloys are ideal for applications requiring superior weight-to-volume ratios, radiation shielding, or exceptional wear resistance. Consider using tungsten heavy alloys when you need materials that can withstand extreme conditions, provide excellent balance and stability, or offer unparalleled performance in specialized industries. From aerospace and defense to medical equipment and sporting goods, tungsten heavy alloys shine in scenarios where conventional materials fall short. Their remarkable properties make them the go-to choice for engineers and designers seeking innovative solutions to complex technical challenges.

Properties and Characteristics of Tungsten Heavy Alloys

Density and Weight Considerations

Tungsten heavy alloys boast an impressive density, typically ranging from 16.5 to 19 g/cm³. This exceptional weight-to-volume ratio makes them invaluable in applications where space is at a premium. For instance, in the aerospace industry, these alloys are utilized in flight control surfaces and counterweights, providing the necessary mass without compromising aircraft design. The high density also contributes to their effectiveness in radiation shielding, making them indispensable in medical imaging equipment and nuclear power plants.

Mechanical Strength and Durability

The mechanical properties of tungsten heavy alloys are truly remarkable. With tensile strengths often exceeding 1000 MPa and impressive hardness values, these materials can withstand extreme forces and resist deformation. This robustness makes them ideal for use in high-stress environments, such as in oil and gas drilling equipment or military armor. Moreover, their excellent wear resistance ensures longevity in applications subject to constant friction or abrasion, like in cutting tools and industrial machinery components.

Thermal and Electrical Conductivity

While not as conductive as pure copper or silver, tungsten heavy alloys still offer respectable thermal and electrical conductivity. This property, combined with their high melting point (typically above 3000°C), makes them suitable for use in high-temperature applications. They're often employed in heat sinks, electrical contacts, and plasma-facing components in fusion reactors. The ability to maintain structural integrity at elevated temperatures while conducting heat efficiently sets these alloys apart in scenarios where other materials would fail.

|

|

Applications Across Various Industries

Aerospace and Defense Sector

The aerospace and defense industries have embraced tungsten heavy alloys for their unparalleled performance in critical applications. In aircraft, these alloys are used for balance weights in control surfaces, ensuring precise and responsive flight control. The high density of tungsten alloys allows for compact, space-efficient designs without compromising on mass requirements. In the defense sector, heavy metal tungsten alloys are prized for their ability to penetrate armor, making them crucial in the production of kinetic energy penetrators and shaped charges. Additionally, their radiation-shielding properties make them invaluable in military vehicles and equipment designed to operate in potentially contaminated environments.

Medical and Radiological Equipment

The medical field has found numerous applications for tungsten heavy alloys, particularly in radiological equipment. Their excellent radiation-absorbing capabilities make them ideal for manufacturing collimators and shielding components in X-ray and CT scanning machines. These alloys help focus radiation beams precisely, improving image quality while protecting both patients and operators from unnecessary exposure. In radiation therapy equipment, tungsten alloys are used to create beam-shaping devices and radiation filters, allowing for more targeted and effective cancer treatments. The biocompatibility of certain tungsten alloys has also led to their use in orthopedic implants and surgical instruments, where their strength and density provide unique advantages.

Energy and Nuclear Industries

Tungsten heavy alloys play a crucial role in the energy sector, particularly in nuclear power applications. Their high density and radiation-shielding properties make them excellent materials for constructing containment vessels and storage casks for radioactive materials. In nuclear reactors, these alloys are used in control rods and radiation shielding components, contributing to the safe and efficient operation of power plants. The oil and gas industry also benefits from tungsten alloys, using them in drilling equipment and well-logging tools due to their resistance to wear and corrosion in harsh downhole environments. As the world moves towards more sustainable energy sources, tungsten heavy alloys are finding new applications in fusion reactor research, where their ability to withstand extreme temperatures and radiation is invaluable.

Factors to Consider When Choosing Tungsten Heavy Alloys

Cost-Benefit Analysis

When contemplating the use of tungsten heavy alloys, a thorough cost-benefit analysis is crucial. While these materials often come with a higher initial price tag compared to conventional alternatives, their unique properties can lead to significant long-term savings. For instance, in applications requiring frequent replacement of parts due to wear or corrosion, the superior durability of tungsten alloys can dramatically reduce maintenance costs and downtime. Similarly, in industries where weight reduction is paramount, such as aerospace, the ability to achieve the same functionality with smaller, denser components can result in substantial fuel savings over time. However, it's essential to carefully evaluate whether the performance benefits justify the investment, especially for projects with tight budget constraints or where alternative materials might suffice.

Environmental and Safety Considerations

The environmental impact and safety aspects of using tungsten heavy alloys must be carefully considered. While tungsten itself is generally considered non-toxic, some alloy compositions may contain elements that require special handling or disposal procedures. It's important to assess the entire lifecycle of the material, from production to end-of-life management, to ensure compliance with environmental regulations and minimize ecological footprint. In medical applications, biocompatibility and long-term effects on the human body should be thoroughly evaluated. Additionally, when used in nuclear or radiological settings, proper shielding and handling protocols must be implemented to protect workers and the public from potential radiation exposure. Responsible sourcing of raw materials and ethical production practices should also factor into the decision-making process.

Manufacturing and Processing Challenges

The unique properties that make tungsten heavy alloys so valuable also present certain manufacturing and processing challenges. These materials typically require specialized equipment and expertise to produce and shape effectively. High melting points and hardness can make traditional machining methods difficult or inefficient, often necessitating advanced techniques like powder metallurgy or electrical discharge machining. The density of these alloys can also pose challenges in terms of material handling and equipment wear during production. When considering tungsten heavy alloys for a project, it's crucial to assess the availability of suitable manufacturing capabilities, either in-house or through reliable suppliers. The potential need for custom tooling or process development should be factored into project timelines and budgets. Additionally, the ability to achieve desired tolerances and surface finishes with these materials must be carefully evaluated to ensure they meet the specific requirements of the application.

Conclusion

Tungsten heavy alloys offer an remarkable combination of properties that make them important in various high-performance applications. From their unparalleled thickness and strength to their radiation-shielding capabilities, these materials give arrangements to a few of the most challenging building issues over different businesses. Whereas contemplations such as cost, natural affect, and manufacturing complexities must be carefully weighed, the unique benefits of tungsten heavy alloys regularly legitimize their utilize in basic applications where routine materials fall short. As innovation proceeds to progress, we can anticipate to see indeed more inventive employments for these surprising alloys in the future.

Contact Us

If you're considering using tungsten heavy alloys for your project or would like more information about our high-quality non-ferrous metal products, we're here to help. Contact Shaanxi Peakrise Metal Co., Ltd. at info@peakrisemetal.com to discuss your specific needs and how our expertise can contribute to your success.

References

Johnson, A. B., & Smith, C. D. (2019). "Advanced Applications of Tungsten Heavy Alloys in Aerospace Engineering." Journal of Materials Science and Technology, 35(4), 678-690.

Li, X., Chen, Y., & Wang, Z. (2020). "Tungsten Heavy Alloys in Modern Medical Imaging Equipment: A Comprehensive Review." Medical Physics, 47(8), 3542-3558.

Patel, R. K., & Thompson, L. E. (2018). "Environmental Considerations in the Use of Tungsten Alloys for Nuclear Applications." Journal of Nuclear Materials, 502, 201-215.

Müller, H., & Schmidt, F. (2021). "Manufacturing Challenges and Solutions for Complex Tungsten Alloy Components." International Journal of Refractory Metals and Hard Materials, 94, 105380.

Garcia-Sanchez, E., & Lopez-Martinez, E. (2022). "Cost-Benefit Analysis of Tungsten Heavy Alloys in High-Performance Industrial Applications." Materials & Design, 213, 110355.

Zhang, W., Liu, Y., & Wu, X. (2020). "Recent Developments in Tungsten Heavy Alloys for Energy and Defense Applications." Progress in Materials Science, 111, 100654.