Understanding Molybdenum Glass Melting Electrodes

Composition and Properties of Molybdenum Electrodes

Molybdenum electrodes for glass melting are crafted from high-purity molybdenum, a refractory metal known for its exceptional heat resistance and electrical conductivity. These electrodes boast a melting point of approximately 2,623°C (4,753°F), making them ideal for withstanding the extreme temperatures encountered in glass furnaces. The unique properties of molybdenum, including its low thermal expansion coefficient and high creep resistance, contribute to the electrode's ability to maintain structural integrity under harsh conditions.

Role in Glass Manufacturing

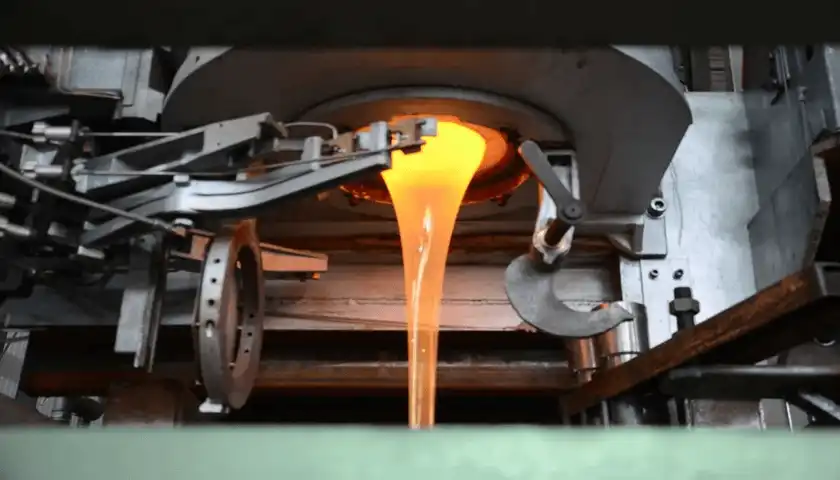

Molybdenum electrodes for glass melting serve as the primary heat source in electric glass furnaces. By conducting electricity through the molten glass, these electrodes generate the intense heat necessary to melt and refine raw materials into high-quality glass products. The electrodes' performance directly impacts the efficiency of the glass melting process, influencing factors such as energy consumption, glass quality, and production output.

Advantages Over Alternative Materials

Molybdenum offers distinct advantages over other electrode materials in glass melting applications. Its exceptional heat resistance enables it to operate at higher temperatures, leading to improved glass quality and higher production rates. Furthermore, molybdenum's strong resistance to corrosion and oxidation in molten glass extends electrode lifespan, reducing the need for frequent replacements. This durability minimizes downtime and enhances overall process efficiency. These properties make molybdenum an ideal choice for glass manufacturers seeking reliable performance, reduced maintenance, and consistent, high-quality results in demanding melting environments.

|

|

Factors Influencing Electrode Lifespan

Operating Temperature and Thermal Stress

The operating temperature of the glass furnace significantly impacts the lifespan of molybdenum glass melting electrodes. Higher temperatures accelerate wear and corrosion processes, potentially reducing electrode longevity. Thermal stress, caused by temperature fluctuations during furnace operation or maintenance cycles, can lead to electrode cracking or deformation. Careful temperature control and gradual heating/cooling procedures are essential for mitigating these effects and extending electrode life.

Glass Composition and Chemical Interactions

The chemical composition of the glass being melted plays a crucial role in electrode wear. Certain glass formulations, particularly those containing high levels of alkali or alkaline earth oxides, can be more corrosive to molybdenum electrodes. The presence of impurities or aggressive components in the glass batch may accelerate electrode degradation through chemical reactions or enhanced oxidation. Optimizing glass formulations and maintaining strict control over raw material purity can help minimize these detrimental effects.

Electrical Current and Power Density

The electrical current and power density passing through molybdenum electrodes are crucial in determining their lifespan. High current densities can cause localized overheating, accelerate oxidation, and lead to premature electrode failure. On the other hand, insufficient current can result in inadequate heating and reduced efficiency in processes like glass melting. To optimize both performance and longevity, it is essential to carefully manage power levels and properly size the electrodes. Achieving the right balance between current density and heat generation ensures efficient operation while extending the lifespan of molybdenum electrodes in demanding industrial applications.

Strategies for Maximizing Electrode Lifespan

Proper Installation and Maintenance Procedures

Ensuring correct installation of molybdenum glass melting electrodes is paramount to their longevity. This includes proper alignment, secure connections, and adequate insulation to prevent current leakage. Regular maintenance, such as inspecting for signs of wear or damage, cleaning electrode surfaces, and tightening connections, can help identify and address potential issues before they lead to premature failure. Implementing a comprehensive maintenance schedule and training personnel in proper handling techniques are crucial steps in maximizing electrode lifespan.

|

|

Optimizing Furnace Operating Conditions

Fine-tuning furnace operating parameters can significantly impact the lifespan of molybdenum electrodes. This includes maintaining stable temperature profiles, minimizing thermal shocks during start-up and shutdown procedures, and ensuring uniform current distribution across the electrodes. Implementing advanced control systems and monitoring technologies can help optimize furnace conditions, reducing electrode stress and prolonging their operational life.

Innovative Electrode Designs and Materials

Advancements in electrode design and material science offer promising avenues for extending the lifespan of molybdenum glass melting electrodes. Innovations such as composite electrodes, featuring protective coatings or reinforced structures, can enhance resistance to corrosion and oxidation. Additionally, ongoing research into molybdenum alloys and novel manufacturing techniques may yield electrodes with improved durability and performance characteristics, further extending their operational lifespan in glass melting applications.

Conclusion

The lifespan of molybdenum glass melting electrodes is a complex interplay of material properties, operating conditions, and maintenance practices. While typical lifespans can range from several months to over a year, depending on the specific application and operating environment, implementing the strategies discussed can significantly extend electrode longevity. By understanding the factors influencing electrode wear and adopting best practices in furnace operation and maintenance, glass manufacturers can optimize their processes, reduce costs, and improve overall production efficiency.

Contact Us

Are you looking to enhance your glass melting operations with high-quality molybdenum electrodes? Shaanxi Peakrise Metal Co., Ltd. offers cutting-edge solutions tailored to your specific needs. Contact us today at info@peakrisemetal.com to learn more about our molybdenum glass melting electrodes and how they can revolutionize your glass production process.