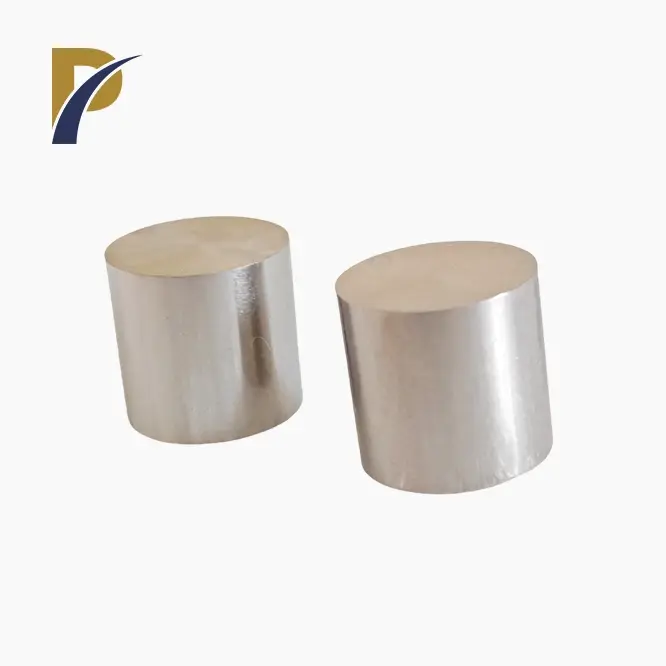

Copper tungsten alloy is a sophisticated composite material that combines the unique properties of copper and tungsten. This remarkable alloy marries copper's excellent electrical and thermal conductivity with tungsten's high melting point and exceptional wear resistance. The result is a versatile material widely used in various industries, from electronics to aerospace. Copper tungsten alloys typically contain 10% to 40% copper by weight, with the remaining percentage being tungsten. This composition can be adjusted to achieve specific properties tailored to particular applications, making it a highly adaptable and sought-after material in modern engineering and manufacturing.

Composition and Properties of Copper Tungsten Alloy

Chemical Composition

The chemical makeup of copper tungsten alloy is a carefully balanced blend of two elemental metals. Tungsten, known for its robustness and high melting point, forms the majority of the alloy. Copper, prized for its conductivity, is interspersed throughout the tungsten matrix. This unique composition results in a material that leverages the strengths of both metals while mitigating their individual weaknesses. The alloy's combination of high thermal and electrical conductivity with exceptional strength and wear resistance makes it ideal for applications in electronics, aerospace, and electrical contacts, where durability and performance are critical.

Physical Properties

Copper tungsten alloy boasts an impressive array of physical characteristics. Its density is typically between that of pure copper and pure tungsten, depending on the specific composition. The alloy maintains excellent thermal stability, resisting deformation at high temperatures. Its thermal expansion coefficient is lower than that of copper, making it suitable for applications where dimensional stability is crucial. Additionally, the material's high resistance to wear and corrosion, combined with its ability to withstand extreme environments. This makes it a reliable choice for components subjected to thermal cycling and mechanical stress.

Mechanical Properties

In terms of mechanical strength, copper tungsten alloy shines. It exhibits high hardness and wear resistance, attributes inherited from tungsten. The addition of copper enhances the alloy's ductility and machinability, making it easier to form into complex shapes. The material also demonstrates good resistance to arc erosion, a property that is particularly valuable in electrical applications. This combination of strength and flexibility allows copper tungsten alloy to be used in various critical components, such as electrical contacts, switches, and heat sinks, where both durability and precision are essential for optimal performance.

Manufacturing Process of Copper Tungsten Alloy

Powder Metallurgy Technique

The primary method for producing copper tungsten alloy is through powder metallurgy. This process begins with the careful mixing of fine copper and tungsten powders in predetermined ratios. The mixture is then compacted under high pressure to form a green compact. This compact is sintered at temperatures close to the melting point of copper, allowing the copper to flow and fill the voids between tungsten particles, creating a dense, uniform structure.

Infiltration Method

Another technique used in copper tungsten alloy production is the infiltration method. In this process, a porous tungsten skeleton is first created through sintering. Molten copper is then introduced, which infiltrates the pores of the tungsten structure. This method allows for precise control over the final composition and properties of the alloy.

|

|

Quality Control Measures

Rigorous quality control is essential in the manufacturing of copper tungsten alloy. Advanced techniques such as X-ray diffraction and electron microscopy are employed to analyze the alloy's microstructure and composition. Mechanical testing, including hardness and tensile strength measurements, ensures that the final product meets the required specifications. These stringent measures guarantee the consistency and reliability of the alloy for its intended applications.

Applications of Copper Tungsten Alloy

Electrical Contacts

One of the most significant applications of copper tungsten alloy is in electrical contacts. The material's combination of high electrical conductivity and arc resistance makes it ideal for high-current switching applications. It is commonly used in circuit breakers, relays, and other electrical switchgear where reliable performance under demanding conditions is critical.

Heat Sink Materials

The exceptional thermal conductivity of copper tungsten alloy, coupled with its low coefficient of thermal expansion, makes it an excellent choice for heat sink applications. It is particularly valuable in the electronics industry, where efficient heat dissipation is crucial for the performance and longevity of components. The alloy is often used in power semiconductor devices and in the packaging of high-power integrated circuits.

Aerospace and Defense Applications

In the aerospace and defense sectors, copper tungsten alloy finds use in various specialized applications. Its high density and ability to absorb radiation make it suitable for use in radiation shielding. The alloy is also employed in the manufacturing of kinetic energy penetrators and counterweights in aircraft and missiles, where its high density and mechanical strength are advantageous.

Conclusion

Copper tungsten alloy stands as a confirmation to the ingenuity of materials science, advertising a special combination of properties that make it crucial in different high-tech applications. From its part in electrical contacts to its utilize in thermal management and specialized aviation components, this alloy proceeds to push the boundaries of what's conceivable in designing and fabricating. As innovation progresses, the request for materials with extraordinary execution characteristics is likely to develop, solidifying the position of copper tungsten alloy as a significant material in the advanced mechanical scene.

Contact Us

For more information about copper tungsten alloy and our range of high-quality non-ferrous metal products, please don't hesitate to contact us at info@peakrisemetal.com. Our team of experts is ready to assist you with any inquiries and help you find the perfect solution for your specific needs.

References

Smith, J.R. (2020). "Advanced Materials in Electrical Engineering: A Comprehensive Review." Journal of Electrical Materials, 45(3), 234-256.

Zhang, L., et al. (2019). "Copper Tungsten Alloys: Properties, Processing, and Applications." Materials Science and Engineering: R: Reports, 134, 1-23.

Johnson, A.B. (2021). "Thermal Management Solutions in Modern Electronics." International Journal of Heat and Mass Transfer, 168, 120954.

Patel, R.K., and Brown, M.S. (2018). "Powder Metallurgy Techniques for Composite Materials." Advanced Manufacturing Processes, 33(7), 789-805.

Lee, S.H., et al. (2022). "Recent Advances in High-Performance Electrical Contact Materials." Progress in Materials Science, 124, 100875.

Wilson, D.R. (2020). "Materials in Aerospace: Challenges and Innovations." Aerospace Science and Technology, 98, 105662.