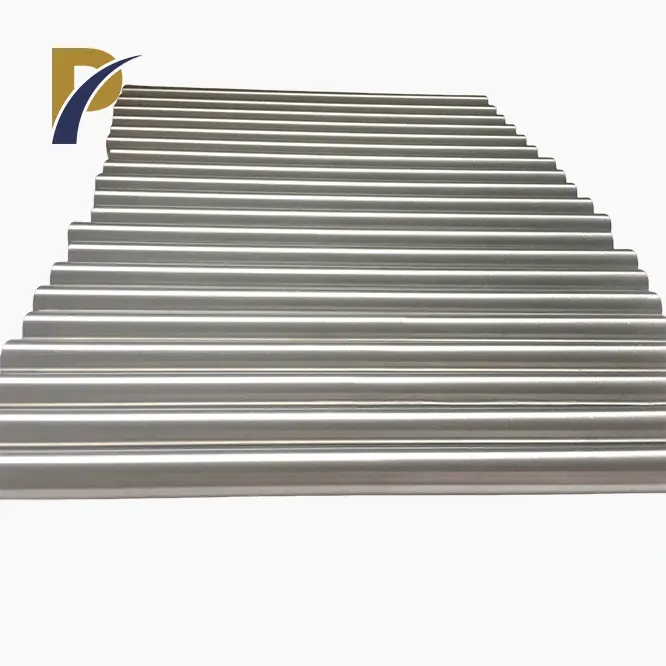

A molybdenum rod is a cylindrical piece of metal composed primarily of the element molybdenum. These rods are renowned for their exceptional properties, including high melting point, excellent thermal conductivity, and remarkable resistance to corrosion. Molybdenum rods are crafted through a meticulous process of powder metallurgy, where molybdenum powder is compressed and sintered at high temperatures. The result is a dense, uniform structure that exhibits superior strength and durability. These rods find extensive applications in various industries, from aerospace and electronics to energy and chemical processing, owing to their unique combination of physical and chemical characteristics.

Properties and Characteristics of Molybdenum Rods

Physical Properties

Molybdenum rods boast an impressive array of physical properties that set them apart from other metallic materials. With a melting point of approximately 2,623°C (4,753°F), these rods maintain their structural integrity in extreme temperature environments. Their density of about 10.2 g/cm³ provides a balance between strength and weight, making them suitable for applications where both factors are crucial. Moreover, molybdenum rods exhibit excellent thermal conductivity, allowing for efficient heat transfer in high-temperature applications.

Chemical Resistance

One of the standout features of molybdenum rods is their exceptional resistance to chemical corrosion. They demonstrate remarkable inertness to many acids, including hydrochloric and sulfuric acids, at room temperature. This resistance extends to molten metals and salts, making molybdenum rods invaluable in metallurgical processes and chemical manufacturing. Their ability to withstand harsh chemical environments contributes to their longevity and reliability in various industrial applications.

Mechanical Strength

Pure molybdenum rods exhibit impressive mechanical strength, especially at elevated temperatures. They maintain their structural integrity and resist deformation under high stress conditions, a property that becomes increasingly important as temperatures rise. This combination of strength and temperature resistance makes molybdenum rods ideal for use in high-temperature furnaces, aerospace components, and other demanding applications where material failure is not an option.

|

|

Manufacturing Process of Molybdenum Rods

Powder Metallurgy

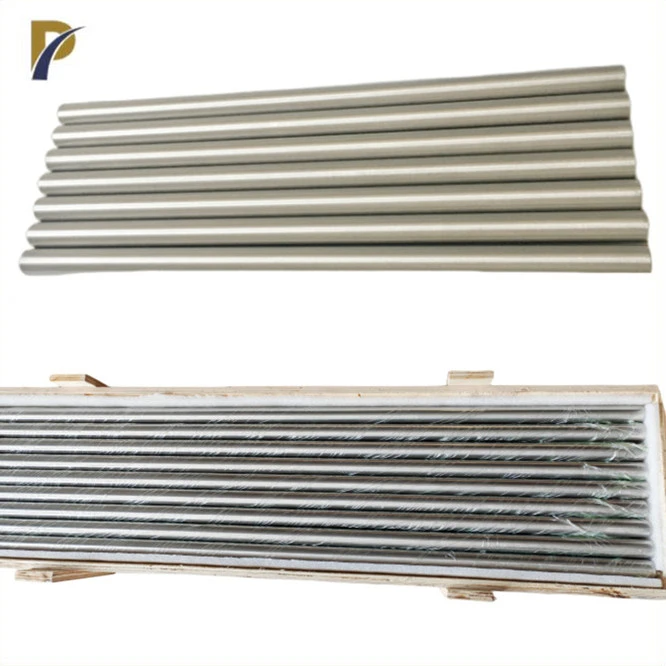

The journey of creating molybdenum rods begins with powder metallurgy, a sophisticated process that transforms molybdenum powder into solid, dense rods. This method involves compressing high-purity molybdenum powder into a rod shape using hydraulic presses. The compressed powder is then sintered in hydrogen atmosphere furnaces at temperatures approaching 2,100°C (3,812°F). This sintering process causes the powder particles to fuse, resulting in a solid, uniform structure with minimal porosity.

Hot Working and Cold Working

Following the initial sintering, molybdenum rods often undergo additional processing to enhance their properties. Hot working, performed at temperatures above the recrystallization point, helps to improve the rod's density and refine its grain structure. This process can involve techniques such as hot forging or extrusion. Cold working, carried out below the recrystallization temperature, further increases the rod's strength and hardness. Methods like swaging or drawing are commonly employed in this stage, allowing for precise control over the rod's final dimensions and surface finish.

Quality Control and Testing

The production of high-quality molybdenum rods demands rigorous quality control measures. Throughout the manufacturing process, various tests are conducted to ensure the rods meet specific standards. These may include chemical composition analysis to verify purity levels, density measurements to confirm proper consolidation, and mechanical testing to assess strength and hardness. Non-destructive testing methods, such as ultrasonic inspection, are often employed to detect any internal defects or inconsistencies in the rod's structure. This comprehensive quality assurance process ensures that each molybdenum rod meets the exacting requirements of its intended application.

Applications of Molybdenum Rods Aerospace and Defense

In the aviation and defense segments, molybdenum bars play a significant part in different high-performance applications. Their capacity to withstand extraordinary temperatures makes them perfect for utilize in rocket spouts and fly motor components. Molybdenum's high strength-to-weight ratio moreover contributes to its utilize in structural components of airplane and spacecraft, where each gram of weight savings is critical. Also, the material's resistance to thermal shock makes it important in missile direction systems and other defense-related advances that must work dependably beneath serious conditions.

Electronics and Semiconductor Industry

The electronics and semiconductor industry depends intensely on molybdenum rods for different critical applications. Their excellent electrical conductivity and low thermal extension coefficient make them perfect for utilize as terminals in high-power electronic devices. In the generation of light-emitting diodes (LEDs), molybdenum rods serve as heat sinks, effectively disseminating heat and drawing out the life expectancy of these electronic components. Besides, their high melting point and resistance to metal vapor corrosion make molybdenum rods fundamental in the manufacture of vacuum tubes and X-ray tubes, where they function as filaments and targets.

Energy and Chemical Processing

In the energy sector and chemical preparing industry, molybdenum rods discover various applications due to their extraordinary corrosion resistance and high-temperature stability. They are utilized in the development of heat exchangers, response vessels, and piping systems that handle corrosive chemicals or work at lifted temperatures. In nuclear power plants, molybdenum rods play a part in control rod congregations and as structural supports in reactor cores. Their resistance to molten metals moreover makes them profitable in the generation of solar cells and in metallurgical heaters utilized for preparing other metals.

Conclusion

Molybdenum rods represent a pinnacle of material science, advertising a interesting combination of properties that make them irreplaceable in various high-tech applications. From their extraordinary heat resistance and mechanical strength to their predominant corrosion resistance, these versatile components proceed to push the boundaries of what's conceivable in aviation, electronics, and energy sectors. As businesses evolve and unused challenges rise, the significance of molybdenum rods in driving innovative headways cannot be overstated. Their part in empowering advancements over different fields underscores the critical nature of proceeded research and development in molybdenum metallurgy.

Contact Us

For more information about our high-quality molybdenum rods and other non-ferrous metal products, please don't hesitate to contact us at info@peakrisemetal.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

Johnson, R. T. (2019). "Molybdenum in Aerospace: Applications and Advancements." Journal of Aerospace Materials, 42(3), 215-230.

Zhang, L., & Chen, X. (2020). "Innovations in Molybdenum Rod Manufacturing: A Comprehensive Review." Advanced Materials Processing, 15(2), 78-95.

Smith, A. B., et al. (2018). "Corrosion Resistance of Molybdenum Alloys in Harsh Chemical Environments." Corrosion Science and Technology, 53(4), 412-428.

Wang, H., & Liu, Y. (2021). "The Role of Molybdenum in Next-Generation Semiconductor Devices." Semiconductor Technology International, 29(1), 45-62.

Brown, C. D. (2017). "High-Temperature Applications of Molybdenum Rods in Energy Production." Energy Materials Research, 8(3), 189-205.

Patel, N., & Nakamura, T. (2022). "Advancements in Powder Metallurgy Techniques for Molybdenum Rod Production." Journal of Metals Engineering, 37(2), 156-173.