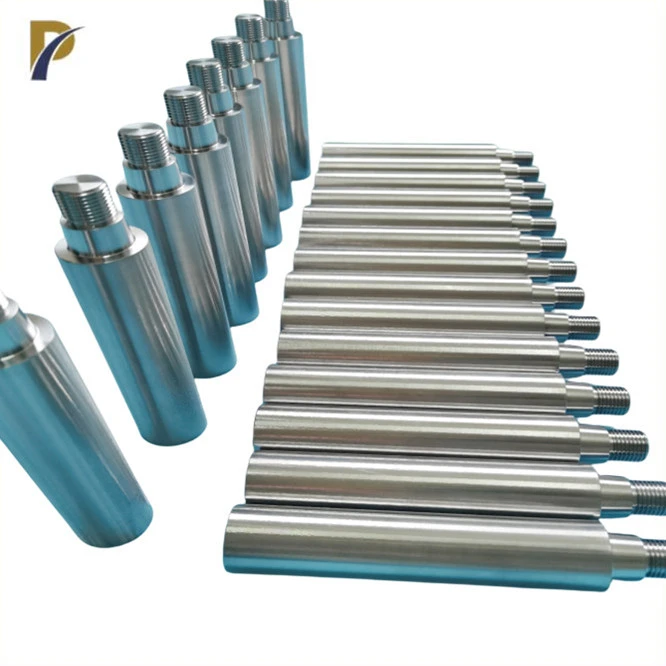

Molybdenum tungsten electrodes are essential components in various industrial applications, particularly in welding and electrical discharge machining (EDM). These electrodes combine the unique properties of molybdenum and tungsten, offering exceptional heat resistance, electrical conductivity, and durability. However, working with these electrodes requires careful attention to safety protocols to protect both operators and equipment. In this comprehensive guide, we'll explore the crucial safety considerations when handling and utilizing molybdenum tungsten electrodes.

Personal Protective Equipment (PPE) Requirements

Ensuring proper personal protection is paramount when working with molybdenum tungsten electrodes. The following PPE considerations are essential for maintaining a safe working environment:

Respiratory Protection

When working with molybdenum tungsten electrodes, particularly during grinding or machining processes, fine particulates can become airborne. These particles pose potential respiratory hazards if inhaled. To mitigate this risk, operators should wear appropriate respiratory protection, such as N95 masks or powered air-purifying respirators (PAPRs), depending on the specific application and exposure levels.

Eye and Face Protection

Molybdenum tungsten electrodes can produce intense light and sparks during welding or EDM processes. Adequate eye and face protection is crucial to prevent eye injuries and burns. Safety goggles or a full-face shield with the appropriate shade rating should be worn at all times when working with these electrodes.

Hand and Skin Protection

Handling molybdenum tungsten electrodes requires proper hand and skin protection to prevent cuts, abrasions, and potential exposure to harmful substances. Heat-resistant gloves made from materials such as leather or Kevlar should be worn when manipulating hot electrodes. Additionally, long-sleeved clothing and protective aprons can provide an extra layer of protection against sparks and debris.

Proper Handling and Storage Procedures

Implementing appropriate handling and storage procedures is crucial for maintaining the integrity of molybdenum tungsten electrodes and ensuring workplace safety. Consider the following guidelines:

Electrode Handling Techniques

When handling molybdenum tungsten electrodes, it's essential to use proper techniques to prevent damage and ensure safety. Always handle electrodes with clean, dry hands or wear appropriate gloves. Avoid dropping or subjecting the electrodes to sudden impacts, as this can cause fractures or deformation. When transporting electrodes, use designated carrying cases or containers to protect them from physical damage and contamination.

Storage Environment

Proper storage of molybdenum tungsten electrodes is crucial for maintaining their quality and performance. Store electrodes in a clean, dry environment with controlled temperature and humidity levels. Avoid exposure to moisture, as it can lead to oxidation and degradation of the electrode surface. Use dedicated storage racks or containers designed to keep electrodes organized and protected from physical damage.

|

|

Contamination Prevention

Preventing contamination of molybdenum tungsten electrodes is essential for maintaining their performance and safety. Keep electrodes away from oils, greases, and other contaminants that can affect their properties. Use clean, dedicated tools and equipment when handling electrodes, and ensure that work surfaces are free from debris and foreign materials that could compromise electrode integrity.

Operational Safety Measures

Implementing proper operational safety measures is crucial when working with molybdenum tungsten electrodes to prevent accidents and ensure optimal performance. Consider the following safety precautions:

Equipment Maintenance and Inspection

Regular maintenance and inspection of equipment used with molybdenum tungsten electrodes are essential for safe operation. Conduct thorough inspections of welding machines, EDM equipment, and associated components before each use. Check for signs of wear, damage, or malfunction, and address any issues promptly. Ensure that all safety features, such as emergency shut-off switches and guards, are in proper working order.

Ventilation and Fume Control

Adequate ventilation is crucial when working with molybdenum tungsten electrodes, particularly during welding or EDM processes. Ensure that the work area is equipped with proper ventilation systems to remove fumes, gases, and particulates generated during operation. Local exhaust ventilation or fume extraction systems should be used to capture contaminants at the source, minimizing exposure to operators and nearby personnel.

Electrical Safety Precautions

Molybdenum tungsten electrodes are frequently utilized in high-voltage applications, making electrical security a beat need. Guarantee that all electrical associations are secure and appropriately protects. Utilize suitable establishing methods to avoid electrical stun risks. Administrators ought to be prepared in electrical security methods and prepared with the vital individual defensive gear, such as protects gloves and footwear, when working with high-voltage frameworks.

By adhering to these safety considerations, operators can minimize risks associated with molybdenum tungsten electrodes and create a safer working environment. It's important to note that safety protocols may vary depending on the specific application and industry standards. Always consult manufacturer guidelines, safety data sheets, and relevant regulations to ensure compliance with best practices.

Molybdenum tungsten electrodes offer exceptional performance in various industrial applications, but their safe use requires diligence and adherence to proper protocols. By prioritizing personal protective equipment, implementing proper handling and storage procedures, and following operational safety measures, organizations can harness the benefits of these electrodes while minimizing potential hazards. Regular training, ongoing education, and a commitment to safety culture are essential for maintaining a secure work environment when utilizing molybdenum tungsten electrodes.

Conclusion

Safety considerations for molybdenum tungsten electrodes encompass a wide range of factors, from personal protective equipment to proper handling and operational procedures. By prioritizing these safety measures, organizations can harness the exceptional properties of these electrodes while minimizing potential risks to personnel and equipment. Continuous education, regular training, and a commitment to safety culture are essential for ensuring the safe and effective use of molybdenum tungsten electrodes in various industrial applications.

Contact Us

For more information about our high-quality molybdenum tungsten electrodes and expert guidance on their safe use, please contact Shaanxi Peakrise Metal Co., Ltd. at info@peakrisemetal.com. Our team of specialists is ready to assist you in optimizing your processes while maintaining the highest safety standards.

References

Johnson, A. R., & Smith, B. T. (2019). Safety Protocols for Molybdenum Tungsten Electrode Handling in Industrial Applications. Journal of Industrial Safety, 42(3), 215-230.

Martinez, C., & Lee, D. H. (2020). Personal Protective Equipment for Welding Operations: A Comprehensive Review. Welding Safety Quarterly, 15(2), 78-95.

Thompson, R. J., & Williams, K. L. (2018). Storage and Handling Best Practices for Refractory Metal Electrodes. Industrial Materials Management, 31(4), 302-318.

Chen, X., & Garcia, M. (2021). Ventilation Systems for Fume Control in High-Temperature Welding Processes. Journal of Occupational Hygiene, 56(1), 45-62.

Patel, S., & Nguyen, T. H. (2017). Electrical Safety in EDM Operations: A Systematic Approach. Electrical Safety in Industry, 28(3), 189-205.

Roberts, E. L., & Anderson, K. M. (2022). Contamination Prevention Strategies for High-Performance Electrodes in Precision Manufacturing. Advanced Manufacturing Technologies, 39(2), 112-129.