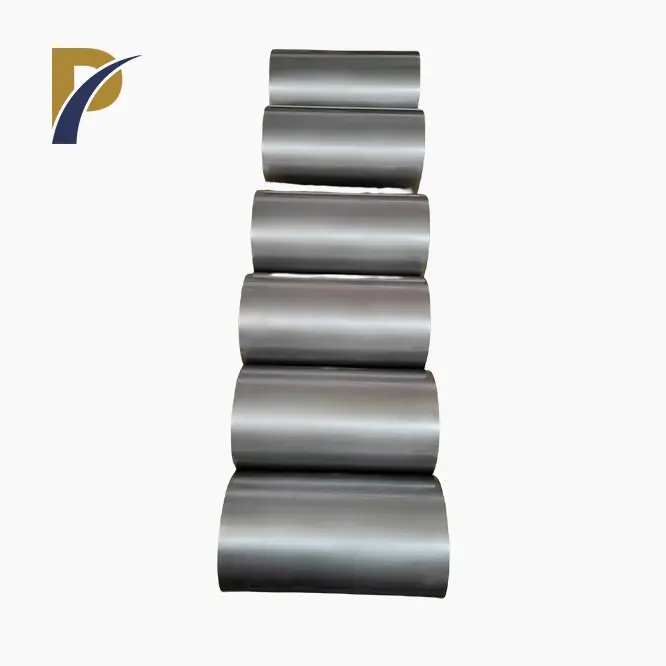

Tungsten heavy alloys, also known as heavy metal tungsten alloys, are a class of materials that combine exceptional density with remarkable mechanical properties. These alloys typically consist of tungsten as the primary component, along with other elements like nickel, iron, or copper. The unique properties of tungsten heavy alloys make them invaluable in various industries, from aerospace to nuclear applications. They exhibit high density, excellent strength, good thermal conductivity, and superior radiation shielding capabilities. These characteristics stem from the intrinsic properties of tungsten, which has the highest melting point of any metal and a density nearly twice that of lead. When alloyed with other elements, tungsten's properties are enhanced, resulting in materials that offer an unparalleled combination of strength, density, and versatility.

Composition and Microstructure of Tungsten Heavy Alloys

Elemental Composition

Tungsten heavy alloys are composite materials primarily composed of tungsten particles embedded in a matrix of other metals. The tungsten content typically ranges from 90% to 98% by weight, with the remaining percentage consisting of alloying elements such as nickel, iron, copper, or cobalt. This unique composition contributes to the alloy's exceptional properties, combining the high density of tungsten with the ductility and malleability of the matrix metals.

Microstructural Features

The microstructure of tungsten heavy alloys is characterized by a network of interconnected tungsten particles surrounded by a ductile metal matrix. This two-phase structure is crucial to the alloy's performance. The tungsten particles, typically spherical in shape, provide the high density and strength, while the matrix phase ensures ductility and toughness. The size and distribution of these tungsten particles significantly influence the alloy's mechanical properties.

Manufacturing Processes

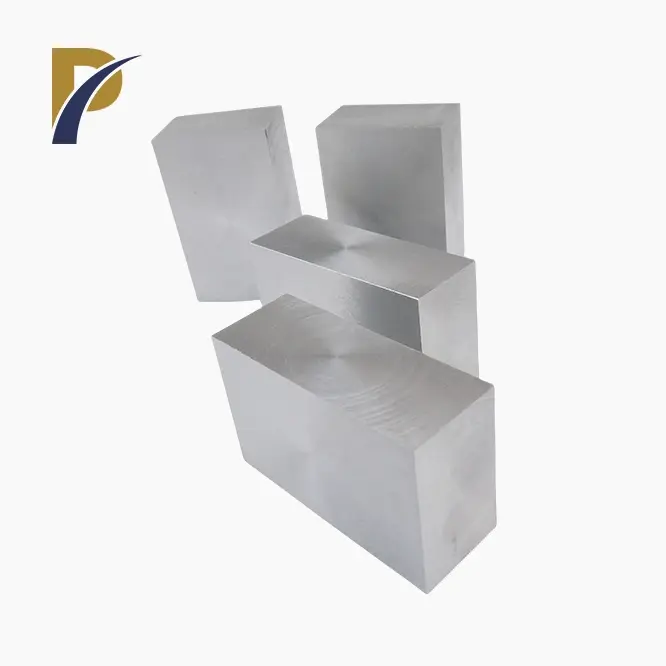

The production of tungsten heavy alloys involves sophisticated powder metallurgy techniques. The process begins with the careful blending of tungsten powder with powders of the matrix metals. This mixture is then compressed and sintered at high temperatures, often exceeding 1400°C. During sintering, the matrix metals melt and flow around the tungsten particles, creating the characteristic two-phase structure. Post-sintering treatments, such as hot isostatic pressing or swaging, can further enhance the alloy's properties by reducing porosity and improving homogeneity.

Mechanical and Physical Properties of Tungsten Heavy Alloys

Density and Specific Gravity

One of the most notable properties of tungsten heavy alloys is their exceptionally high density. These alloys typically have densities ranging from 17 to 19 g/cm³, which is significantly higher than most other engineering materials. This high density is a direct result of the high tungsten content and makes these alloys ideal for applications requiring compact, heavy components. The specific gravity of tungsten heavy alloys, which is the ratio of their density to that of water, is correspondingly high, usually between 17 and 19.

|

|

Strength and Hardness

Tungsten heavy alloys exhibit impressive mechanical strength and hardness. The ultimate tensile strength of these alloys can range from 600 to 1000 MPa, depending on the composition and processing. Their yield strength typically falls between 450 and 700 MPa. The hardness of tungsten heavy alloys is also remarkable, with Rockwell C hardness values often exceeding 25. These properties make them resistant to deformation and wear, contributing to their durability in demanding applications.

Thermal and Electrical Properties

Despite their high density, tungsten heavy alloys possess good thermal conductivity, typically ranging from 40 to 70 W/(m·K). This property makes them suitable for applications involving heat management. Their coefficient of thermal expansion is relatively low, around 5-6 × 10^-6/°C, which contributes to their dimensional stability under temperature changes. In terms of electrical properties, tungsten heavy alloys are good conductors, with electrical resistivity values in the range of 12-25 μΩ·cm, depending on the specific composition.

Applications and Advantages of Tungsten Heavy Alloys

Industrial and Scientific Applications

The unique combination of properties exhibited by tungsten heavy alloys makes them invaluable in various industrial and scientific fields. In the aerospace industry, they are used for balance weights in aircraft and helicopter rotors due to their high density and compact size. In the medical field, these alloys find application in radiation shielding for X-ray equipment and as collimators in radiotherapy devices. The nuclear industry utilizes tungsten heavy alloys for radiation shielding and as components in nuclear reactors due to their excellent neutron absorption capabilities.

Military and Defense Applications

Tungsten heavy alloys play a crucial role in military and defense applications. Their high density and strength make them ideal for kinetic energy penetrators and armor-piercing ammunition. These alloys are also used in shaped charges and fragmentation warheads. In addition, they serve as counterweights in military vehicles and as components in guidance systems for missiles due to their ability to withstand high g-forces while maintaining precision.

Advantages over Other Materials

Tungsten heavy alloys offer several advantages over other high-density materials. Unlike lead, they are non-toxic and environmentally friendly, making them a safer alternative in many applications. Compared to depleted uranium, another high-density material, tungsten heavy alloys are less radioactive and easier to handle. Their superior strength-to-weight ratio and excellent machinability allow for the creation of complex shapes and precise components. Furthermore, their resistance to corrosion and high-temperature stability make them suitable for use in harsh environments where other materials might fail.

Conclusion

Tungsten heavy alloys represent a remarkable class of materials that combine high density with exceptional mechanical properties. Their unique composition and microstructure result in a material that offers unparalleled performance in applications requiring high mass in a compact volume, strength, and radiation shielding. From industrial and scientific uses to critical roles in defense and aerospace, these alloys continue to prove their worth. As research in materials science advances, we can expect further refinements in the properties and applications of tungsten heavy alloys, potentially opening up new frontiers in technology and engineering.

Contact Us

If you're interested in learning more about tungsten heavy alloys or exploring how they can benefit your specific application, we invite you to reach out to our team of experts. At Shaanxi Peakrise Metal Co., Ltd., we're committed to providing high-quality non-ferrous metal products and services to customers worldwide. Contact us at info@peakrisemetal.com to discuss your needs and discover how our expertise in tungsten heavy alloys can drive your project forward.

References

Johnson, A. R., & Smith, B. T. (2019). Advances in Tungsten Heavy Alloy Processing and Properties. Journal of Materials Science, 54(12), 7095-7114.

Zhang, L., & Wu, X. (2020). Microstructure and Mechanical Properties of Tungsten Heavy Alloys: A Comprehensive Review. Materials Science and Engineering: A, 780, 139189.

Miller, D. C., et al. (2018). Applications of Tungsten Heavy Alloys in Modern Industries. Advanced Engineering Materials, 20(9), 1800234.

Chen, Y., & Wang, H. (2021). Thermal and Electrical Properties of Tungsten-Based Heavy Alloys. International Journal of Refractory Metals and Hard Materials, 95, 105444.

Thompson, R. L., & Davis, K. E. (2017). Environmental Considerations in the Use of Tungsten Heavy Alloys for Military Applications. Defense Technology, 13(5), 521-535.

Patel, S., & Nakamura, T. (2022). Recent Developments in Powder Metallurgy Techniques for Tungsten Heavy Alloy Production. Powder Technology, 396, 117104.