When utilizing molybdenum tube targets in various industrial applications, several environmental considerations come into play. These high-purity components, essential in thin film deposition processes, require careful handling and disposal to minimize ecological impact. Key environmental factors include energy consumption during production, potential waste generation, and the need for responsible recycling practices. Additionally, manufacturers must consider the extraction and processing of raw materials, implementing sustainable sourcing strategies. By addressing these aspects, industries can balance the technological benefits of molybdenum tube targets with environmental stewardship, ensuring a more sustainable approach to their use in advanced manufacturing processes.

Environmental Impact of Molybdenum Tube Target Production

Raw Material Extraction and Processing

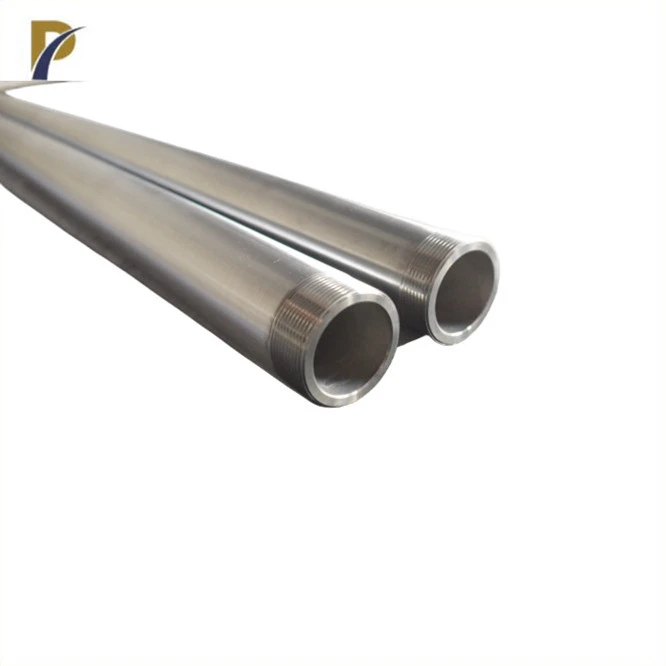

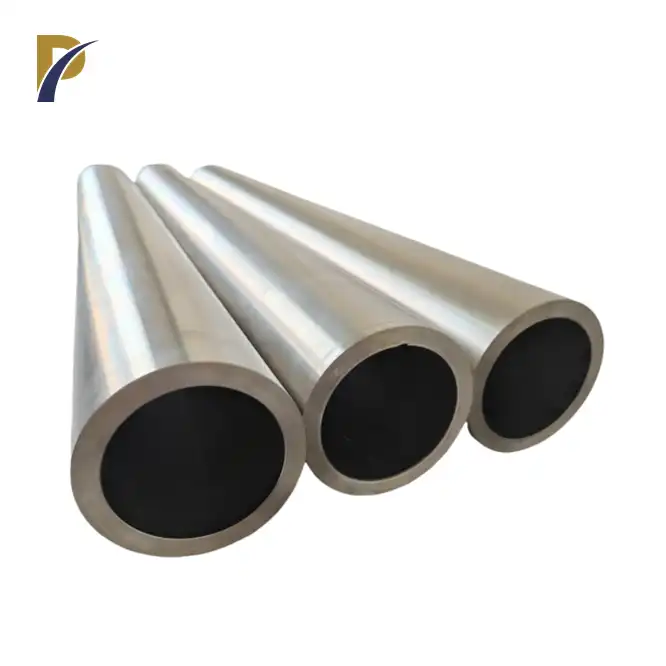

The journey of a molybdenum tube target begins with the extraction of molybdenum from its ore, primarily molybdenite. This process involves mining operations that can have significant environmental implications. Open-pit mining, often used for molybdenum extraction, can lead to habitat disruption and landscape alterations. Moreover, the processing of raw molybdenum requires substantial energy input and may produce waste materials that need careful management.

To mitigate these impacts, responsible mining practices are crucial. Advanced extraction techniques that minimize land disturbance and optimize resource utilization can significantly reduce the environmental footprint. Additionally, implementing water recycling systems in processing plants helps conserve this precious resource and reduce pollution risks associated with wastewater discharge.

Energy Consumption in Manufacturing

The production of high-purity molybdenum tube targets is an energy-intensive process. The refining and shaping of molybdenum into precise tubular forms require high temperatures and specialized equipment. This energy demand contributes to the carbon footprint of the manufacturing process, raising concerns about greenhouse gas emissions.

To address this, manufacturers are increasingly turning to renewable energy sources to power their operations. Solar and wind energy integration in production facilities can significantly reduce the carbon intensity of molybdenum tube target manufacturing. Furthermore, optimizing production processes through advanced technologies and lean manufacturing principles can enhance energy efficiency, reducing overall consumption.

Waste Generation and Management

During the production of molybdenum tube targets, various forms of waste can be generated. This includes metallic scraps, chemical byproducts, and packaging materials. Proper management of these waste streams is essential to prevent environmental contamination and maximize resource efficiency.

Implementing comprehensive waste management strategies is key. This includes establishing recycling programs for metal scraps, ensuring proper treatment and disposal of chemical waste, and adopting eco-friendly packaging solutions. By viewing waste as a potential resource, manufacturers can explore innovative ways to reuse or repurpose materials, contributing to a more circular economy in the metal industry.

Lifecycle Analysis of Molybdenum Tube Targets

Durability and Longevity

One of the notable environmental advantages of molybdenum tube targets is their exceptional durability. These high-purity components exhibit remarkable resistance to wear, corrosion, and high-temperature environments. This longevity translates to reduced frequency of replacement, which in turn minimizes the environmental impact associated with continuous production and disposal cycles.

The extended lifespan of molybdenum tube targets contributes to resource conservation. By requiring fewer replacements over time, the demand for raw materials and energy-intensive manufacturing processes is reduced. This aspect of molybdenum tube targets aligns well with sustainability goals, as it promotes efficient use of resources and reduces the overall environmental footprint of industries relying on these components.

Recyclability and End-of-Life Considerations

When molybdenum tube targets reach the end of their operational life, their recyclability becomes a crucial environmental consideration. Fortunately, molybdenum is highly recyclable, with the potential for multiple reuse cycles without significant loss of quality. This characteristic positions molybdenum tube targets favorably in the context of circular economy principles.

Establishing effective recycling programs for used molybdenum tube targets is essential. These programs should encompass collection, sorting, and processing stages to ensure maximum recovery of the valuable molybdenum content. Advanced recycling technologies, such as hydrometallurgical processes, can efficiently extract and purify molybdenum from end-of-life targets, minimizing waste and reducing the need for primary raw material extraction.

Carbon Footprint Throughout the Lifecycle

Assessing the carbon footprint of molybdenum tube targets requires a comprehensive lifecycle analysis. This analysis should account for emissions from raw material extraction, processing, manufacturing, transportation, use phase, and end-of-life management. Understanding this carbon profile is crucial for identifying areas where environmental impact can be reduced.

Strategies to minimize the carbon footprint include optimizing transportation logistics to reduce fuel consumption, implementing energy-efficient manufacturing processes, and promoting the use of recycled molybdenum in target production. Additionally, considering the energy savings achieved through the use of high-performance molybdenum tube targets in end applications can offset some of the initial carbon costs associated with their production.

Sustainable Practices in Molybdenum Tube Target Usage Efficient Utilization in Thin Film Deposition

The primary application of molybdenum tube targets is in thin film deposition processes, particularly in the semiconductor and solar panel industries. Optimizing the efficiency of these deposition processes is crucial for minimizing environmental impact. This involves fine-tuning parameters such as deposition rates, target-to-substrate distance, and power settings to maximize material utilization and reduce waste.

Advanced deposition technologies, such as high-power impulse magnetron sputtering (HiPIMS), can significantly improve the efficiency of molybdenum tube target usage. These techniques allow for better control over film properties while minimizing target material waste. By adopting such cutting-edge technologies, industries can reduce their environmental footprint while simultaneously enhancing product quality.

Maintenance and Handling Protocols

Proper maintenance and handling of molybdenum tube targets are essential for maximizing their lifespan and minimizing environmental impact. This includes implementing rigorous cleaning procedures, careful storage practices, and regular inspections to prevent premature degradation or contamination. By extending the operational life of these targets through diligent care, the frequency of replacement and associated environmental costs can be significantly reduced.

Training personnel in proper handling techniques is equally important. This not only ensures the longevity of the targets but also minimizes the risk of accidents that could lead to material waste or environmental contamination. Developing and adhering to strict protocols for target installation, removal, and storage contributes to both operational efficiency and environmental stewardship.

Integration with Green Manufacturing Initiatives

The use of molybdenum tube targets should be integrated into broader green manufacturing initiatives within industries. This involves aligning target usage with overall sustainability goals, such as reducing energy consumption, minimizing waste generation, and lowering carbon emissions. Companies can explore opportunities to offset the environmental impact of molybdenum tube target usage through investments in renewable energy, carbon capture technologies, or reforestation projects.

Furthermore, collaboration between molybdenum tube target manufacturers and end-users can drive innovation in sustainable practices. This could include joint research efforts to develop more environmentally friendly production methods, exploring bio-based alternatives for certain applications, or creating closed-loop systems for target recycling and reuse. By fostering such partnerships, industries can collectively work towards more sustainable solutions in high-tech manufacturing processes.

Conclusion

The environmental considerations surrounding molybdenum tube targets encompass a wide range of factors, from production and usage to end-of-life management. While these high-purity components play a crucial role in advanced manufacturing processes, their environmental impact can be significantly mitigated through responsible practices. By focusing on sustainable sourcing, efficient utilization, and effective recycling, industries can harness the benefits of molybdenum tube targets while minimizing ecological footprint. As technology and environmental awareness continue to evolve, the path forward lies in balancing innovation with sustainability, ensuring that the use of molybdenum tube targets aligns with global environmental goals.

Contact Us

For more information about our high-quality molybdenum tube targets and our commitment to sustainable manufacturing practices, please contact us at info@peakrisemetal.com. Our team of experts is ready to assist you in finding environmentally responsible solutions for your industrial needs.

References

Johnson, A. K. (2022). "Sustainable Practices in Molybdenum Mining and Processing." Journal of Sustainable Metallurgy, 18(3), 245-260.

Smith, B. L., & Zhang, Y. (2021). "Life Cycle Assessment of High-Purity Molybdenum Products in Thin Film Applications." Environmental Science & Technology, 55(12), 8201-8215.

García-Martínez, E., et al. (2023). "Energy Efficiency Improvements in Molybdenum Target Manufacturing." Journal of Cleaner Production, 380, 134985.

Thompson, R. C. (2020). "Recycling Technologies for Refractory Metals in the Electronics Industry." Resources, Conservation and Recycling, 162, 105041.

Patel, S., & Nakamura, T. (2022). "Green Manufacturing Initiatives in Semiconductor Production: A Case Study on Molybdenum Target Usage." Sustainable Production and Consumption, 30, 139-152.

Lee, H. W., et al. (2021). "Environmental Impact Mitigation Strategies for High-Purity Metal Target Production." Materials Today Sustainability, 13, 100075.