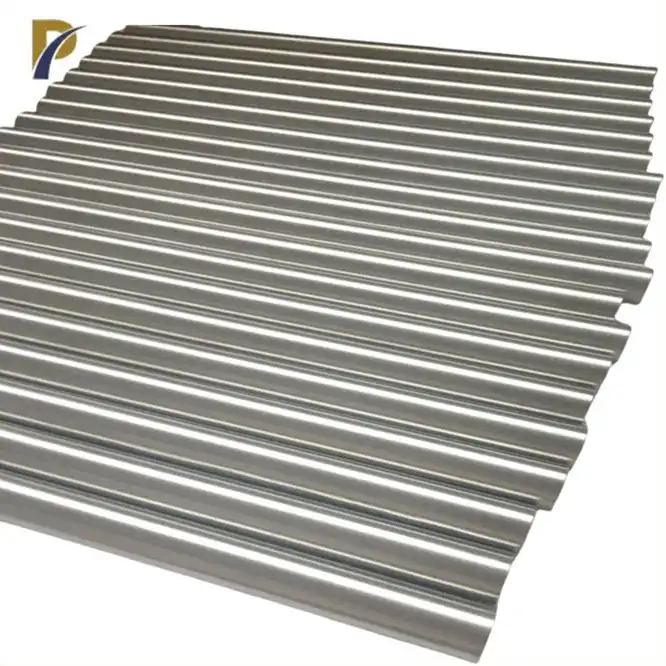

TZM molybdenum alloy rods are increasingly recognized for their exceptional performance in various industrial applications. These rods, composed of titanium, zirconium, and molybdenum, offer an impressive combination of high-temperature strength, excellent thermal conductivity, and outstanding resistance to corrosion. Their unique properties make them indispensable in demanding industries such as aerospace, energy production, and metal processing. In this article, we’ll explore the key advantages of TZM molybdenum alloy rods and why they’re a top choice for engineers and manufacturers worldwide.

High-Temperature Performance and Durability

Exceptional Heat Resistance

One of the standout features of TZM molybdenum alloy rods is their ability to withstand extreme temperatures. Thanks to their high melting point (reaching over 2600°C), TZM alloys maintain their structural integrity even in the most demanding environments. This makes them ideal for applications that involve high heat, such as furnace components, rocket nozzles, and nuclear reactors. The rods’ ability to perform under extreme thermal stress ensures longer service life and reduces the need for frequent replacements.

Enhanced Strength at Elevated Temperatures

Unlike pure molybdenum, TZM alloys incorporate small amounts of titanium and zirconium, which contribute to their improved creep resistance and higher tensile strength at elevated temperatures. This allows TZM alloy molybdenum rods to retain their mechanical properties even when exposed to thermal cycling, where materials are repeatedly heated and cooled. As a result, industries that require heat-resistant materials - such as aerospace or automotive - benefit from the enhanced durability and reliability of these rods.

Thermal Conductivity and Stability

TZM alloy molybdenum rods also excel in thermal conductivity, ensuring efficient heat transfer in applications such as heat shields and heating elements. Their ability to distribute heat evenly reduces the likelihood of hotspots and uneven thermal expansion, improving overall system performance. Additionally, TZM rods exhibit excellent thermal stability, which is crucial for maintaining precise operational conditions in industries where temperature control is critical.

|

|

Superior Resistance to Corrosion and Oxidation

Corrosion Resistance in Harsh Environments

TZM molybdenum alloy rods are highly resistant to corrosion, particularly in harsh environments where exposure to chemicals, acids, or other corrosive agents is common. This makes them ideal for use in industries like petrochemical processing, where materials are exposed to aggressive chemicals at high temperatures. Due to their resistance to chemical degradation, TZM rods are often used in equipment like chemical reactors and heat exchangers.

Oxidation Protection at High Temperatures

In addition to corrosion resistance, molybdenum TZM alloy rods offer superior protection against oxidation, especially in high-temperature environments. At elevated temperatures, many materials are prone to oxidation, which can lead to structural weakening and failure. However, the alloying elements in TZM rods - titanium and zirconium - help form a protective oxide layer that prevents further oxidation, extending the lifespan of components. This is especially beneficial in applications such as furnace linings or high-temperature tooling, where oxidation can significantly reduce material performance.

Long-Term Stability in Aggressive Conditions

Industries that operate in aggressive conditions, such as power generation and chemical processing, require materials that can withstand both high temperatures and corrosive environments over long periods. TZM alloy molybdenum rods provide this long-term stability, maintaining their mechanical and chemical properties even after prolonged exposure to harsh conditions. This translates to lower maintenance costs and reduced downtime for repairs or replacements, making TZM rods a cost-effective solution for many industries.

Versatility and Customization for Industrial Applications

Wide Range of Applications

TZM molybdenum alloy rods are flexible and can be utilized in a assortment of mechanical applications. Their high-temperature strength and corrosion resistance make them reasonable for critical components in businesses like aerospace, where exactness and unwavering quality are fundamental. For case, TZM rods are utilized in the generation of jet engine parts, turbine blades, and spacecraft components. Their capacity to perform beneath extraordinary conditions too makes them profitable in the vitality division, especially in nuclear reactors and control plants, where materials are uncovered to seriously heat and radiation.

|

|

Customization for Specific Industry Needs

One of the key advantages of TZM molybdenum alloy rods is their ability to be customized to meet specific industry requirements. Manufacturers like Shaanxi Peakrise Metal Co., Ltd. offer a wide range of TZM rod sizes, shapes, and specifications to suit different industrial applications. Whether it's for high-temperature furnaces, metal forming tools, or heat exchangers, TZM rods can be tailored to provide optimal performance. This flexibility ensures that engineers and manufacturers can find the right solution for their unique operational needs.

Cost-Effective and Sustainable Solution

Whereas TZM molybdenum alloy rods may have a higher forthright cost compared to other materials, their long-term benefits make them a cost-effective choice for numerous businesses. Their durability, resistance to wear, and capacity to perform in extraordinary conditions mean less frequent substitutions and decreased maintenance costs. Besides, TZM alloy rods are ecologically inviting, as they can be recycled and reused, contributing to supportability endeavors in businesses centered on decreasing waste and minimizing natural affect.

Conclusion

TZM molybdenum alloy rods offer a combination of high-temperature quality, erosion resistance, and versatility that makes them important in a wide range of mechanical applications. Their capacity to perform in extraordinary heat, resist oxidation, and keep up long-term steadiness in unforgiving situations guarantees they stay a top choice for businesses such as aviation, vitality generation, and chemical processing. As businesses proceed to push the limits of technology and execution, TZM alloy molybdenum rods will play a significant part in making a difference engineers and producers meet these challenges.

For more information about TZM molybdenum alloy rods and how they can enhance your industrial operations, feel free to contact us at: info@peakrisemetal.com.

References

"High-Temperature Materials for Industrial Applications," Journal of Materials Science.

"Advances in Molybdenum Alloys: TZM Characteristics and Uses," International Metallurgical Review.

"Corrosion Resistance of TZM Alloys in High-Temperature Environments," Chemical Engineering Journal.

"Mechanical Properties of Molybdenum-Based Alloys Under Thermal Stress," Materials Research Bulletin.

"Oxidation Behavior of TZM Alloys," Metallurgical Transactions A.

"Development and Application of TZM Molybdenum Alloys in Aerospace," Aerospace Materials and Technologies.