Thermal Conductivity and Heat Transfer Properties of Molybdenum TZM Alloy

Understanding Thermal Conductivity in TZM Alloy

Molybdenum TZM alloy boasts an impressive thermal conductivity, a crucial property that determines its ability to conduct heat efficiently. This characteristic is particularly valuable in applications where rapid heat dissipation is essential. The alloy's thermal conductivity remains relatively stable across a wide temperature range, making it suitable for use in both cryogenic and high-temperature environments. Compared to other refractory metals, TZM alloy exhibits superior heat transfer capabilities, allowing for more uniform temperature distribution in critical components.

Heat Transfer Mechanisms in TZM Alloy

The heat transfer properties of molybdenum TZM alloy are influenced by its unique microstructure and composition. The addition of titanium and zirconium to the molybdenum base enhances the alloy's thermal stability and resistance to grain growth at elevated temperatures. This refinement in grain structure contributes to improved heat distribution throughout the material. Furthermore, the presence of these alloying elements creates a solid solution strengthening effect, which helps maintain the alloy's thermal properties even under prolonged exposure to high temperatures.

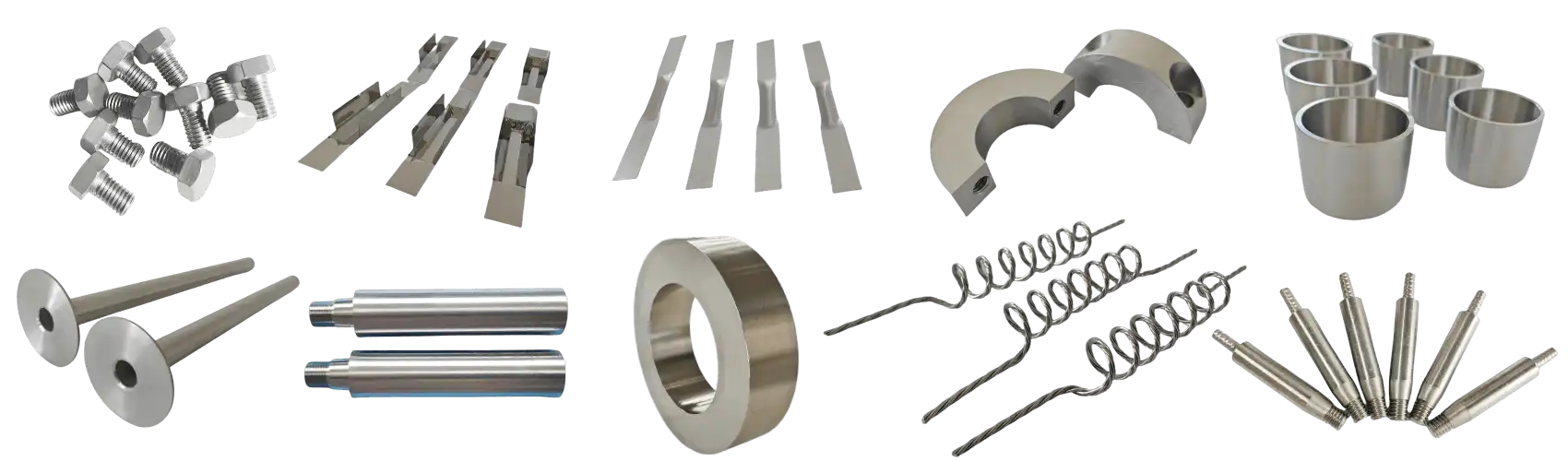

Applications Leveraging TZM's Thermal Conductivity

The exceptional thermal conductivity of molybdenum TZM alloy finds applications in various high-tech industries. In semiconductor manufacturing, TZM components are used in furnace systems where precise temperature control is paramount. The aerospace sector utilizes TZM alloy in rocket nozzles and heat shields, capitalizing on its ability to rapidly dissipate heat and maintain structural integrity under extreme conditions. Additionally, the nuclear industry employs TZM alloy in reactor components, benefiting from its excellent heat transfer properties and resistance to radiation-induced swelling.

|

|

Temperature Resistance and Stability of Molybdenum TZM Alloy

High-Temperature Strength Retention

One of the most remarkable features of molybdenum TZM alloy is its ability to retain strength at elevated temperatures. Unlike many conventional materials that soften or lose structural integrity when exposed to high heat, TZM alloy maintains its mechanical properties well above 1000°C (1832°F). This temperature resistance is attributed to its high melting point, which exceeds 2600°C (4712°F), and the presence of titanium and zirconium carbides that form during processing. These carbides act as barriers to dislocation movement, preserving the alloy's strength even in extreme thermal environments.

Creep Resistance at Elevated Temperatures

Molybdenum TZM alloy exhibits exceptional creep resistance, a critical property for materials subjected to prolonged stress at high temperatures. Creep, the tendency of a material to deform slowly over time under constant load, is significantly mitigated in TZM alloy due to its refined grain structure and dispersion-strengthened microstructure. This resistance to creep deformation ensures that components made from TZM alloy maintain their dimensional stability and structural integrity in long-term, high-temperature applications, such as industrial furnaces and aerospace propulsion systems.

Thermal Shock Resistance

The ability to withstand rapid temperature changes without failure is another hallmark of molybdenum TZM alloy. Its excellent thermal shock resistance stems from a combination of high thermal conductivity and low thermal expansion coefficient. This property is particularly valuable in applications where materials are subjected to cyclic heating and cooling, such as in die-casting molds or plasma-facing components in fusion reactors. TZM alloy's resilience against thermal fatigue extends the operational lifespan of critical components, reducing maintenance requirements and improving overall system reliability.

Thermal Expansion Characteristics of Molybdenum TZM Alloy

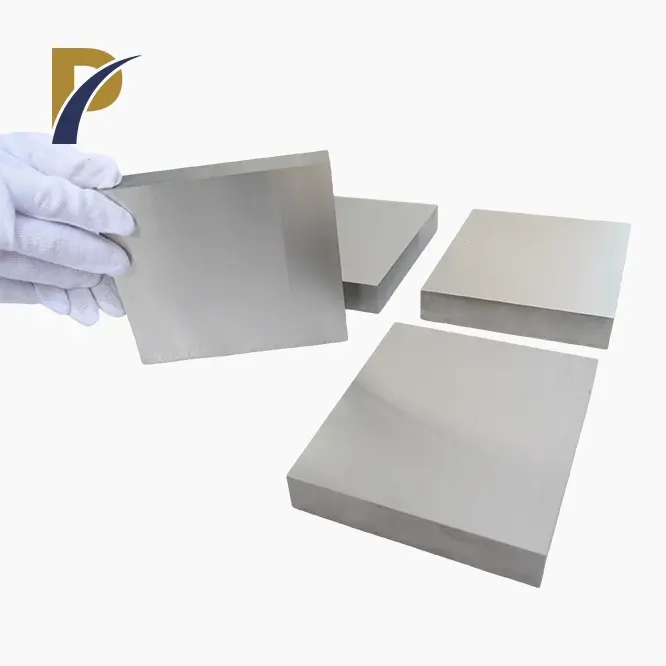

Low Coefficient of Thermal Expansion

Molybdenum TZM alloy is characterized by its remarkably low coefficient of thermal expansion (CTE), a property that sets it apart from many other engineering materials. This low CTE translates to minimal dimensional changes when the alloy is subjected to temperature fluctuations. In precision engineering applications, such as optical systems or high-precision measurement instruments, TZM alloy's dimensional stability across a wide temperature range is invaluable. The alloy's resistance to thermal expansion and contraction helps maintain tight tolerances and ensures consistent performance in thermally dynamic environments.

Comparison with Other High-Temperature Materials

When compared to other high-temperature materials, molybdenum TZM alloy often outperforms in terms of thermal expansion characteristics. For instance, while superalloys based on nickel or cobalt exhibit higher CTEs, TZM alloy maintains its dimensional integrity more effectively at elevated temperatures. This comparative advantage makes TZM alloy an attractive choice for applications where thermal expansion mismatch could lead to mechanical stress or failure, such as in metal-ceramic joints or high-temperature sealing systems.

Implications for Design and Engineering

The unique thermal expansion properties of molybdenum TZM alloy have significant implications for design and engineering practices. Engineers can leverage TZM's low CTE to create components that maintain precise geometries and clearances under varying thermal conditions. This characteristic is particularly beneficial in the design of high-temperature machinery, where thermal expansion can lead to efficiency losses or mechanical failures. By incorporating TZM alloy into critical components, designers can enhance the overall thermal management and reliability of complex systems operating in extreme temperature environments.

Conclusion

Molybdenum TZM alloy stands out as a remarkable material with exceptional thermal properties that make it indispensable in high-temperature applications. Its superior thermal conductivity, outstanding temperature resistance, and low thermal expansion coefficient combine to create a versatile alloy capable of withstanding the most demanding thermal environments. From aerospace to nuclear energy, TZM alloy continues to push the boundaries of what's possible in material science, enabling innovations in industries where extreme heat is a constant challenge. As research and development in refractory metals progress, molybdenum TZM alloy remains at the forefront, promising even greater advancements in thermal management and high-temperature material applications.

Contact Us

For more information about molybdenum TZM alloy and its applications, please contact Shaanxi Peakrise Metal Co., Ltd. at info@peakrisemetal.com. Our team of experts is ready to assist you in finding the perfect solution for your high-temperature material needs.