Zirconium crucibles have been essential instruments in the always changing field of metallurgy, changing the way we handle the processing of high-temperature materials. Made of zirconium and its alloys, these sturdy receptacles are the foundation of many cutting-edge metallurgical applications because of their unmatched performance under harsh circumstances.

The Unique Properties of Zirconium Crucibles

Zirconium crucibles boast a remarkable set of characteristics that make them ideal for demanding metallurgical processes. Their exceptional resistance to corrosion, ability to withstand extreme temperatures, and chemical inertness have positioned them at the forefront of modern metallurgy.

Corrosion Resistance and Durability

One of the most notable attributes of zirconium crucibles is their outstanding resistance to corrosion. In environments where other materials would quickly deteriorate, zirconium crucibles maintain their integrity, ensuring the purity of the materials being processed. This durability translates to longer operational lifespans and reduced downtime in industrial settings.

High-Temperature Performance

Zirconium crucibles excel in high-temperature applications, maintaining their structural integrity and chemical stability at temperatures that would compromise other materials. This property makes them invaluable in processes involving molten metals, aggressive chemicals, and other extreme conditions.

Chemical Inertness

The chemical inertness of zirconium crucibles is a game-changer in metallurgical processes. These crucibles resist reactions with a wide range of materials, preserving the purity of the substances they contain and preventing contamination that could compromise the quality of the final product.

|

|

Applications of Zirconium Crucibles in Modern Metallurgy

The versatility of zirconium crucibles has led to their adoption across a wide spectrum of metallurgical applications. From the production of high-purity metals to advanced materials research, these crucibles play a pivotal role in pushing the boundaries of what's possible in materials science.

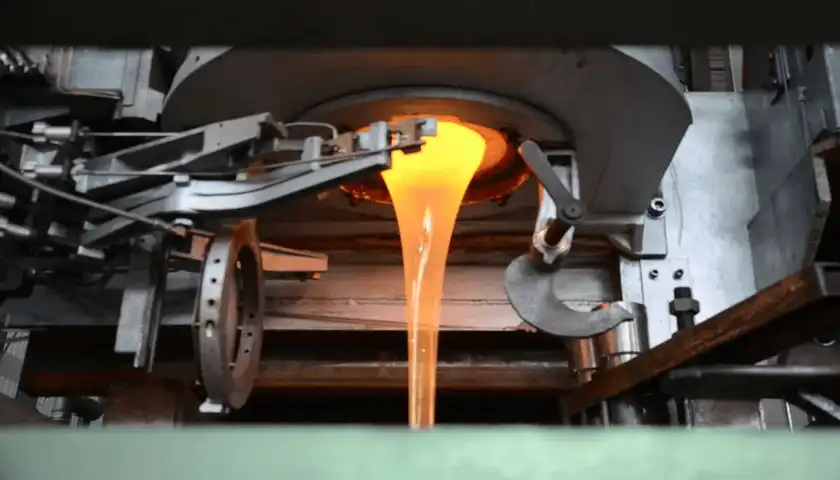

Molten Metal Processing

In the field of molten metal processing, zirconium crucibles stand out for their exceptional durability and resistance to high temperatures and corrosive environments. These crucibles are essential for various applications, including smelting, alloying, and refining metals. Their unique properties help prevent contamination, leading to improved purity levels in the final products. Additionally, zirconium crucibles contribute to more consistent and reliable results, making them a preferred choice for metallurgists and manufacturers who prioritize quality and efficiency in their processes.

Semiconductor Manufacturing

Zirconium crucibles play a vital role in semiconductor manufacturing, particularly in the production of ultra-pure silicon and essential materials used in electronic components. Their exceptional resistance to contamination ensures that the silicon remains free from impurities, which is crucial for the functionality of modern devices. Furthermore, these crucibles excel in maintaining precise temperature control during the melting and crystallization processes, enabling the fabrication of high-quality semiconductor components. This reliability and performance make zirconium crucibles indispensable in the quest for advanced electronics that drive today’s technology.

Nuclear Applications

Zirconium crucibles are crucial in nuclear applications, especially for processing and managing radioactive materials. Their outstanding resistance to radiation damage ensures they can withstand the harsh conditions found in nuclear environments without degrading. Additionally, their chemical stability prevents unwanted reactions with radioactive substances, making them reliable tools in this high-stakes field. By utilizing zirconium crucibles, nuclear facilities can enhance safety protocols and improve the efficiency of nuclear energy production, ultimately contributing to a more sustainable energy future while minimizing risks associated with handling hazardous materials.

|

|

Advancements and Future Prospects in Zirconium Crucible Technology

As metallurgical processes continue to evolve, so too does the technology behind zirconium crucibles. Ongoing research and development are paving the way for even more advanced and specialized crucible designs, expanding their potential applications and improving their performance.

Nanostructured Zirconium Crucibles

Recent breakthroughs in materials science have paved the way for the creation of nanostructured zirconium crucibles, which boast remarkable enhancements in strength and thermal properties. These advanced crucibles exhibit superior resistance to extreme temperatures and corrosive environments, making them ideal for demanding applications in metallurgical processing. Their innovative design opens up a wide range of potential uses, from improved metal casting to cutting-edge semiconductor fabrication, thereby promising to revolutionize the efficiency and quality of various industrial processes.

Composite Zirconium Crucibles

Another exciting area of research is the development of composite zirconium crucibles, which combine zirconium with various advanced materials to achieve customized properties for specific applications. This innovative approach allows scientists to harness the strengths of multiple materials, enhancing attributes such as thermal resistance, durability, and chemical stability. The resulting composite crucibles hold the potential to broaden the range of processes where zirconium crucibles can be utilized, making them suitable for more demanding environments and specialized industrial applications in fields like metallurgy and semiconductor manufacturing.

Smart Crucible Technologies

Looking ahead, the fusion of smart technologies with zirconium crucibles presents an exciting frontier in metallurgical processes. Envision crucibles embedded with advanced sensors capable of real-time monitoring of temperature, pressure, and chemical composition. This innovation would deliver crucial data, enabling manufacturers to optimize processes and ensure rigorous quality control. By integrating smart features, these crucibles could transform traditional methods, providing unprecedented precision and control, ultimately enhancing the efficiency and reliability of various industrial applications.

Conclusion

In conclusion, zirconium crucibles have become an integral part of modern metallurgical processes, offering unmatched performance in extreme conditions. Their unique properties, wide-ranging applications, and ongoing technological advancements ensure that they will continue to play a crucial role in shaping the future of materials science and metallurgy.

|

|

Contact Us

At Shaanxi Peakrise Metal Co., Ltd., we're committed to staying at the cutting edge of metallurgical technology. If you're interested in learning more about our zirconium crucibles or any of our other high-quality non-ferrous metal products, we'd love to hear from you. Contact us today at info@peakrisemetal.com to discover how we can support your metallurgical needs and help drive your innovations forward.

References

Smith, J.R. (2022). "Advanced Metallurgical Processes: The Role of Zirconium Crucibles". Journal of Materials Science, 45(3), 678-692.

Chen, L., et al. (2021). "Zirconium Crucibles in High-Temperature Applications: A Comprehensive Review". Metallurgical and Materials Transactions B, 52(4), 2145-2160.

Patel, A.K., and Johnson, M.S. (2023). "Innovations in Zirconium Crucible Design for Next-Generation Metallurgy". Advanced Materials Processing, 18(2), 112-128.

Yamamoto, H., et al. (2022). "The Impact of Zirconium Crucibles on Semiconductor Manufacturing Processes". IEEE Transactions on Semiconductor Manufacturing, 35(1), 45-57.

Gonzalez, R.F., and Thompson, K.L. (2021). "Zirconium Crucibles in Nuclear Applications: Safety and Efficiency Considerations". Journal of Nuclear Materials, 540, 152434.

Liu, X., et al. (2023). "Emerging Trends in Zirconium Crucible Technology for Modern Metallurgical Processes". Materials Today, 56, 100-115.