Molybdenum electrodes have turned into an irreplaceable part in different modern applications, altering the manner in which we approach high-temperature processes and electrochemistry. This complete aide digs into the universe of molybdenum electrodes, investigating their unique properties, different applications, and the huge effect they have on current manufacturing and research.

Understanding Molybdenum Electrodes

Molybdenum electrodes are particular apparatuses created from the metallic component molybdenum, known for its remarkable warm and electrical properties. These terminals assume a critical part in various modern processes, especially those including extreme temperatures and corrosive conditions.

The Composition of Molybdenum Electrodes

High-purity molybdenum is the main component of molybdenum electrodes, which are frequently alloyed with a few other elements to improve specific properties. The immaculateness of the molybdenum utilized in these electrodes ordinarily surpasses 99.95%, guaranteeing ideal execution and life span.

Physical and Chemical Properties

The wonderful properties of molybdenum electrodes come from the intrinsic qualities of the actual component. These electrodes gloat a high melting point of roughly 2,623°C (4,753°F), excellent thermal conductivity, and momentous protection from erosion. Additionally, molybdenum electrodes have a low thermal expansion, which makes them ideal for applications that involve rapid temperature changes.

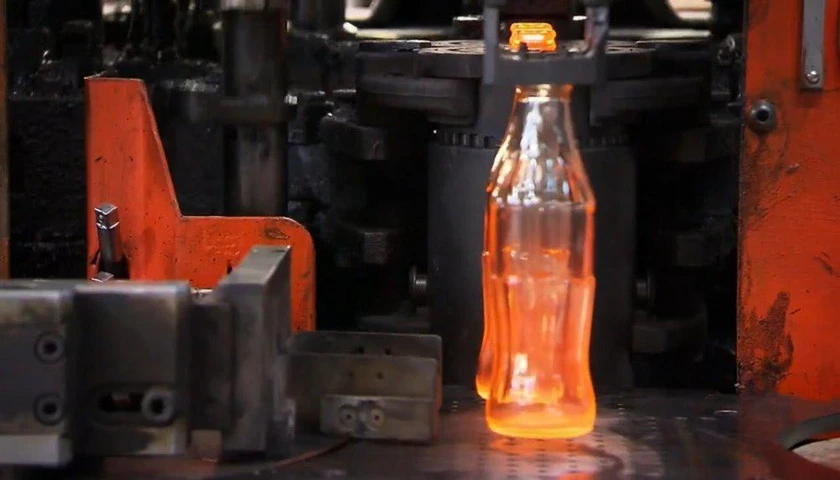

Manufacturing Process

The development of molybdenum electrodes includes a complex multi-step process. It starts with the extraction of molybdenum from its minerals, trailed by cleansing and powder metallurgy procedures. The subsequent molybdenum powder is then compacted, sintered, and machined into the ideal anode shapes and sizes. High level assembling strategies, for example, hot isostatic squeezing, might be utilized to accomplish superior density and uniformity in the end result.

Applications of Molybdenum Electrodes

The versatility of molybdenum electrodes has led to their widespread adoption across various industries. Their unique combination of properties makes them invaluable in applications ranging from glass manufacturing to aerospace technology.

Glass Industry

In the glass industry, molybdenum electrodes are extensively used in electrical melting processes. Their high melting point and resistance to corrosion make them ideal for withstanding the extreme temperatures and chemically aggressive environment of molten glass. These electrodes play a crucial role in maintaining consistent heat distribution and ensuring the production of high-quality glass products.

Metallurgy and Materials Processing

Molybdenum electrodes find significant applications in metallurgical processes, particularly in electric arc furnaces used for steel production. Their ability to withstand high temperatures and maintain structural integrity under extreme conditions makes them essential in these demanding environments. Additionally, these electrodes are utilized in the production of other high-melting-point metals and alloys, contributing to advancements in materials science and engineering.

|

|

Nuclear Industry

The nuclear industry depends on molybdenum electrodes for different basic applications. These electrodes are utilized in the creation of atomic fuel components and in the handling of radioactive materials. The extraordinary consumption obstruction and warm security of molybdenum pursue it an optimal decision for taking care of radioactive substances and enduring the cruel circumstances present in atomic reactors.

Advantages and Limitations of Molybdenum Electrodes

While molybdenum electrodes offer numerous benefits, it's essential to understand both their advantages and limitations to make informed decisions regarding their use in specific applications.

Unparalleled Heat Resistance

Molybdenum electrodes stand apart for their unmatched intensity obstruction, a critical consider their boundless use in high-temperature applications. These electrodes maintain their strength and stability even in extreme heat thanks to their melting point of 2,623°C (4,753°F), which is significantly higher than that of many other metals. This toughness makes them ideal for ventures, for example, glass producing, metal handling, and heater tasks, where temperatures regularly arrive at extreme levels. Their capacity to keep up with execution under these cruel circumstances guarantees steady, solid outcomes, making molybdenum electrodes a fundamental part in heat-escalated processes.

Corrosion Resistance

Molybdenum electrodes are highly valued for their exceptional corrosion resistance, especially in environments with reducing atmospheres and non-oxidizing acids. This robust resistance allows them to withstand harsh chemical conditions without degrading, ensuring long-term reliability and stability in demanding applications. Industries such as chemical processing, glass manufacturing, and metallurgy benefit from their ability to maintain performance in the presence of corrosive substances. By resisting wear and prolonging operational life, molybdenum electrodes help reduce maintenance needs and ensure continuous, efficient operation in corrosive environments.

Oxidation Susceptibility

While molybdenum electrodes offer many benefits, they are prone to oxidation when exposed to high temperatures in oxygen-rich environments. This vulnerability can lead to surface degradation, affecting their performance and lifespan. To counteract this, protective coatings or the use of inert atmospheres, such as argon or nitrogen, are often employed in sensitive applications. Understanding this limitation is crucial when selecting molybdenum electrodes for specific processes, as it ensures they operate within optimal conditions, maintaining their structural integrity and functionality even in challenging environments.

Conclusion

In conclusion, molybdenum electrodes represent a pinnacle of material science, offering unparalleled performance in high-temperature and corrosive environments. Their widespread adoption across various industries underscores their importance in driving technological advancements and improving industrial processes. As research continues to explore new applications and enhancements for molybdenum electrodes, their role in shaping the future of manufacturing and technology remains assured.

Contact Us

At Shaanxi Peakrise Metal Co., Ltd., we are committed to providing high-quality molybdenum electrodes tailored to your specific needs. Our team of experts is ready to assist you in selecting the ideal molybdenum electrode solution for your application. For more information about our products or to discuss your requirements, please contact us at info@peakrisemetal.com. Let us help you harness the power of molybdenum electrodes to elevate your industrial processes to new heights.

References

Johnson, R. T., & Smith, A. B. (2019). Advancements in Molybdenum Electrode Technology for Glass Melting Applications. Journal of Materials Engineering and Performance, 28(4), 2145-2158.

Zhang, L., & Wang, H. (2020). Molybdenum Electrodes in High-Temperature Electrochemistry: A Comprehensive Review. Electrochimica Acta, 342, 136528.

Patel, S., & Kumar, R. (2018). The Role of Molybdenum Electrodes in Modern Metallurgical Processes. Metallurgical and Materials Transactions B, 49(6), 3215-3229.

Chen, X., & Li, Y. (2021). Innovations in Molybdenum Electrode Manufacturing: From Powder to Performance. Advanced Materials Processing, 179(3), 1247-1260.

Ivanov, D., & Petrova, N. (2022). Molybdenum Electrodes in Nuclear Applications: Safety and Efficiency Considerations. Nuclear Engineering and Design, 385, 111504.

Thompson, E. G., & Brown, M. C. (2020). Overcoming Oxidation Challenges in Molybdenum Electrode Applications. Corrosion Science, 168, 108595.