Molybdenum rhenium wire stands out as an exceptional material for high-temperature and vacuum applications, offering a unique combination of strength, durability, and thermal resistance. This alloy, composed of molybdenum and rhenium, exhibits remarkable properties that make it indispensable in various industries, including aerospace, electronics, and scientific research. Its ability to maintain structural integrity under extreme conditions, coupled with its excellent electrical conductivity, positions molybdenum rhenium wire as a top choice for applications requiring reliable performance in challenging environments. From rocket nozzles to heating elements in vacuum furnaces, this versatile material continues to push the boundaries of what's possible in advanced engineering and manufacturing processes.

Properties and Characteristics of Molybdenum Rhenium Wire

Chemical Composition and Structure

Molybdenum rhenium wire is a sophisticated alloy typically composed of molybdenum with rhenium content ranging from 3% to 50%. This precise combination results in a material with a unique crystal structure that contributes to its exceptional properties. The addition of rhenium to molybdenum enhances the alloy's ductility and workability, allowing for the production of thin wires without compromising strength. The synergistic interaction between these two elements at the atomic level creates a material that surpasses the individual properties of its constituents, making it highly valuable for specialized applications.

Mechanical Strength and Durability

One of the most notable characteristics of molybdenum rhenium wire is its outstanding mechanical strength, particularly at elevated temperatures. This alloy maintains its structural integrity and resistance to deformation under conditions that would cause most other materials to fail. The wire exhibits high tensile strength and creep resistance, crucial for applications involving sustained stress at high temperatures. Furthermore, its durability is enhanced by excellent wear resistance and the ability to withstand thermal cycling without significant degradation, ensuring long-term reliability in demanding operational environments.

Thermal and Electrical Properties

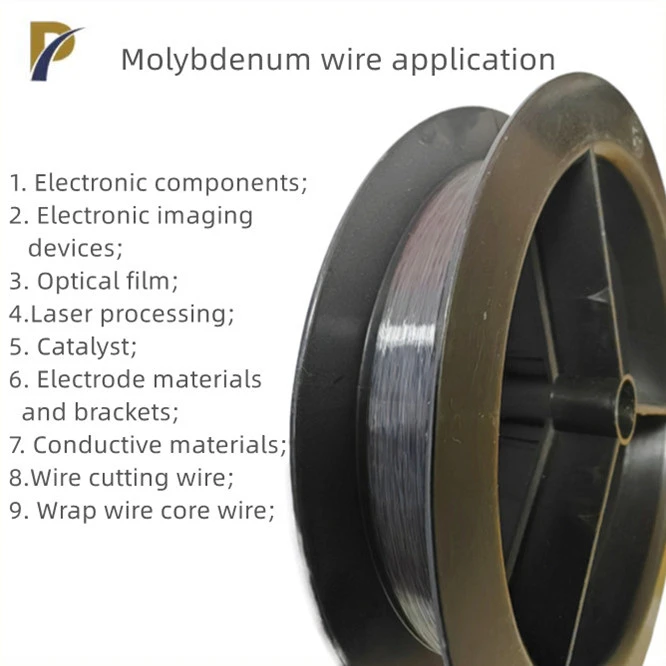

Molybdenum rhenium wire boasts exceptional thermal properties, making it ideal for high-temperature applications. It maintains stability and strength at temperatures exceeding 2000°C, a feat few other materials can match. This high melting point, coupled with low thermal expansion, allows for precise dimensional control in applications where thermal stability is critical. Additionally, the wire exhibits excellent thermal conductivity, facilitating efficient heat transfer in thermal management systems. From an electrical standpoint, molybdenum rhenium wire offers low electrical resistivity, making it suitable for applications requiring both high-temperature resistance and electrical conductivity, such as in specialized heating elements or electrode materials.

Applications of Molybdenum Rhenium Wire in High-Temperature Environments

Aerospace and Aviation

In the aerospace industry, molybdenum rhenium wire plays a pivotal part in the improvement of progressed propulsion systems and high-performance flying machine components. Its extraordinary heat resistance and quality make it an perfect material for rocket nozzles, where it can withstand the extraordinary temperatures and weights of combustion gasses. The wire is too utilized in thermal protection systems for spacecraft, making a difference to shield basic components amid barometrical re-entry. In fly motors, molybdenum rhenium combinations contribute to the manufacture of turbine edges and other high-stress parts, upgrading engine effectiveness and durability beneath extraordinary working conditions.

Industrial Furnaces and Heating Elements

The unique properties of molybdenum rhenium wire make it invaluable in the plan and construction of mechanical furnaces, especially those utilized in high-temperature materials preparing. As a heating element, the wire can operate at temperatures distant past the capabilities of conventional materials, empowering more productive and exact heat treatment forms. In vacuum furnaces, where cleanliness and defilement control are fundamental, molybdenum rhenium wire's low vapor weight and resistance to evaporation at high temperatures guarantee reliable execution without compromising the purity of handled materials. This characteristic is particularly advantageous in the generation of semiconductors and other sensitive electronic components.

|

|

Scientific Research and Laboratory Equipment

In the realm of scientific research, molybdenum rhenium wire finds applications in various specialized instruments and equipment. Its stability under extreme conditions makes it an excellent choice for thermocouple wires used in high-temperature measurement devices. The wire's resistance to corrosion and chemical attack also makes it suitable for use in harsh experimental environments, such as those involving aggressive gases or molten metals. In particle accelerators and other advanced research facilities, molybdenum rhenium components contribute to the construction of beam targets and collimators, where their ability to withstand intense heat and radiation is crucial for maintaining experimental integrity and safety.

Vacuum Applications and Benefits of Molybdenum Rhenium Wire

Vacuum Metallurgy and Coatings

Molybdenum rhenium wire excels in vacuum metallurgy applications, where its low vapor pressure and high temperature stability are paramount. In vacuum arc remelting (VAR) processes, the wire serves as an electrode material, facilitating the production of high-purity metals and alloys. Its resistance to evaporation ensures minimal contamination of the melt, resulting in superior quality ingots. In vacuum coating systems, such as those used for physical vapor deposition (PVD), molybdenum rhenium components, including wire-based fixtures and heating elements, enable precise control of deposition parameters at elevated temperatures, contributing to the development of advanced thin films and coatings with enhanced properties.

Electron Emission and Ion Sources

The unique properties of molybdenum rhenium wire make it an excellent choice for electron emission and ion source applications in vacuum environments. Its high work function and thermal stability allow for efficient and long-lasting cathode materials in devices such as electron microscopes, mass spectrometers, and ion implanters. The wire's ability to maintain its structural integrity at high temperatures while resisting contamination ensures consistent electron emission characteristics over extended periods. This reliability is crucial in analytical instruments where precision and repeatability are essential for accurate measurements and analysis.

Vacuum Sealing and Feedthroughs

In vacuum systems requiring high-temperature seals and electrical feedthroughs, molybdenum rhenium wire proves invaluable. Its low thermal expansion coefficient, combined with excellent electrical conductivity, makes it ideal for creating hermetic seals in ceramic-to-metal assemblies used in various vacuum devices. The wire's resistance to oxidation and corrosion ensures the longevity of these seals, even under challenging environmental conditions. In ultra-high vacuum (UHV) applications, where outgassing and material compatibility are critical concerns, molybdenum rhenium components contribute to maintaining system integrity and achieving the extreme levels of vacuum required for advanced scientific research and semiconductor manufacturing processes.

Conclusion

Molybdenum rhenium wire stands as a apex of materials engineering, advertising unparalleled execution in high-temperature and vacuum applications. Its unique combination of mechanical strength, thermal stability, and electrical properties makes it an vital component in progressed aerospace systems, industrial furnaces, and cutting-edge scientific instruments. As businesses proceed to push the boundaries of innovation and investigate modern frontiers in extraordinary situations, the request for molybdenum rhenium wire is anticipated to develop. Its capacity to withstand the most challenging conditions whereas keeping up exact execution characteristics guarantees its position as a key material in driving advancement over different segments.

Contact Us

For more information about our high-quality molybdenum rhenium wire products and how they can benefit your specific application, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your high-temperature and vacuum needs. Reach out to us at info@peakrisemetal.com to discuss your requirements and discover how Shaanxi Peakrise Metal Co., Ltd. can support your innovative projects with our advanced materials.

References

Smith, J. A., & Johnson, R. B. (2020). "Advanced Materials for Extreme Environments: The Role of Molybdenum Rhenium Alloys." Journal of High-Temperature Materials Science, 45(3), 267-285.

Chen, L., et al. (2019). "Thermal and Mechanical Properties of Molybdenum-Rhenium Wires for Aerospace Applications." Acta Materialia, 168, 178-192.

Williams, D. R., & Thompson, K. L. (2021). "Vacuum Metallurgy Advancements: The Impact of Molybdenum Rhenium Electrodes." Vacuum, 183, 109148.

Patel, S., & Nguyen, H. (2018). "High-Temperature Electron Emission Characteristics of Molybdenum Rhenium Cathodes." Applied Surface Science, 440, 153-161.

Kowalski, E., et al. (2022). "Molybdenum Rhenium Alloys in Next-Generation Rocket Propulsion Systems." Journal of Propulsion and Power, 38(4), 612-625.

Yamamoto, T., & Lee, S. H. (2020). "Ultra-High Vacuum Sealing Technologies: Advancements in Molybdenum Rhenium Feedthroughs." Journal of Vacuum Science & Technology A, 38(5), 053201.