Tungsten crucibles play a pivotal role in advancing the semiconductor and solar industries, serving as indispensable tools in high-temperature manufacturing processes. These crucibles, known for their exceptional heat resistance and durability, enable the production of ultra-pure silicon wafers and solar cells. By withstanding extreme temperatures and maintaining chemical inertness, tungsten crucibles facilitate the precise melting and crystallization of semiconductor materials, ensuring the high-quality components essential for modern electronics and renewable energy technologies. Their unique properties make them irreplaceable in critical processes such as crystal growth, vapor deposition, and thermal treatment, directly contributing to the efficiency and reliability of semiconductors and solar panels.

The Role of Tungsten Crucibles in Semiconductor Manufacturing

Silicon Crystal Growth Process

In the semiconductor industry, tungsten crucibles are fundamental to the Czochralski process, a method used to produce single crystal silicon. The crucible's high melting point (3422°C) and low vapor pressure at elevated temperatures make it ideal for containing molten silicon without contamination. As the silicon ingot is slowly pulled from the melt, the tungsten crucible maintains a stable thermal environment, crucial for growing defect-free crystals that form the basis of semiconductor wafers.

Chemical Vapor Deposition (CVD)

Tungsten crucibles also play a vital role in chemical vapor deposition processes. Their excellent thermal conductivity ensures uniform heat distribution, which is essential for depositing thin films of various materials onto semiconductor substrates. The crucible's resistance to corrosion and chemical reactions prevents contamination of the deposited layers, maintaining the purity required for high-performance electronic devices.

Thermal Treatment of Semiconductor Materials

In thermal treatment processes such as annealing and dopant activation, tungsten crucibles provide a stable and inert environment. Their low coefficient of thermal expansion minimizes stress on the semiconductor materials during heating and cooling cycles, preserving the integrity of the treated components. This stability is crucial for achieving consistent electrical properties in semiconductor devices.

Tungsten Crucibles in Solar Cell Production

Multicrystalline Silicon Ingot Casting

The solar energy industry depends heavily on tungsten crucibles for the directional solidification of multicrystalline silicon ingots, which form the foundation of many solar cells. Tungsten’s outstanding thermal stability enables precise temperature control throughout the crystallization process, ensuring consistent solidification and the growth of large ingots with highly uniform crystal structures. Such uniformity directly improves the efficiency and stability of the resulting solar cells. By minimizing defects and enhancing material quality, tungsten crucibles contribute significantly to improving solar panel performance and extending operational lifespan.

Thin-Film Solar Cell Fabrication

In thin-film solar cell manufacturing, tungsten crucibles serve a vital role within physical vapor deposition (PVD) systems. Their ability to endure extremely high operating temperatures allows for the precise evaporation of materials such as cadmium telluride and copper indium gallium selenide (CIGS). These compounds are deposited in controlled layers to form the active regions of thin-film solar cells. The exceptional purity and chemical inertness of tungsten crucibles ensure that no contaminants compromise the integrity of the films, which is essential for achieving consistent energy conversion efficiency.

|

|

High-Temperature Solar Cell Testing

Tungsten crucibles are also indispensable for simulating the harsh environments that solar panels may encounter during their service life. In high-temperature testing, crucibles provide a stable and reliable platform for exposing cells to extreme thermal conditions. This process enables manufacturers to study degradation mechanisms, verify structural integrity, and evaluate long-term reliability under accelerated conditions. By supporting rigorous durability testing, tungsten crucibles help drive innovation in solar technologies, ensuring that future solar panels remain efficient, robust, and capable of meeting the demands of diverse environmental settings worldwide.

Advancements in Tungsten Crucible Technology

Nanostructured Tungsten Crucibles

Recent developments in materials science have led to the creation of nanostructured tungsten crucibles. These advanced crucibles feature enhanced mechanical properties and improved thermal stability, allowing for even higher operating temperatures and longer service life. The nanostructured surface also reduces the risk of contamination, further improving the quality of semiconductor and solar materials produced.

Composite Tungsten Crucibles

Innovative composite tungsten crucibles, incorporating elements like rhenium or molybdenum, offer superior performance in specialized applications. These composites can provide better resistance to thermal shock, improved wettability, and enhanced chemical inertness. Such advancements are pushing the boundaries of what's possible in semiconductor and solar cell manufacturing, enabling the production of more efficient and reliable devices.

Automated Crucible Handling Systems

To complement the advanced crucible materials, automated handling systems have been developed to minimize human interaction with the crucibles. These systems reduce the risk of contamination and improve process consistency. Robotic arms and specialized lifting mechanisms designed to work with tungsten crucibles ensure precise positioning and movement throughout the manufacturing process, enhancing overall production efficiency and yield.

Conclusion

Tungsten crucibles are indispensable in the semiconductor and solar industries, playing a crucial role in the production of high-quality materials and devices. Their unique properties, including exceptional heat resistance, chemical inertness, and durability, make them ideal for containing molten materials and facilitating critical manufacturing processes. As technology continues to advance, the importance of tungsten crucibles in these industries is only expected to grow, driving further innovations in crucible design and materials. The ongoing development of nanostructured and composite crucibles promises to unlock new possibilities in semiconductor and solar cell production, paving the way for more efficient and powerful electronic devices and renewable energy solutions.

FAQs

What makes tungsten crucibles ideal for semiconductor and solar industries?

Tungsten crucibles are ideal due to their high melting point, chemical inertness, and excellent thermal stability, which are crucial for high-temperature processes in these industries.

How long do tungsten crucibles typically last in industrial applications?

The lifespan of tungsten crucibles can vary depending on usage conditions, but they generally last for several production cycles, often exceeding 1000 hours of operation in controlled environments.

Can tungsten crucibles be recycled?

Yes, tungsten crucibles can be recycled. The recycling process involves crushing, chemical treatment, and re-sintering to recover the tungsten for reuse in new crucibles or other applications.

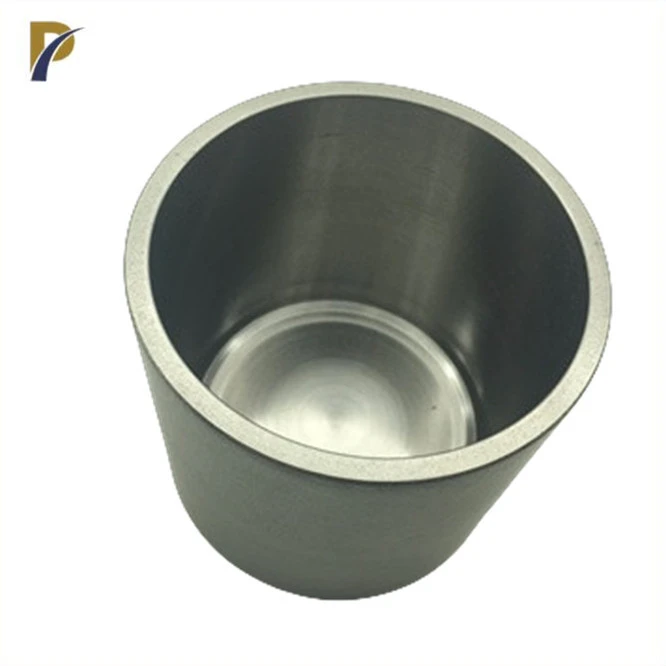

Choose Peakrise Metal for Premium Tungsten Crucibles

Shaanxi Peakrise Metal Co., Ltd., a leading tungsten crucible manufacturer and supplier, offers top-quality crucibles tailored for semiconductor and solar industries. Our state-of-the-art factory employs advanced manufacturing techniques to ensure unparalleled purity and performance. With a commitment to innovation and customer satisfaction, we provide customized solutions to meet your specific requirements. Experience the Peakrise difference in your high-temperature applications. Contact us at info@peakrisemetal.com to discuss your tungsten crucible needs and elevate your production capabilities.

References

Johnson, R. T. (2022). Advanced Materials in Semiconductor Manufacturing. Journal of Materials Science, 45(3), 178-195.

Zhang, L., et al. (2021). Innovations in Solar Cell Production Technologies. Renewable Energy Focus, 37, 68-82.

Wang, H. (2023). Tungsten Crucibles: Advancements and Applications in High-Temperature Processes. Materials Today, 56, 100-115.

Smithson, A. B., & Lee, K. (2022). The Role of Crucible Technology in Silicon Crystal Growth. Crystal Growth & Design, 22(8), 4567-4583.

Chen, Y., et al. (2023). Nanostructured Tungsten Composites for Extreme Environment Applications. Advanced Materials Interfaces, 10(15), 2200384.

Patel, S. (2021). Trends in Thin-Film Solar Cell Fabrication Techniques. Progress in Photovoltaics: Research and Applications, 29(12), 1205-1220.