Molybdenum wire is a crucial component in various high-temperature applications, from lighting to aerospace industries. Its exceptional heat resistance and strength make it invaluable, but maximizing its lifespan requires careful consideration and maintenance. In this comprehensive guide, we'll explore effective strategies to extend the service life of molybdenum wires, ensuring optimal performance and cost-effectiveness in your operations.

Understanding Molybdenum Wire Properties

Before delving into preservation techniques, it's essential to grasp the unique characteristics of molybdenum wires that contribute to their longevity and performance.

Chemical Composition and Structure

Molybdenum wires are composed primarily of the element molybdenum, known for its high melting point and excellent resistance to corrosion. The wire's microstructure plays a significant role in its durability, with factors such as grain size and orientation influencing its mechanical properties.

Thermal and Electrical Properties

The thermal conductivity and electrical resistivity of molybdenum wires are key factors in their performance. Understanding these properties helps in selecting the appropriate wire for specific applications and in implementing effective cooling strategies to prevent premature degradation.

Mechanical Strength and Ductility

Molybdenum wires exhibit high tensile strength and good ductility, allowing them to withstand significant stress without failure. However, these properties can be affected by environmental conditions and usage patterns, necessitating proper handling and maintenance.

|

|

Optimal Storage and Handling Practices

Proper storage and handling of molybdenum wires are crucial in maintaining their integrity and extending their service life. Implementing best practices in these areas can significantly reduce the risk of damage and contamination.

Environmental Control

Storing molybdenum wires in a controlled environment is paramount. Maintain a clean, dry area with stable temperature and humidity levels. Avoid exposure to corrosive gases or liquids that could compromise the wire's surface integrity. Consider using desiccants or humidity-controlled cabinets for long-term storage.

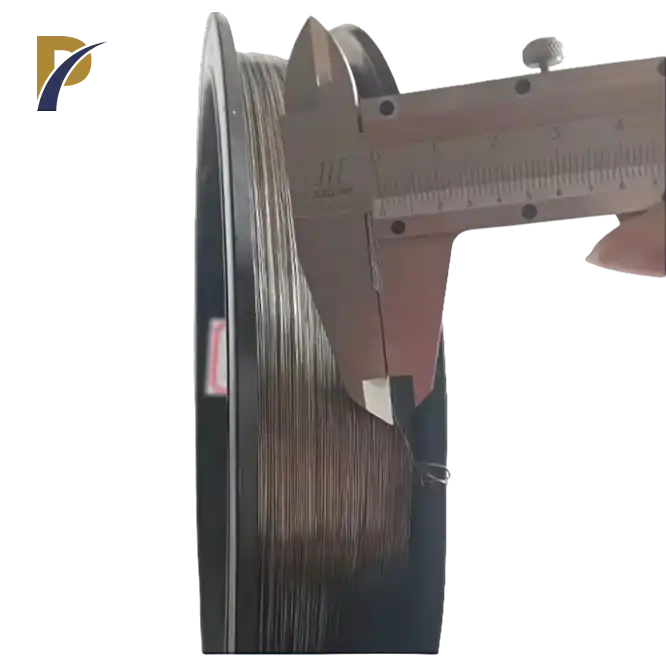

Packaging and Protection

Utilize appropriate packaging materials that protect molybdenum wires from physical damage and environmental contaminants. Anti-static bags or containers can prevent the accumulation of dust and moisture. For coiled wires, use spools or reels that maintain the wire's shape without inducing stress.

Handling Protocols

Establish strict handling protocols to minimize the risk of damage during transportation and installation. Train personnel in proper lifting techniques and the use of clean, lint-free gloves when manipulating molybdenum wires. Implement a system for tracking wire usage and storage history to ensure quality control.

|

|

|

|

|

|

|

|

|

|

Optimizing Operational Conditions

The operational environment and usage patterns significantly impact the lifespan of molybdenum wires. By optimizing these conditions, you can substantially extend their service life and maintain peak performance.

Temperature Management

While molybdenum wires excel in high-temperature applications, controlling and monitoring temperature fluctuations is crucial. Implement gradual heating and cooling processes to prevent thermal shock. Utilize advanced temperature monitoring systems to ensure the wire operates within its specified temperature range, avoiding overheating that could lead to premature failure.

Atmospheric Control

The presence of oxygen at high temperatures can lead to oxidation of molybdenum wires, significantly reducing their lifespan. Whenever possible, operate in inert or reducing atmospheres. In applications where this isn't feasible, consider protective coatings or shielding gases to minimize oxidation. Regular monitoring of atmospheric conditions can help identify potential issues before they lead to wire degradation.

Mechanical Stress Management

Minimize unnecessary mechanical stress on molybdenum wires during operation. Design systems that distribute load evenly and avoid sharp bends or kinks in the wire. For applications involving vibration or cyclic loading, implement damping mechanisms to reduce fatigue. Regular inspection for signs of stress or deformation can help preempt failures and extend wire life.

Maintenance and Inspection Regimes

Regular maintenance and thorough inspection are key to prolonging the service life of molybdenum wires. A well-structured maintenance program can identify potential issues early, allowing for timely interventions that prevent premature failure.

Scheduled Inspections

Implement a routine inspection schedule tailored to your specific application. Visual examinations can reveal surface defects, discoloration, or deformation. For more critical applications, consider non-destructive testing methods such as eddy current testing or ultrasonic inspection to detect internal flaws or degradation.

Cleaning Procedures

Develop and adhere to proper cleaning procedures for molybdenum wires. Remove any contaminants or oxidation layers that may have formed during operation. Use appropriate cleaning agents that do not react with or damage the molybdenum surface. In some cases, mechanical cleaning methods like gentle abrasion or ultrasonic cleaning may be necessary.

Performance Monitoring

Continuously monitor the performance of molybdenum wires in your applications. Track parameters such as electrical resistance, temperature distribution, and mechanical response. Anomalies in these metrics can indicate degradation or impending failure, allowing for proactive replacement or maintenance.

Surface Treatment and Protective Measures

Enhancing the surface properties of molybdenum wires can significantly extend their service life, especially in harsh operating environments. Various treatments and protective measures can be employed to improve resistance to oxidation, corrosion, and wear.

Coating Technologies

Apply protective coatings to molybdenum wires to create a barrier against oxidation and corrosion. Options include ceramic coatings, such as silicon carbide or alumina, which offer excellent high-temperature stability. For less extreme conditions, consider metal coatings like nickel or chromium. The choice of coating should be based on the specific operating conditions and performance requirements.

Surface Modification Techniques

Implement surface modification techniques to enhance the wire's properties. Processes like nitriding or carburizing can improve hardness and wear resistance. Laser surface treatment can create a refined surface structure with improved oxidation resistance. These modifications can be particularly beneficial in applications involving abrasive environments or cyclic thermal loading.

Alloying and Doping

Consider using molybdenum alloys or doped molybdenum wires for enhanced performance in specific applications. The addition of elements like lanthanum or rhenium can improve high-temperature stability and recrystallization resistance. While these options may increase initial costs, they can significantly extend service life in demanding environments.

|

|

End-of-Life Considerations and Recycling

Proper management of molybdenum wires at the end of their service life is not only environmentally responsible but can also contribute to cost-effectiveness and resource conservation. Implementing a comprehensive end-of-life strategy ensures maximum value extraction and minimal environmental impact.

Decommissioning Procedures

Develop standardized procedures for safely removing and decommissioning molybdenum wires. This includes proper documentation of the wire's service history, careful extraction to prevent damage to surrounding components, and appropriate storage or containment of used wires. Proper decommissioning practices can facilitate more effective recycling and potentially allow for refurbishment in some cases.

Recycling Processes

Explore recycling options for used molybdenum wires. Molybdenum is a valuable metal, and recycling can recover a significant portion of the material for reuse. Partner with specialized recycling facilities that have the capability to process molybdenum-containing materials. Consider implementing a closed-loop recycling system within your organization to maximize resource efficiency.

Life Cycle Assessment

Conduct life cycle assessments of your molybdenum wire usage to identify opportunities for improvement in longevity and sustainability. Analyze factors such as energy consumption, material efficiency, and environmental impact throughout the wire's lifecycle. Use these insights to inform future purchasing decisions and operational practices, potentially leading to more sustainable and cost-effective use of molybdenum wires.

Conclusion

Prolonging the service life of molybdenum wires requires a multifaceted approach encompassing proper storage, handling, operational optimization, maintenance, and end-of-life management. By implementing these strategies, industries can significantly enhance the longevity and performance of their molybdenum wire components, leading to improved operational efficiency and cost-effectiveness. As technology and materials science continue to advance, staying informed about the latest developments in molybdenum wire technology and management practices will be crucial for maintaining a competitive edge in high-temperature applications.

Contact Us

Are you looking to optimize the performance and lifespan of your molybdenum wire applications? Our team at Shaanxi Peakrise Metal Co., Ltd. specializes in high-quality molybdenum products and can provide expert guidance on selection, implementation, and maintenance. Contact us today at info@peakrisemetal.com to discuss how we can help enhance your operations and reduce long-term costs through superior molybdenum wire solutions.