Glass fabricating is an industry that requests outrageous accuracy and resilience, particularly with regards to the gear utilized in the creation cycle. One significant part in glass furnaces is the molybdenum electrode, known for its ability to outstanding to endure high temperatures. In this thorough aide, we'll investigate the amazing properties of molybdenum electrode for glass furnaces and how they figure out how to endure such cruel circumstances.

The Unique Properties of Molybdenum Electrodes

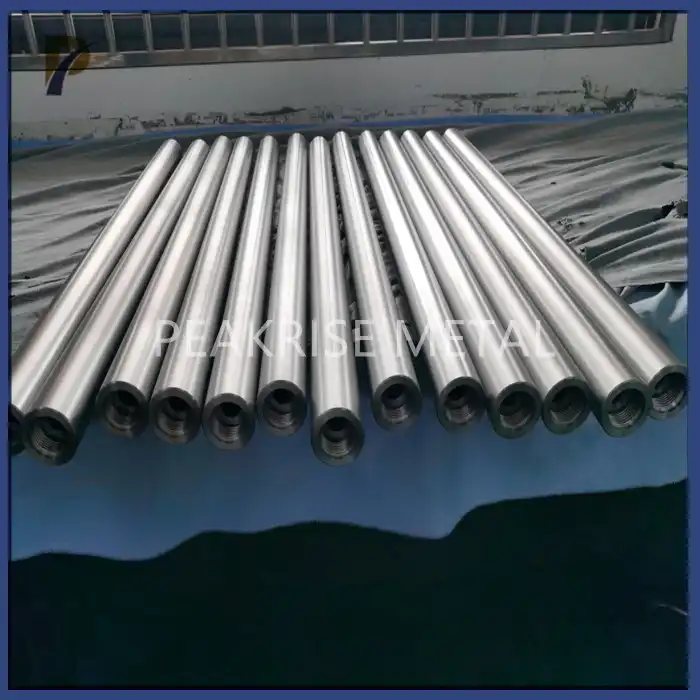

Molybdenum electrodes are a cornerstone in glass furnace operations, playing a vital role in the melting and refining of glass. Their exceptional performance under extreme conditions is attributed to several key characteristics:

High Melting Point

Molybdenum flaunts a stunningly high melting point of roughly 2,623°C (4,753°F). This uncommon thermal resistance permits molybdenum electrodes to keep up with their primary honesty in any event, when presented to the searing temperatures inside glass furnaces, which can reach up to 1,700°C (3,092°F).

Low Thermal Expansion

The coefficient of thermal expansion for molybdenum is relatively low compared to many other metals. This property is crucial in glass furnace applications, as it minimizes the risk of thermal shock and helps maintain the electrode's shape and dimensions even under rapid temperature fluctuations.

Excellent Electrical Conductivity

Molybdenum exhibits superior electrical conductivity, which is essential for efficient heat generation in glass furnaces. This property allows for the effective transfer of electrical energy into heat, ensuring uniform glass melting and refining processes.

|

|

Mechanisms of Heat Resistance in Molybdenum Electrodes

The ability of molybdenum electrodes for glass furnace to withstand high temperatures in glass furnaces is not solely due to their inherent properties. Several mechanisms contribute to their exceptional heat resistance:

Formation of Protective Oxide Layer

Molybdenum undergoes oxidation when heated in the presence of oxygen, resulting in the formation of a protective oxide layer on its surface. This layer is dominatingly made out of molybdenum trioxide (MoO3), which assumes a basic part in safeguarding the material from additional debasement. Going about as a hindrance, it keeps extra oxygen from entering further into the metal, in this manner saving the structural integrity of molybdenum, particularly in cruel conditions like high-temperature furnaces. This regular defensive system upgrades the toughness and execution of molybdenum-based electrodes under outrageous circumstances.

Recrystallization Process

When subjected to high temperatures, molybdenum experiences a recrystallization process, during which new, strain-free grains begin to form within the metal. This process relieves internal stresses and refines the metal’s grain structure, improving its mechanical strength. The formation of these new grains also contributes to enhanced heat resistance, making molybdenum more resilient in demanding thermal environments. As a result, this recrystallization not only strengthens the metal but also improves its stability and performance under prolonged exposure to high temperatures.

Thermal Stress Management

In the design and production of molybdenum electrodes for glass furnace, thermal stress management is a critical focus. Engineers carefully consider factors like the shape and size of the electrode, the implementation of efficient cooling systems, and proper installation techniques to control thermal gradients. By minimizing these temperature differences, the risk of thermal fatigue, which can lead to cracks or material failure, is significantly reduced. These design strategies ensure that the electrodes can withstand the intense thermal cycles encountered in high-temperature applications, prolonging their lifespan and maintaining reliable performance.

Optimizing Molybdenum Electrode Performance in Glass Furnaces

While molybdenum electrodes possess inherent qualities that make them suitable for high-temperature applications, several strategies can be employed to further enhance their performance and longevity in glass furnaces:

Proper Electrode Design

The design of molybdenum electrodes for glass furnace is essential for their durability in high-temperature environments. Key factors like shape, size, and surface area are meticulously optimized to promote even heat distribution. This careful design minimizes the risk of localized hot spots, which could otherwise cause premature failure, ensuring long-lasting performance under extreme conditions.

Advanced Manufacturing Techniques

Advanced manufacturing techniques, such as powder metallurgy and hot isostatic pressing, are used to produce molybdenum electrodes with superior purity, density, and mechanical strength. These processes allow for a more refined microstructure, resulting in enhanced heat resistance and durability. By improving these critical properties, these methods ensure that molybdenum electrodes perform more reliably and efficiently, even in demanding high-temperature applications.

Cooling System Integration

Integrating efficient cooling systems is vital for extending the lifespan of molybdenum electrodes in glass furnaces. By utilizing water-cooled electrode holders and strategically designed cooling channels, excess heat is effectively dissipated, ensuring stable operating temperatures. This helps prevent overheating and reduces the risk of thermal degradation, significantly enhancing the electrodes' durability and performance in high-temperature environments. Proper cooling management ensures more reliable operation and longer service life.

Conclusion

All in all, the striking skill of molybdenum electrodes to endure high temperatures in glass furnaces is a consequence of their extraordinary properties, modern plan, and high-level assembling methods. As the glass business keeps on developing, the job of molybdenum electrodes for glass furnace stays essential in guaranteeing proficient and solid glass creation processes.

Contact Us

For more information about our high-quality molybdenum electrodes for glass furnaces and other non-ferrous metal products, please contact Shaanxi Peakrise Metal Co., Ltd. at info@peakrisemetal.com. Our team of experts is ready to assist you in finding the perfect solution for your glass manufacturing needs.

References

Johnson, R. T., & Smith, A. B. (2019). Advanced Materials in Glass Manufacturing: The Role of Molybdenum Electrodes. Journal of Glass Technology, 45(3), 278-295.

Zhang, X., & Li, Y. (2020). Thermal Properties and Oxidation Behavior of Molybdenum in High-Temperature Environments. Materials Science and Engineering: A, 780, 139185.

Brown, C. D., & Davis, E. F. (2018). Optimization of Electrode Design for Glass Melting Furnaces. International Journal of Heat and Mass Transfer, 126, 1121-1135.

Patel, S., & Kumar, R. (2021). Recent Advances in Molybdenum-based Materials for Extreme Temperature Applications. Progress in Materials Science, 117, 100721.

Anderson, L. M., & Wilson, K. J. (2017). Electrochemical Aspects of Glass Melting: The Role of Molybdenum Electrodes. Journal of the American Ceramic Society, 100(9), 3962-3975.

Takahashi, H., & Yamamoto, T. (2022). Long-term Performance Evaluation of Molybdenum Electrodes in Industrial Glass Furnaces. Journal of Materials Engineering and Performance, 31(4), 2789-2801.