0.05mm High Purity Zirconium Foil for Corrosion Resistance

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

0.05mm High Purity Zirconium Foil for Corrosion Resistance – Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

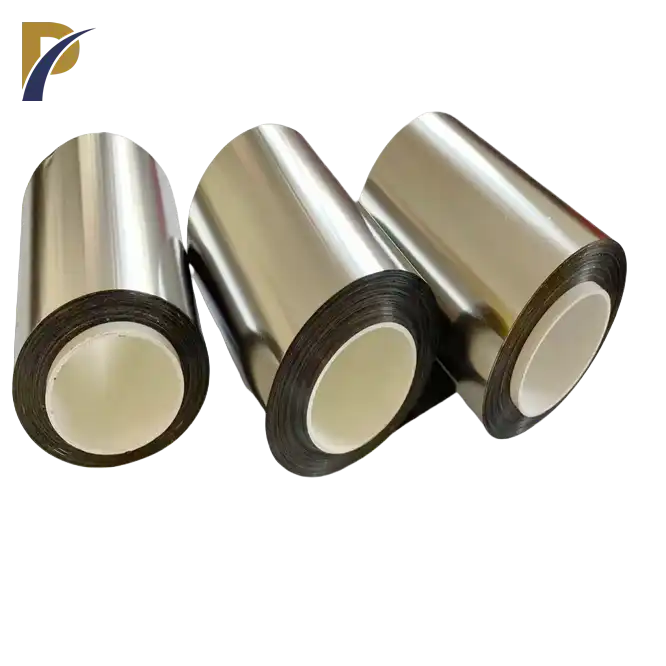

0.05mm High Purity Zirconium foil is widely recognized for its excellent corrosion resistance, particularly in aggressive environments like acid, alkali, and saltwater conditions. Its superior resistance to corrosion and high melting point make it a key material in industries such as chemical processing, nuclear power, and aerospace. The zirconium used in our foils is meticulously refined to ensure top-quality and unmatched performance, making it ideal for highly demanding applications.

At Shaanxi Peakrise Metal Co., Ltd., we specialize in providing high-purity zirconium foil with exceptional corrosion-resistant properties. Our extensive experience in producing and supplying non-ferrous metals like zirconium allows us to deliver customized solutions for a broad range of industrial needs. Whether you require zirconium foil for chemical processing equipment or nuclear fuel applications, we provide materials that meet stringent global standards. Our expertise, coupled with advanced manufacturing processes, ensures that we offer zirconium foil that meets the most exacting requirements.

Product Specifications

| Pame | 0.05mm High Purity Zirconium Foil for Corrosion Resistance |

| Material | Zirconium & Zirconium alloy |

| Grade | Zr702,Zr704,Zr705,RO60001,RO60901,RO60804 |

| Purity | >99.5% |

| Density | 6.51g/cm3 |

| Standard | ASTM B551 |

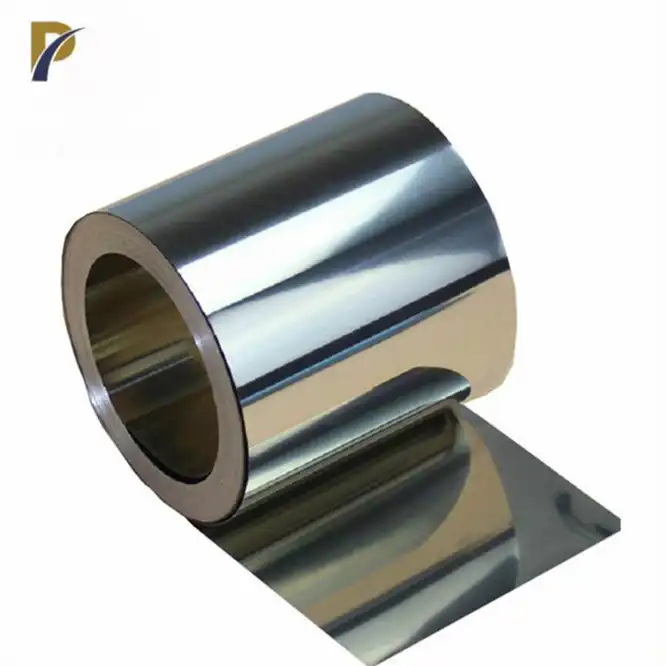

| Size | 0.05mm*200*Lmm |

| Shape | Plate/sheet |

| Surface | Polished |

| MOQ | 1kg |

| Custom | Yes, we can OEM,ODM |

| Package | Plywood case |

| Country of origin | Shaanxi,China |

| Application | 1.Chemical processing,medicalinstruments etc. 2.Aerospace,Indusrty,Navigation,Smelting,Chemical plants,and soon. 3.Plate heat exchanger, andcondensers 4.Chemical and medicalequipment. |

|

|

|

Physical and Chemical Properties

Zirconium foil stands out for its physical and chemical properties that enable it to perform in highly corrosive environments. Its high resistance to hydrochloric acid, sulfuric acid, and seawater corrosion makes it an excellent choice for industries that demand long-lasting materials. Additionally, zirconium has low thermal expansion, a high melting point, and excellent mechanical strength, even under high-temperature conditions.

| Surface: | The sheets are free from impurities, splits, fractures and indentations,having an impact on a common processing or application of the product. |

| Surface roughness: | Cold rolled. bright: Ra ≤ 0.80 μm Cold rolled. ground: Ra ≤ 1.20 μm Cold rolled. pickled (dull): Ra ≤ 1.60 μm |

Product Applications

-

Chemical Processing Industry

Zirconium foil’s corrosion-resistant properties make it perfect for use in chemical reactors, heat exchangers, and piping systems that handle aggressive acids and alkaline substances. -

Nuclear Power Industry

Due to its low neutron-capture cross-section and resistance to radiation damage, zirconium foil is widely used in nuclear reactors for fuel cladding and other critical components. -

Aerospace and Defense

In aerospace, zirconium’s lightweight yet durable properties make it suitable for high-temperature environments, contributing to the development of advanced aviation and defense systems. -

Pharmaceutical and Medical Equipment

Zirconium’s biocompatibility makes it ideal for use in medical devices, surgical tools, and pharmaceutical equipment that require corrosion resistance and stability. -

Marine Engineering

Zirconium’s resistance to seawater makes it a preferred material for use in marine environments, particularly in saltwater desalination plants and naval engineering projects.

Manufacturing Process and Production Workflow

At Shaanxi Peakrise Metal Co., Ltd., our zirconium foil is produced using state-of-the-art techniques that ensure precision and consistency. The process begins with the selection of high-purity zirconium material, which is then melted in a vacuum arc furnace. This is followed by rolling the material into thin foils under controlled conditions to achieve the desired thickness. After rolling, the foils undergo rigorous testing to ensure that they meet industry standards for purity, thickness, and corrosion resistance. Each batch is then annealed in a vacuum furnace to improve mechanical properties and reduce internal stress.

Factory Introduction

Our factory at Shaanxi Peakrise Metal Co., Ltd. is equipped with advanced machinery such as vacuum arc melting furnaces, laser cutters, and rolling mills. With over a decade of experience in the non-ferrous metals industry, we have developed cutting-edge capabilities in the production and processing of materials like zirconium, titanium, and tantalum. Our comprehensive approach integrates research, development, and production to provide our customers with superior products that meet global standards.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging Options

- Wooden Box Packaging: Ideal for protecting large orders during shipping.

- Cardboard Box Packaging: Suitable for smaller, lightweight shipments.

- Foam-Filled Packaging: Provides an additional layer of protection against impact and vibrations.

- Waterproof and Moisture-Proof Packaging: Ensures the integrity of zirconium foil even in humid conditions.

- Custom Packaging: Tailored to meet specific customer needs, including size and labeling.

- International Standard Packaging: Complies with regulations for safe and secure global shipments.

Logistics Options

- Sea Freight: Cost-effective solution for large international shipments.

- Air Freight: Expedited shipping for urgent deliveries.

- Land Transport: Ideal for regional orders within specific countries or continents.

- Multimodal Transport: A combination of sea, air, and land transport for optimized delivery.

- Express Delivery: Available for smaller, time-sensitive orders.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

-

Experienced Manufacturer

With over a decade of experience in producing non-ferrous metals, we have the expertise and capabilities to deliver the highest-quality zirconium foil. -

High-Quality Materials

We use only high-purity zirconium in our production, ensuring that the foil meets or exceeds international standards. -

Advanced Manufacturing

Our factory is equipped with state-of-the-art machinery that allows us to produce zirconium foil with precision and consistency. -

Custom Solutions

We offer OEM/ODM services that cater to the specific requirements of our clients, whether it's custom sizes, thicknesses, or finishes. -

Global Reach

We have successfully exported our products to customers in over a dozen countries, building long-term relationships based on trust and quality.

-

What is the minimum order quantity (MOQ) for zirconium foil?

Our MOQ is flexible and depends on the specific requirements of the order. Please contact us for detailed information. -

Can I request a custom size for the zirconium foil?

Yes, we offer custom sizes to meet your specific needs. Please provide the desired thickness, width, and length. -

What are the lead times for production and delivery?

Lead times vary depending on the size and complexity of the order. Typically, production takes 3-4 weeks, and delivery times depend on the shipping method. -

Do you provide samples for testing?

Yes, we can provide small samples of zirconium foil for testing and evaluation. -

How do you ensure the quality of your products?

Our products undergo strict quality control at every stage of production, including material testing, thickness measurements, and corrosion resistance assessments.

Call to Action (CTA)

Contact Us

For more information about our high-quality Zirconium Foil for Corrosion Resistance, or to request a quote, feel free to contact us at info@peakrisemetal.com. We are committed to providing tailored solutions to meet the unique needs of your business. Let’s collaborate to deliver the best in non-ferrous metal products and services. Contact us today!