Chemical-Resistant Zirconium Foil

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

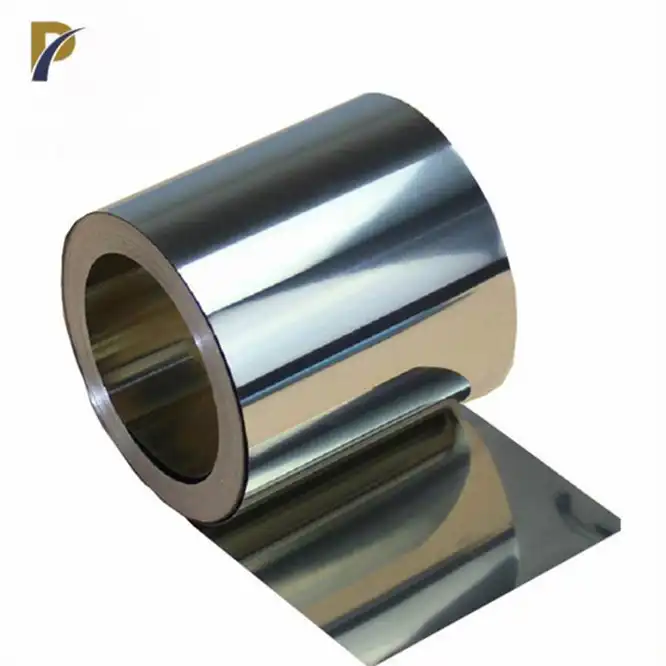

Chemical-Resistant Zirconium Foil: A Durable Solution for Harsh Environments

Product Introduction

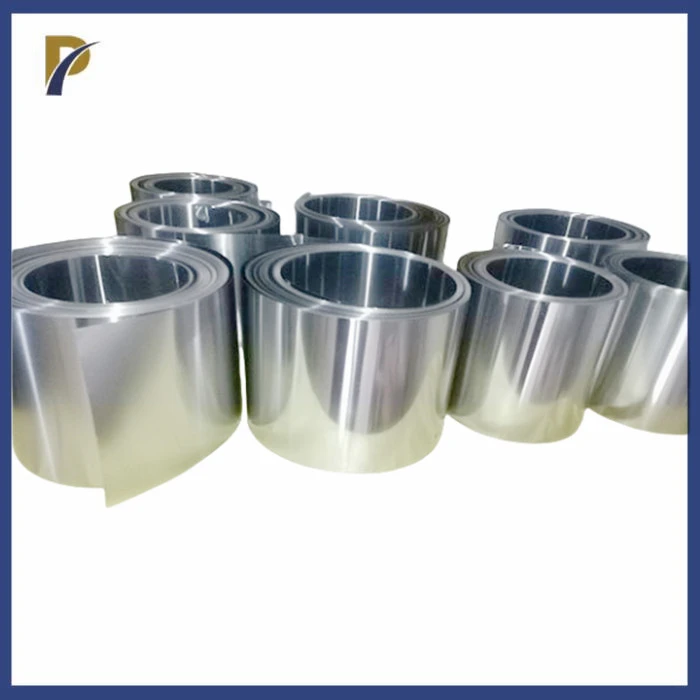

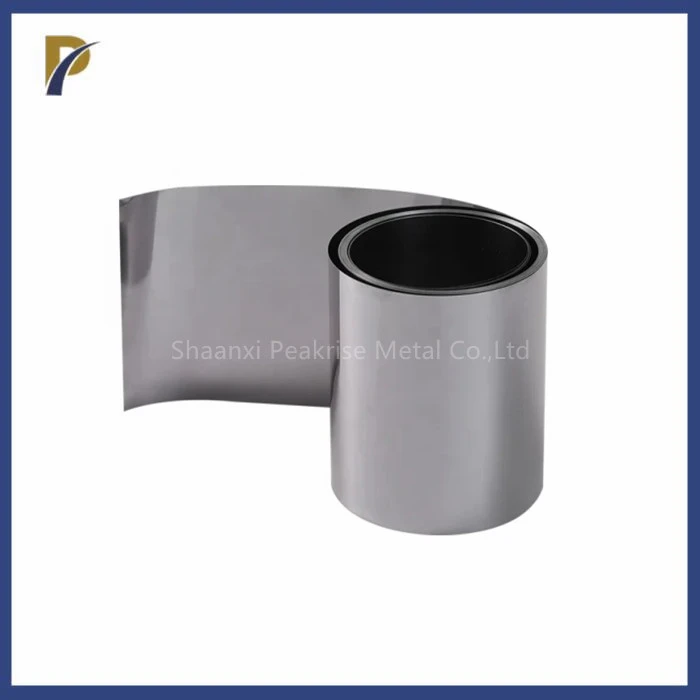

Chemical-resistant zirconium foil is one of the most essential materials for industries that demand high durability and resilience under extreme chemical conditions. As a leading supplier of zirconium products, Shaanxi Peakrise Metal Co., Ltd. provides high-quality chemical-resistant zirconium foil to global markets, ensuring superior performance in highly corrosive environments. Zirconium is known for its remarkable resistance to corrosion, especially in acidic environments where most metals degrade. This property makes zirconium foil an indispensable material in various industrial applications, particularly in chemical processing, nuclear power plants, and medical devices.

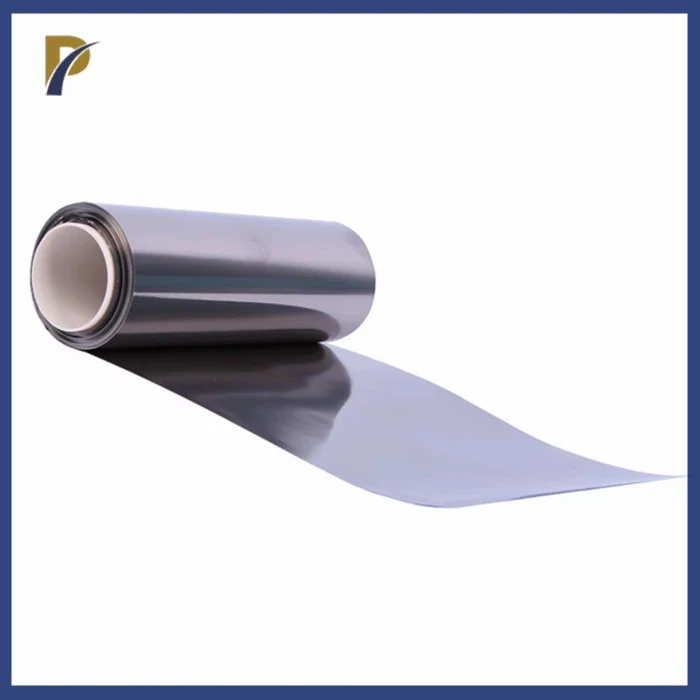

At Shaanxi Peakrise Metal Co., Ltd., we produce zirconium foil with top-grade Zr702 and Zr705 alloys, renowned for their excellent mechanical properties and exceptional resistance to chemical attacks. With years of experience and advanced manufacturing capabilities, we deliver zirconium foil that meets the stringent standards of different industries worldwide. Our chemical-resistant zirconium foil is manufactured through precise rolling processes, ensuring uniform thickness, smooth surface finish, and excellent ductility. Whether you need a small or large quantity, we offer customized sizes and thicknesses to match your project requirements.

Product Specifications

| Property | Zr702 | Zr705 |

|---|---|---|

| Purity | 99.2% | 97.5% |

| Thickness Range | 0.02-0.5 mm | 0.02-0.5 mm |

| Width Range | 50-400 mm | 50-400 mm |

| Tensile Strength | 379 MPa | 690 MPa |

| Elongation | 16% | 18% |

| Melting Point | 1855°C | 1855°C |

| Density | 6.51 g/cm³ | 6.50 g/cm³ |

Product Name: Zirconium foil

Grade: Zr702,Zr705,Zr60804,Zr60001

Material: Zirconium & Zirconium alloy

Thickness: min 0.02mm

Width: <500mm

Standard: ASTM B551

Processing: hot rolling or cold rolling

Condition: annealed

Chemical Properties

| Grade | Element composition(%)< | Standard | ||||||||

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | ||

| R60702 | 99.2 | 4.5 | 0.20 | -- | 0.005 | 0.025 | 0.05 | -- | 0.16 | ASTM B551 |

| R60703 | 98 | 4.5 | -- | -- | --0.005 | 0.025 | -- | -- | -- | |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | -- | 0.18 | |

| R60705 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 | |

| R60706 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 | |

|

|

|

|

|

|

Product Features

-

Exceptional Chemical Resistance

Zirconium foil's primary feature is its outstanding resistance to corrosive chemicals. This property makes it a top choice for industries that work with highly reactive substances such as hydrochloric acid and sulfuric acid. -

High-Temperature Stability

With a melting point of 1855°C, zirconium foil performs well in high-temperature environments, maintaining structural integrity even under thermal stress. -

Durability and Strength

Zirconium foil is not only resistant to chemicals but also provides high tensile strength, making it a robust material that can endure heavy wear and tear over time. -

Customizability

We provide zirconium foil in various thicknesses and sizes, ensuring flexibility in design and application for our clients' specific needs.

Applications of Chemical-Resistant Zirconium Foil

-

Chemical Processing Industry

Zirconium foil is widely used in the chemical processing industry due to its resistance to strong acids and alkaline solutions. It is an excellent material for constructing reactors, heat exchangers, and storage tanks. -

Nuclear Power Plants

In the nuclear industry, zirconium's low neutron absorption properties make it the ideal material for cladding nuclear fuel rods, ensuring safe and efficient energy production. -

Medical Devices

Zirconium foil's biocompatibility makes it suitable for medical implants, surgical instruments, and other healthcare devices that require chemical stability and non-toxicity. -

Aerospace Industry

The aerospace industry benefits from zirconium foil's lightweight and corrosion-resistant properties, using it in components that require longevity in harsh environments.

|

|

Production Process & Manufacturing Technology

At Shaanxi Peakrise Metal Co., Ltd., we utilize cutting-edge technology to ensure our zirconium foil meets the highest quality standards. Our production process includes the following steps:

-

Vacuum Arc Melting

This method is used to create zirconium ingots by melting the raw materials in a controlled environment, which ensures the material's purity. -

Rolling

After the ingot is created, it is passed through advanced rolling mills to achieve the desired thickness and uniformity. -

Annealing

The foil is then subjected to a heat treatment process to enhance its ductility, making it easier to form into different shapes while maintaining strength. -

Surface Finishing

Our finishing process ensures the foil has a smooth and clean surface, free from imperfections.

Why Choose Shaanxi Peakrise Metal Co., Ltd.?

-

Extensive Experience

With over a decade of experience in the non-ferrous metal industry, we have the expertise to deliver high-quality products tailored to our clients' needs. -

State-of-the-Art Equipment

We employ advanced machinery such as vacuum arc melting furnaces, rolling mills, and annealing ovens, ensuring precise production of zirconium foil. -

Global Reach

We have established long-term partnerships with clients in over 20 countries, ensuring our products are trusted worldwide. -

Comprehensive Customization

We offer flexible production capabilities to match your exact specifications, including custom thicknesses, widths, and lengths of zirconium foil.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. provides comprehensive OEM and ODM services, allowing you to customize the size, thickness, and packaging of our chemical-resistant zirconium foil to meet your unique requirements. We are committed to working closely with you to develop tailored solutions that fit your business needs, ensuring both quality and efficiency.

|

|

|

Logistics and Packaging

-

Packaging

- Wooden crate packaging

- Foam-filled packaging

- Waterproof and moisture-resistant packaging

- Custom packaging solutions tailored to client specifications

- Packaging that meets international shipping standards

-

Logistics

- Ocean freight

- Air freight

- Land transport

- Multimodal transportation options

- Expedited shipping services available upon request

|

|

|

|

|

|

|

|

|

|

Frequently Asked Questions (FAQ)

-

What is the purity of your zirconium foil?

Our zirconium foil typically has a purity of 99.2% for Zr702 and 97.5% for Zr705. -

Can you provide customized sizes for zirconium foil?

Yes, we offer custom thicknesses and dimensions based on your specific requirements. -

What industries can benefit from zirconium foil?

Industries such as chemical processing, nuclear energy, aerospace, and medical sectors can greatly benefit from the use of zirconium foil. -

How is your zirconium foil packaged for shipping?

We use international standard packaging, including wooden crates and foam inserts, to ensure safe transportation. -

What are your typical delivery times?

Delivery times vary based on the quantity and location but typically range from 2 to 4 weeks.

Contact Us

Ready to enhance your production with high-quality chemical-resistant zirconium foil? Contact us today at info@peakrisemetal.com to learn more about how Shaanxi Peakrise Metal Co., Ltd. can supply the materials you need to stay competitive in your industry. We look forward to collaborating with you on your next project!