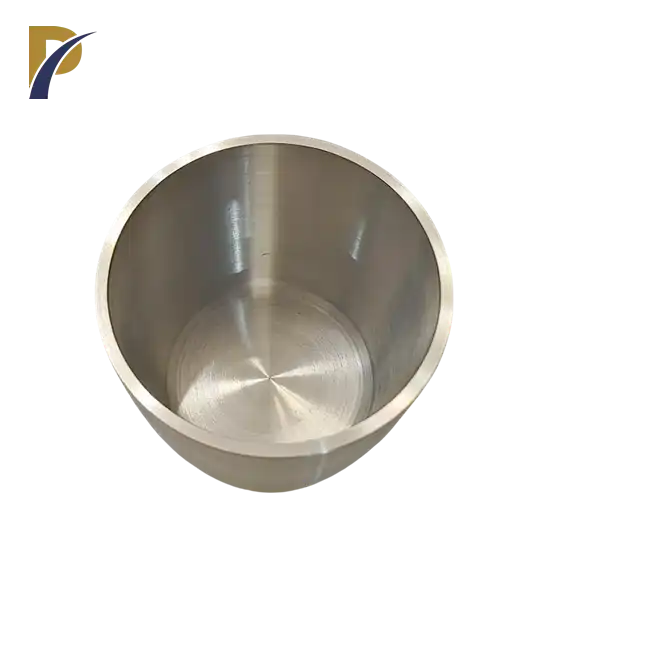

Low form Laboratory Analysis Zirconium Crucible

Name: ICP-OES Laboratory Purification Zirconium Crucible

Material: Zirconium & Zirconium Alloy

Grade: Zr702,Zr705,R60001,R60901

Shape: Crucible

Type: Low Form Zirconiu Crucible, Flanged Rims Zirconium Crucible,straight Wall Zirconium Crucible, Tapered Zirconium Crucible, Cylindrical Zirconium Crucible

Density: 6.51g/cm3

Size: 5ml,10ml,15ml,25ml,30ml,35ml,40ml,45ml Etc.

Custom: Yes

MOQ: 5pcs

Advantage: Corrosion Resistant, Good Mechanical Strength At High Temperatures

PRODUCT DESCRIPTION

Product Introduction: Low form Laboratory Analysis Zirconium Crucible

Shaanxi Peakrise Metal Co., Ltd. is a globally recognized supplier of high-quality Laboratory Analysis Zirconium Crucible. This material is widely used in the metallurgy, foundry, and industrial ceramics industries due to its exceptional thermal properties and chemical resistance. Laboratory Analysis Zirconium Crucible is highly suitable for environments requiring extreme heat resistance and corrosion protection, making it ideal for use in applications such as metal melting and casting, high-temperature furnace linings, and other critical high-performance applications.

As a trusted supplier, Shaanxi Peakrise Metal Co., Ltd. provides top-grade Laboratory Analysis Zirconium Crucible that are known for their durability and reliability under extreme conditions. We leverage over a decade of experience in producing non-ferrous metals, including tungsten, molybdenum, tantalum, niobium, titanium, and zirconium. With extensive experience in international trade and a strong commitment to product quality, we have established long-term partnerships with clients in countries such as the United States, Germany, South Korea, and Australia. Our Laboratory Analysis Zirconium Crucible is designed to meet the most stringent industrial requirements, ensuring optimal performance and longevity in high-temperature applications.

Shaanxi Peakrise Metal supplies various kinds of zirconium crucible. Customization is available by your request.

|

|

Product Parameters

| Low form Zirconium crucible | |||||

| Top diameter(mm) | Bottom diameter (mm) | Height (mm) | Wall thickness (mm) | Capacity (ml) | |

| 22 | 18 | 20 | 2 | 3.6ml | |

| 26 | 16 | 20 | 2 | 5.0ml*2mm | |

| 30 | 24 | 26 | 2 | 10ml*2mm | |

| 40 | 26 | 41 | 1 | 30ml*1mm | |

| 42 | 27 | 42 | 2 | 30ml*2mm | |

| 42 | 30 | 42 | 1.6 | 35ml*1.6mm | |

| 41 | 33 | 42 | 2 | 35ml*2mm | |

| 43 | 34 | 40 | 1 | 40ml*1mm | |

| 47 | 40 | 35 | 1 | 45ml*1mm | |

| 49 | 42 | 36 | 2 | 45ml*2mm | |

| 48 | 38 | 45 | 3 | 45ml*3mm | |

| 47 | 40 | 38.5 | 1 | 50ml*1mm | |

| 48 | 40 | 42 | 2 | 50ml*2mm | |

| 56 | 44 | 50 | 2 | 80ml*2mm | |

| AutoFluxer crucible with flanged | |||||

| 48 | 29 | 33 | 2 | 25ml*2mm | |

| 60 | 36 | 39 | 1 | 50ml*1mm | |

| 60 | 36 | 43 | 2 | 50ml*2mm | |

We can process various crucibles according to customer drawings.We are a professional manufacturer of zirconium crucibles in China. We can produce zirconium crucibles of various specifications and shapes. We export fixed quantities every month to countries rich in mineral resources such as Australia and South Africa.

Product Applications

- Metal Melting and Casting:Low form Laboratory Analysis Zirconium Crucible are commonly used in metal smelting and casting processes where high-temperature stability and chemical resistance are required.

- Furnace Linings: With its exceptional heat resistance, zirconium is often used in the linings of high-temperature furnaces for the production of steel, aluminum, and other metals.

- Industrial Ceramics: Low form Laboratory Analysis Zirconium Crucible play a critical role in the production of advanced ceramics, ensuring the material’s integrity at extremely high temperatures.

- Aerospace Components: The material’s strength and resistance to high heat make it suitable for aerospace applications, including turbine components and other high-temperature parts.

- Laboratory Equipment: Low form Laboratory Analysis Zirconium Crucible are also used in scientific research laboratories, particularly for high-temperature experiments and chemical analysis.

|

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM and ODM services, allowing our clients to customize their zirconium oxide crucibles to meet specific industrial needs. Our team of experts works closely with customers to provide tailor-made solutions, ensuring the product specifications align with their requirements. We specialize in the production of custom shapes, sizes, and compositions, delivering high-quality products with quick turnaround times.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Extensive Industry Experience: With over ten years of expertise in non-ferrous metal production, Shaanxi Peakrise Metal Co., Ltd. has a deep understanding of the industry and its unique demands.

- Global Reach: We supply high-quality zirconium oxide crucibles to clients across the globe, including in the United States, Germany, South Korea, and Australia.

- Advanced Manufacturing Capabilities: Our state-of-the-art production facilities are equipped with intermediate frequency sintering furnaces, vacuum arc melting furnaces, and more to ensure the highest quality standards.

- Comprehensive Product Range: We offer a wide variety of non-ferrous metal products, including tungsten-copper alloys, molybdenum-copper alloys, and tantalum alloys, making us a one-stop solution for metal needs.

- Customer-Centric Approach: We prioritize customer satisfaction, offering flexible solutions and fast response times to meet your industrial requirements.

FAQ

-

What is the maximum temperature the zirconium oxide crucibles can withstand?

Our zirconium oxide crucibles can withstand temperatures up to 2400°C, making them ideal for high-temperature industrial applications. -

Are custom sizes available for induction crucible zirconium oxide?

Yes, we offer customizable sizes and shapes to meet the specific needs of your operation. Our OEM services are designed to provide flexible solutions. -

How do zirconium oxide crucibles perform in chemically aggressive environments?

Zirconium oxide crucibles exhibit excellent resistance to acids and alkalis, ensuring durability even in the most chemically aggressive conditions. -

What are the typical applications of zirconium oxide crucibles?

Our zirconium oxide crucibles are widely used in metal melting, high-temperature furnace linings, industrial ceramics, and laboratory applications. -

What packaging options are available for zirconium oxide crucibles?

We offer a range of packaging options, including wooden crates, foam-filled boxes, and moisture-resistant materials to ensure safe delivery.

Packaging and Logistics

-

Packaging:

- Wooden Crates for large, heavy crucibles.

- Cardboard boxes with foam inserts for smaller products.

- Waterproof and moisture-resistant materials.

- Custom packaging based on customer specifications.

- All packaging meets international standards to ensure safe transport.

-

Logistics:

- Sea Freight for large, bulk orders.

- Air Freight for urgent deliveries.

- Land Transport for domestic and cross-border shipments.

- Multimodal Transport combining sea, air, and land for maximum efficiency.

- Courier Services for small, lightweight shipments.

|

|

|

|

|

|

|

|

|

|

Contact Us

Ready to experience the high performance of our induction crucible zirconium oxide? Contact us today to discuss your requirements and request a quote. Our expert team is here to assist you with custom solutions and answer any questions. Let us help you elevate your operations with high-quality, reliable zirconium oxide crucibles.

For inquiries, please contact us at: info@peakrisemetal.com. We look forward to working with you!