type sic heating element for furnace

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

Product Introduction: Type SiC Heating Elements

Shaanxi Peakrise Metal Co., Ltd. is a renowned global supplier of Type SiC (Silicon Carbide) heating elements, providing high-quality solutions to a broad range of industries. Silicon carbide heating elements are known for their high temperature endurance, durability, and efficiency in industrial applications. These elements are widely used in electric furnaces and kilns, particularly in ceramics, metallurgy, and glass manufacturing due to their ability to withstand extreme temperatures of up to 1600°C. The product is not only robust but also exhibits a long service life, reducing operational downtime and maintenance costs.

At Shaanxi Peakrise Metal Co., Ltd., we understand the demands of high-temperature processing and offer a reliable supply of SiC heating elements that meet stringent international quality standards. With years of expertise in the production of non-ferrous metals and advanced materials, we ensure that our products offer optimal performance, longevity, and reliability for our clients worldwide.

|

|

Product Parameters

The following table presents the detailed parameters of our Type SiC heating elements. These values are carefully chosen to represent the highest standards of performance and efficiency.

| Parameter | Value |

|---|---|

| Maximum Operating Temperature | 1600°C |

| Density | 3.1 g/cm³ |

| Electrical Resistivity | 0.1-100 Ω·cm |

| Thermal Conductivity | 120 W/mK |

| Diameter Range | 10-54 mm |

| Length Range | 300-2000 mm |

| Parameter | Value |

|---|---|

| Material Composition | SiC (99%) |

| Resistance Tolerance | ±5% |

| Power Output | 1-25 kW |

| Maximum Surface Load | 5 W/cm² |

| Shape | Rod, U-shaped, W-shaped |

| Parameter | Value |

|---|---|

| Heating Element Type | Dumbbell, Rod, U, and W shapes |

| Electrical Insulation | None (SiC is a conductor) |

| Standard Packaging | Foam, wooden box, carton |

| Weight | 0.5-10 kg |

| Customization Available | Yes |

Physical and Mechanical Properties

SiC heating elements are characterized by their unique physical and mechanical properties, making them suitable for demanding industrial environments. The high melting point, excellent thermal conductivity, and mechanical strength of silicon carbide are the key features that enhance its performance in extreme heat conditions. These properties ensure uniform heating and energy efficiency, contributing to better control over temperature distribution in furnaces.

- High Melting Point: SiC heating elements can operate at temperatures up to 1600°C.

- Superior Thermal Conductivity: Ensures even heat distribution across the entire element surface.

- Durability: SiC is highly resistant to oxidation and corrosion, extending the life of the heating elements.

- Mechanical Strength: Excellent strength in both tension and compression, allowing the elements to withstand thermal cycling.

|

|

Product Functions

The Type SiC heating elements perform the following functions in industrial applications:

- High-Temperature Heating: SiC elements efficiently provide consistent heating for applications requiring temperatures above 1000°C.

- Energy Efficiency: These elements convert electrical energy into heat with high efficiency, minimizing energy consumption.

- Uniform Heat Distribution: Their structure ensures even temperature spread across the heating element, reducing cold spots in kilns or furnaces.

- Resistance to Oxidation: SiC elements maintain their integrity and performance even in oxidative environments, prolonging the operational life of the equipment.

- Easy Integration: Due to their standardized sizes and shapes, SiC elements can easily be integrated into various heating systems, offering flexibility in design.

Product Applications

Type SiC heating elements are widely used in the following industries and applications:

- Ceramics and Glass Manufacturing: These elements are critical in high-temperature furnaces used for sintering ceramics and glass production. They ensure precise temperature control, enhancing the quality of finished products.

- Metallurgy: In the smelting and refining of metals, SiC heating elements help maintain consistent heat, crucial for alloy production and metal processing.

- Heat Treatment Furnaces: Commonly used in furnaces for annealing, hardening, and tempering metals. SiC elements provide efficient heating in the range of 1200-1600°C.

- Laboratory Furnaces: SiC elements are also found in laboratory settings for material research and development, offering a stable and controllable heating source.

- Chemical Industry: Used in reactors and kilns for high-temperature chemical processing due to their resistance to harsh environments and chemical corrosion.

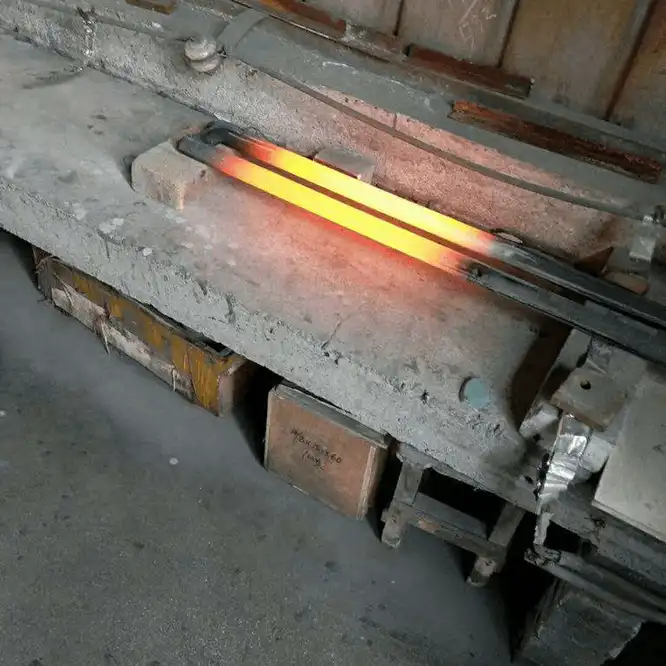

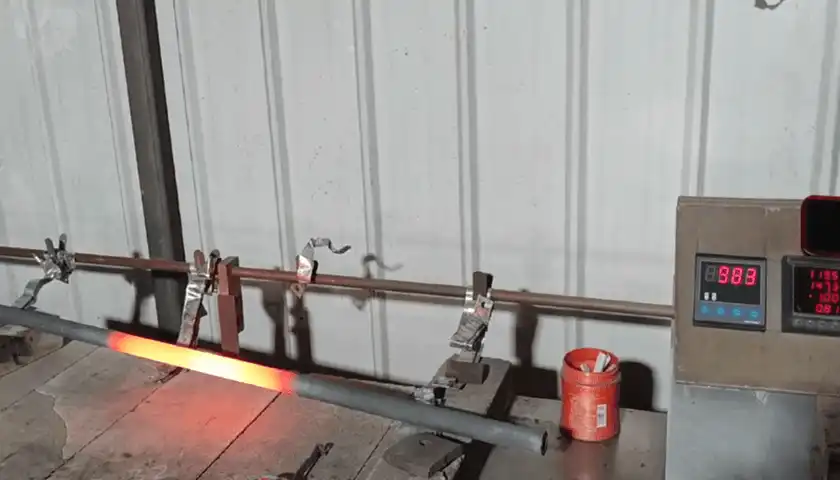

Product Process and Production Flow

Our production process involves high-precision techniques, ensuring the quality and performance of each SiC heating element:

- Raw Material Selection: High-purity silicon carbide powders are carefully sourced and tested for consistency.

- Forming: The powders are shaped into rods, tubes, or custom designs using high-pressure extrusion or molding processes.

- Sintering: The formed elements are sintered in intermediate frequency or vacuum furnaces, ensuring maximum density and structural integrity.

- Finishing: Elements undergo surface finishing to remove any imperfections, ensuring a smooth and conductive surface.

- Quality Testing: Each heating element is rigorously tested for electrical resistance, mechanical strength, and thermal performance.

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a state-of-the-art production facility equipped with advanced machinery, such as vacuum arc melting furnaces and plasma cutting machines. We pride ourselves on our ability to produce a wide range of non-ferrous metals and alloys, ensuring that every product meets the highest industry standards. Our factory is staffed with experienced engineers and technicians, and we maintain a comprehensive quality control system certified by ISO9001.

|

|

Logistics and Packaging

We offer secure and reliable packaging solutions to ensure that our products reach customers in perfect condition:

- Wooden Crate Packaging: Provides robust protection for large and heavy elements.

- Carton Packaging: Suitable for smaller orders, ensuring cost-effectiveness while maintaining safety.

- Foam-filled Packaging: Ensures that each element is cushioned against impact during transportation.

- Waterproof and Moisture-proof Packaging: Keeps the product safe from environmental factors during shipping.

- Custom Packaging: Available to meet specific customer requirements, ensuring compliance with international packaging standards.

Our logistics services cover:

- Sea Freight: Cost-effective for large, bulk orders.

- Air Freight: Fast delivery for urgent orders.

- Land Transport: Reliable service for domestic or neighboring regions.

- Multimodal Transport: A combination of transportation methods for optimal delivery efficiency.

- Courier Services: Door-to-door delivery for small or time-sensitive orders.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Expertise in Non-Ferrous Metals: With over a decade of experience, we are specialists in producing high-quality tungsten, molybdenum, tantalum, niobium, and titanium products.

- Comprehensive Production Facilities: Our advanced equipment ensures that we can handle large-scale production while maintaining stringent quality control.

- Global Reach: Our products are exported to over ten countries, with long-term partnerships established in the US, South Korea, Germany, and more.

- Commitment to Quality: We strictly adhere to ISO9001 standards, ensuring every product meets international requirements.

- Customization Options: We offer OEM and ODM services, allowing customers to specify custom sizes, shapes, and compositions for their heating elements.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. supports custom processing services, allowing our clients to tailor SiC heating elements according to their specific needs. Whether it is the size, shape, or power capacity, our R&D and manufacturing teams work closely with customers to deliver precise and high-performing products.

|

|

-

What is the maximum temperature that SiC heating elements can operate at? SiC heating elements can operate at temperatures as high as 1600°C.

-

Can I customize the size and shape of the heating elements? Yes, we provide custom sizes, shapes, and configurations based on customer requirements.

-

How long do SiC heating elements last? The lifespan depends on the operating conditions, but typically these elements can last several thousand hours under normal use.

-

Do you offer technical support for installation? Yes, we provide full technical support and guidance for installation and operation.

-

What are the lead times for custom orders? Custom orders typically take 4-6 weeks depending on complexity and quantity.

Contact Us

Are you ready to experience high-quality Type SiC heating elements? Contact Shaanxi Peakrise Metal Co., Ltd. today at info@peakrisemetal.com to discuss your specific requirements. We look forward to serving your needs and establishing a long-term partnership.