spiral sic heater elements

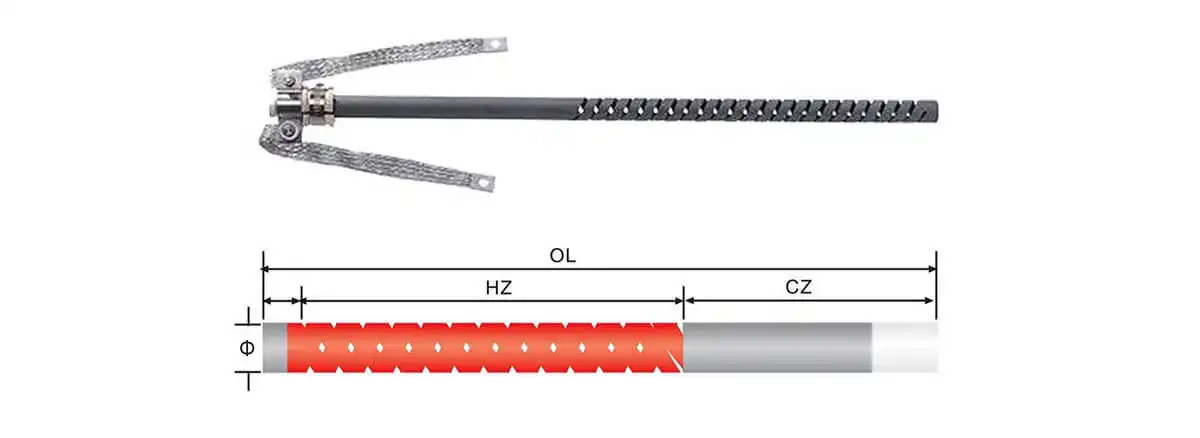

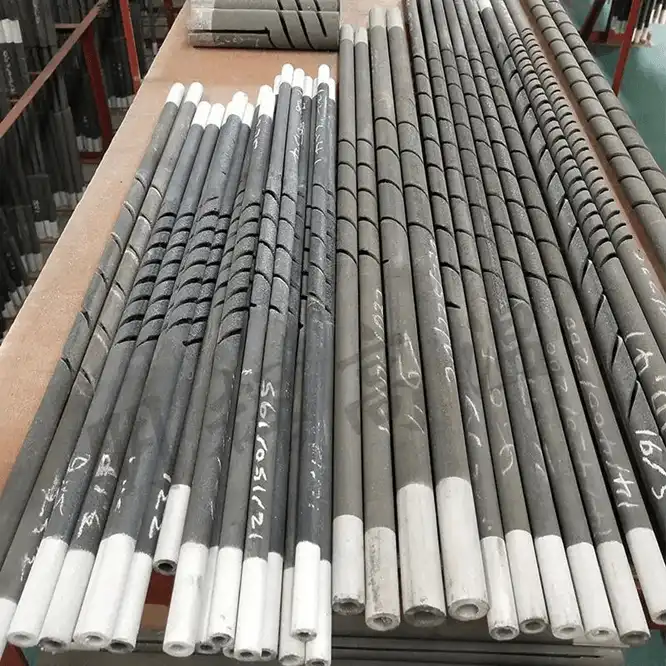

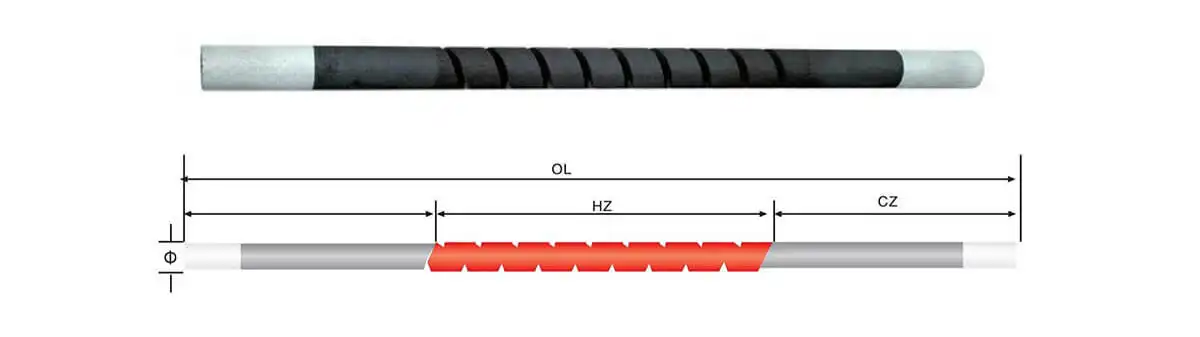

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

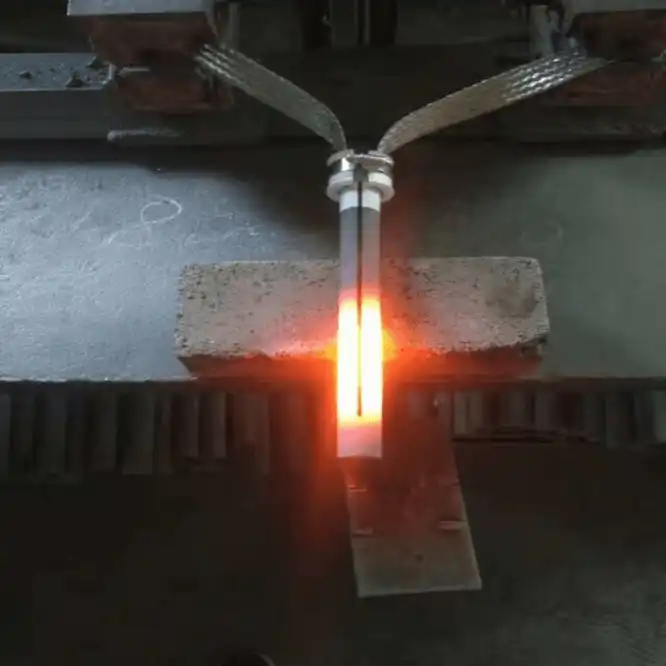

Product Introduction: Spiral SiC Heater Elements

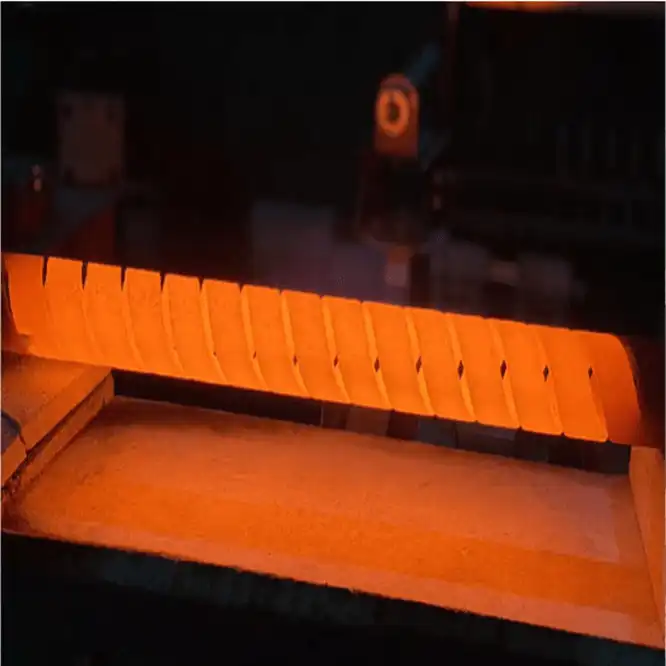

Spiral Silicon Carbide (SiC) heater elements are one of the most efficient and reliable high-temperature heating solutions available in today's industrial landscape. Known for their exceptional resistance to oxidation and high-temperature operation, these elements are widely used in various industries such as metallurgy, ceramics, and glass production. Their robust construction and ability to operate in extremely high temperatures make them ideal for demanding applications that require precise thermal management.

At Shaanxi Peakrise Metal Co., Ltd., we take pride in being a trusted supplier of spiral SiC heater elements, providing our global clientele with high-quality products backed by years of expertise. Our spiral SiC heater elements are designed to offer superior performance, energy efficiency, and extended service life, making them the preferred choice for industries that demand high reliability and precision. With decades of experience in producing non-ferrous metals and refractory products, our company has expanded its product line to meet the growing needs of international markets, exporting to countries such as the United States, Germany, South Korea, and more. As a global supplier, we understand the importance of delivering products that exceed customer expectations in terms of both quality and performance.

|

|

Product Parameters Table

| Diameter(mm) | Nominal loading ( at 1050℃ ) | |||

| Hot Zone | Cold Zone | |||

| Ω/mm | W/mm | Ω/mm | W/mm | |

| 14 | 0.02567 | 6.59 | 0.0045 | 0.3 |

| 16 | 0.02094 | 7.54 | 0.00387 | 0.5 |

| 18 | 0.01948 | 8.43 | 0.00312 | 0.55 |

| 20 | 0.01677 | 9.42 | 0.00291 | 0.6 |

| 25 | 0.01365 | 11.78 | 0.00174 | 0.93 |

| 30 | 0.0102 | 14.13 | 0.0012 | 0.95 |

| 35 | 0.00669 | 16.49 | 0.00096 | 0.98 |

| 40 | 0.00624 | 18.84 | 0.00072 | 1 |

| 45 | 0.00546 | 20.91 | 0.00066 | 1.02 |

| Diameter(mm) | Nominal loading ( at 1050℃ ) | |||

| Hot Zone | Cold Zone | |||

| Ω/mm | W/mm | Ω/mm | W/mm | |

| 18 | 0 .02158 | 8.48 | 0.0043 | 1.7 |

| 20 | 0.02302 | 9.42 | 0.00384 | 1.6 |

| 25 | 0.01969 | 11.78 | 0.00328 | 1.75 |

| 30 | 0.01523 | 14.13 | 0.0019 | 1.75 |

| 35 | 0.01224 | 16.49 | 0.0015 | 2 |

| 40 | 0.00905 | 18.48 | 0.001 | 2.1 |

| 45 | 0.0096 | 20.91 | 0.00079 | 2.1 |

| 54 | 0.00636 | 25.43 | 0.00073 | 2.3 |

Physical and Mechanical Properties

- Thermal Stability: Spiral SiC heater elements can withstand temperatures up to 1,600°C, maintaining stability even in fluctuating temperature environments.

- Oxidation Resistance: These elements possess excellent resistance to oxidation, ensuring longevity in high-temperature atmospheres.

- Mechanical Strength: With high fracture toughness and tensile strength, these heaters are designed to handle mechanical stress during installation and operation.

- Corrosion Resistance: The high-purity SiC material resists corrosive environments, allowing operation in settings exposed to chemicals or harsh conditions.

Product Functions

- Efficient Heat Transfer: The spiral design maximizes surface area, ensuring rapid heat transfer and uniform temperature distribution across the heating zone.

- Long Service Life: Spiral SiC elements offer a prolonged service life due to their high resistance to oxidation and mechanical wear.

- Energy Efficiency: These heaters are designed to achieve high energy efficiency with minimal heat loss, lowering operating costs for industrial users.

- High Thermal Conductivity: The unique properties of SiC allow for superior thermal conductivity, ensuring fast ramp-up times and reliable temperature control.

- Customizable Design: The spiral configuration can be customized in length, diameter, and power capacity, tailored to meet specific operational requirements.

|

|

Product Applications

- Metallurgy: Spiral SiC heater elements are widely used in metal melting and processing furnaces, particularly in the production of aluminum, copper, and steel alloys.

- Ceramics and Glass: These elements provide the precise temperature control required for sintering, glazing, and glass molding processes, ensuring high-quality output.

- Heat Treatment: In heat treatment furnaces, spiral SiC heaters maintain consistent, high temperatures necessary for hardening, tempering, and annealing of materials.

- Semiconductor Industry: They are used in diffusion furnaces and other high-temperature processes required in semiconductor fabrication.

- Chemical Processing: Their resistance to corrosive environments makes them ideal for chemical processing plants, where they heat corrosive fluids and gases.

- Environmental Testing: Due to their ability to withstand extreme temperatures, spiral SiC heaters are used in environmental chambers to simulate high-heat conditions for material testing.

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a state-of-the-art manufacturing facility equipped with advanced production equipment, including vacuum arc melting furnaces, sintering furnaces, and plasma welding systems. Our factory follows ISO 9001 quality management standards, ensuring that every product meets international standards. With a strong focus on research and development, we continually invest in new technologies and processes to maintain our competitive edge in the global market.

|

|

Logistics and Packaging

- Wooden Packaging: Ideal for long-distance shipments, providing maximum protection against physical damage.

- Carton Packaging: Lightweight and cost-effective for smaller, domestic shipments.

- Foam-Filled Packaging: Ensures delicate components are cushioned and protected during transit.

- Waterproof and Moisture-Proof Packaging: Necessary for shipments to regions with high humidity or exposure to moisture.

- Custom Packaging: Available for customers with specific shipping or handling requirements, ensuring safe and efficient delivery.

|

|

Logistics:

- Sea Freight: Cost-effective for bulk orders with extended delivery times.

- Air Freight: For urgent shipments requiring fast delivery to global destinations.

- Land Freight: Suitable for regional deliveries across continents.

- Multimodal Transport: Combining sea, air, and land freight for flexible and cost-efficient solutions.

- Courier Services: For small, high-priority packages requiring door-to-door delivery.

Why Choose Us

- Extensive Industry Experience: With over a decade of experience in non-ferrous metal production, Shaanxi Peakrise Metal Co., Ltd. has a proven track record of delivering high-quality products.

- Comprehensive Product Range: We offer over 100 types of products, including tungsten, molybdenum, tantalum, and other alloys.

- Global Reach: Our products are exported to numerous countries, with long-term partnerships established across Europe, Asia, and the Americas.

- State-of-the-Art Facilities: Our factory is equipped with the latest manufacturing and testing equipment, ensuring consistent quality and reliability.

- ISO 9001 Certified: We adhere to international quality management standards, guaranteeing that our products meet the strictest requirements.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers flexible OEM and ODM services to meet the specific needs of our customers. Whether you require custom sizes, unique designs, or specific material properties, we have the capabilities to deliver tailored solutions.

- What is the maximum temperature the spiral SiC heater elements can withstand?

- Our spiral SiC heater elements can operate at temperatures up to 1,600°C.

- Do you offer custom sizes for heater elements?

- Yes, we provide custom lengths, diameters, and power capacities based on customer requirements.

- How long do spiral SiC heater elements last?

- Under normal operating conditions, these elements have a typical service life of 2,000 to 4,000 hours.

- What is your lead time for international orders?

- Lead times vary depending on the order size and destination, but we typically ship within 2-4 weeks for most orders.

- Do you provide technical support for installation?

- Yes, we offer comprehensive technical support, including installation guidance and troubleshooting.

For more information or to place an order for our high-quality spiral SiC heater elements, please contact Shaanxi Peakrise Metal Co., Ltd. at info@peakrisemetal.com. We welcome global buyers and are committed to providing exceptional service and products tailored to your needs