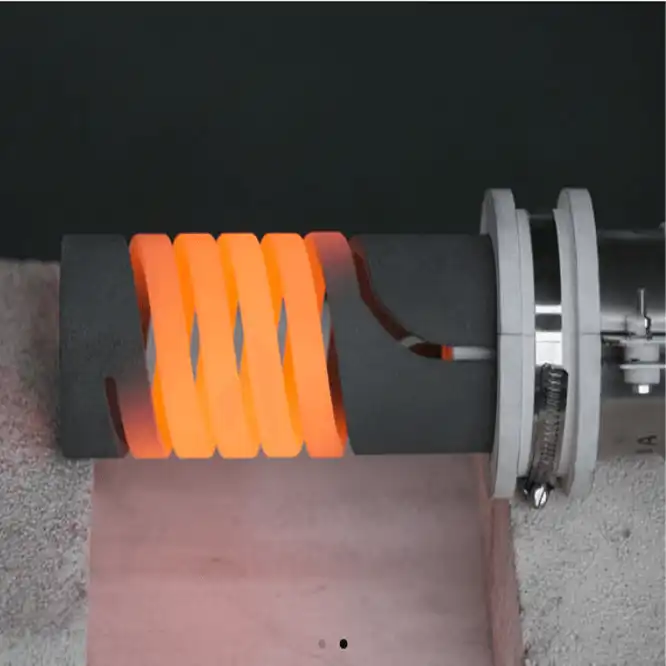

spiral sic heater element Silicon Carbide Heating Element supplier

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

Spiral SiC Heater Element - Product Introduction

At Shaanxi Peakrise Metal Co., Ltd., we take pride in being a trusted global supplier of Spiral SiC (Silicon Carbide) Heater Elements, designed for high-temperature applications across various industries. Our SiC heater elements offer outstanding thermal conductivity, electrical resistance, and durability, making them an essential component for heat treatment furnaces, kilns, and high-temperature processes. These spiral elements are ideal for providing efficient and consistent heat in harsh environments, with a unique spiral shape that enhances heat distribution and increases the operational lifespan. With nearly a decade of experience, we manufacture high-quality Spiral SiC Heater Elements, delivering exceptional performance to our global customers. As a leading non-ferrous metal producer, we combine cutting-edge technology with extensive expertise to meet your customized requirements.

|

|

Product Parameters Table

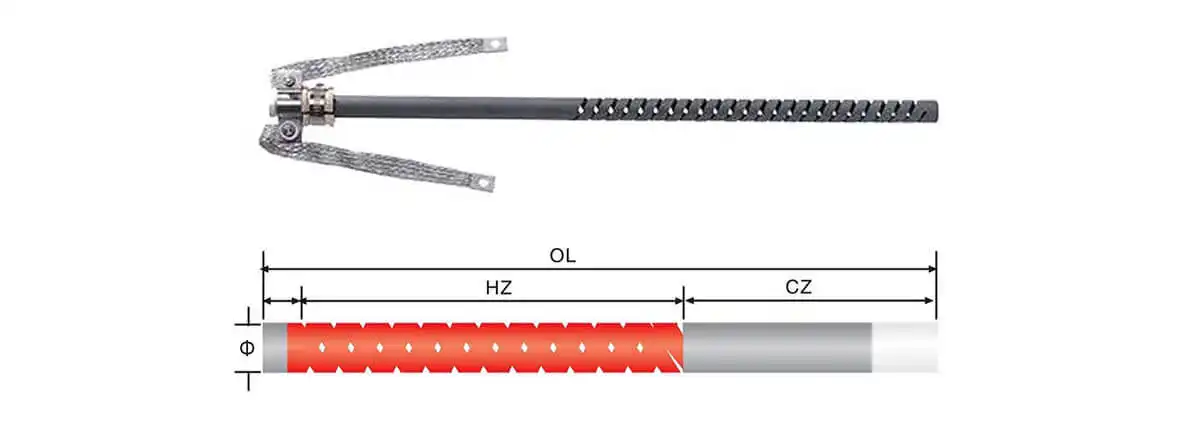

1. Double helix silicon carbide heating element

| Diameter(mm) | Nominal loading ( at 1050℃ ) | |||

| Hot Zone | Cold Zone | |||

| Ω/mm | W/mm | Ω/mm | W/mm | |

| 18 | 0 .02158 | 8.48 | 0.0043 | 1.7 |

| 20 | 0.02302 | 9.42 | 0.00384 | 1.6 |

| 25 | 0.01969 | 11.78 | 0.00328 | 1.75 |

| 30 | 0.01523 | 14.13 | 0.0019 | 1.75 |

| 35 | 0.01224 | 16.49 | 0.0015 | 2 |

| 40 | 0.00905 | 18.48 | 0.001 | 2.1 |

| 45 | 0.0096 | 20.91 | 0.00079 | 2.1 |

| 54 | 0.00636 | 25.43 | 0.00073 | 2.3 |

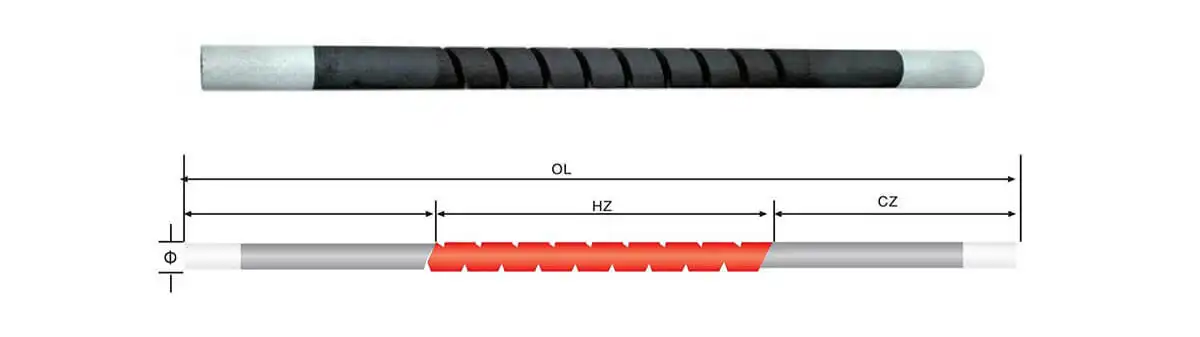

2.Single helical silicon carbide heating element

| Diameter(mm) | Nominal loading ( at 1050℃ ) | |||

| Hot Zone | Cold Zone | |||

| Ω/mm | W/mm | Ω/mm | W/mm | |

| 14 | 0.02567 | 6.59 | 0.0045 | 0.3 |

| 16 | 0.02094 | 7.54 | 0.00387 | 0.5 |

| 18 | 0.01948 | 8.43 | 0.00312 | 0.55 |

| 20 | 0.01677 | 9.42 | 0.00291 | 0.6 |

| 25 | 0.01365 | 11.78 | 0.00174 | 0.93 |

| 30 | 0.0102 | 14.13 | 0.0012 | 0.95 |

| 35 | 0.00669 | 16.49 | 0.00096 | 0.98 |

| 40 | 0.00624 | 18.84 | 0.00072 | 1 |

| 45 | 0.00546 | 20.91 | 0.00066 | 1.02 |

Physical and Mechanical Properties

- High thermal conductivity: Enables the heater to reach high temperatures quickly and efficiently.

- Excellent electrical resistance: Ensures stable operation even in variable temperature conditions.

- Durable construction: Withstands harsh industrial environments, providing a longer operational lifespan.

- Resistance to oxidation and corrosion: The SiC material is inherently resistant to chemical corrosion and oxidation at elevated temperatures.

- Consistent heating performance: The spiral design promotes uniform heat distribution, critical for applications requiring precise temperature control.

Product Applications

- Heat Treatment Furnaces: Used in industries like steel and metalworking, where precise temperature control is critical.

- Glass Production: Ensures even heating and high-quality glass products by providing consistent, controllable heat.

- Ceramic Manufacturing: In kilns and furnaces, SiC elements provide uniform heat, essential for high-quality ceramic goods.

- Semiconductor Industry: Used in processes that require stable and precise high temperatures.

- Laboratory and Research Facilities: Offers reliable heating solutions for high-temperature research and testing.

|

|

Product Process and Production Flow

Our Spiral SiC Heater Elements are manufactured using state-of-the-art equipment, including intermediate frequency sintering furnaces and vacuum arc melting furnaces. The production process includes:

- Material Selection: We source high-purity silicon carbide.

- Shaping and Sintering: The elements are shaped into their spiral form, followed by high-temperature sintering to achieve their robust structure.

- Quality Control: Each heater element undergoes rigorous testing to ensure durability and thermal efficiency before being shipped.

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates in a modern facility equipped with advanced machinery, including vacuum annealing furnaces, CNC machines, and plasma electron beam melting furnaces. With our integrated R&D and testing labs, we ensure that all products meet international standards. Our factory’s capabilities enable us to meet the unique demands of industries requiring high-performance heating elements.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Wooden Crate Packaging: For heavy-duty protection during transportation.

- Carton Packaging: For smaller, lightweight shipments.

- Foam-Filled Packaging: To ensure that the products remain secure and protected against impact.

- Waterproof and Moisture-Proof Packaging: For sensitive shipments.

- Customized Packaging: Tailored to meet client-specific needs.

- International Standard Packaging: Compliant with export standards, ensuring safe and secure delivery.

|

|

Why Choose Us

- Extensive Expertise: We are experienced in producing a wide range of non-ferrous metal products, including tungsten, molybdenum, and tantalum.

- Advanced Technology: Our modern production facilities and equipment ensure consistent product quality.

- Custom Manufacturing: We offer OEM and ODM services to meet your specific needs.

- Global Reach: Our products are exported to markets worldwide, including the U.S., Germany, and Australia.

- Commitment to Quality: We adhere to strict quality control standards and are ISO 9001 certified.

- Customer Satisfaction: We have built long-term relationships with clients through excellent service and product performance.

FAQ

- What is the maximum operating temperature of the Spiral SiC Heater Element?

- Our elements can operate at temperatures up to 1,600°C.

- Can the heater elements be customized?

- Yes, we offer custom lengths, diameters, and resistance values to fit your specific needs.

- What industries commonly use Spiral SiC Heater Elements?

- They are widely used in steel, glass, ceramics, and semiconductor manufacturing.

- What is the typical lifespan of these heater elements?

- With proper maintenance, our heater elements have a long operational lifespan, even in harsh environments.

- How do you ensure product quality?

- Each product undergoes stringent testing, and we follow ISO 9001 standards for quality control.

Contact Us

Ready to upgrade your heating solutions with high-performance Spiral SiC Heater Elements? Contact us today at info@peakrisemetal.com to learn more about how Shaanxi Peakrise Metal Co., Ltd. can meet your industrial heating needs. Let’s work together to achieve your production goals!