GD type sic rod heating element

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

Product Introduction

The GD-type SiC rod heating element is a specific variant of silicon carbide heating elements, often referred to as a "Guarded" or Double-spiral heating element. This type is designed for applications that require robust performance, uniform heating, and extended service life in high-temperature environments.

|

Product Parameters Table

| Specification | Value | Unit |

|---|---|---|

| Maximum Operating Temperature | 1600 | °C |

| Diameter Range | 6-60 | mm |

| Length Range | 300-2000 | mm |

| Electrical Resistance | 0.1-50 | Ohm |

| Density | 2.6-2.7 | g/cm³ |

| Parameter | Value | Unit |

|---|---|---|

| Operating Voltage | 20-300 | V |

| Current Load Capacity | 5-100 | A |

| Thermal Conductivity | 120-130 | W/m·K |

| Surface Load | 6-10 | W/cm² |

| Characteristic | Value | Unit |

|---|---|---|

| Oxidation Resistance | High | |

| Thermal Shock Resistance | Excellent | |

| Durability at 1500°C | 2000+ | hours |

| Cold End Resistance | 10-30% |

|

|

Physical and Mechanical Properties

SiC rod heating elements are known for their superior mechanical properties and physical resilience. The key characteristics include:

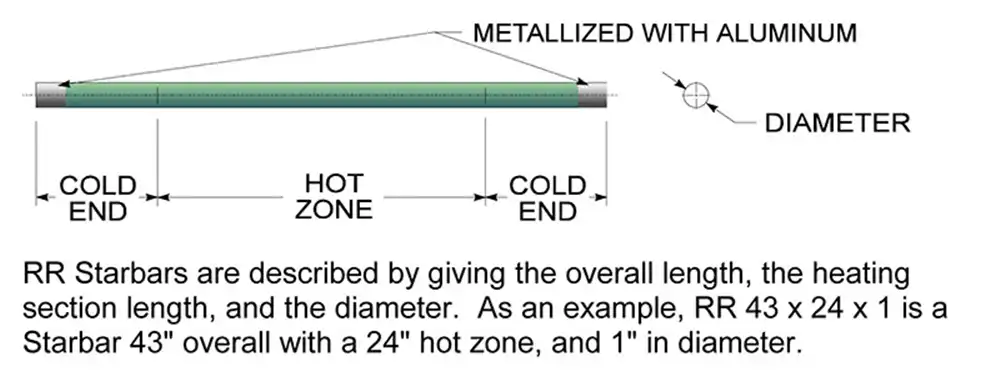

- Double Spiral Structure:

The GD type consists of a straight SiC rod with a double spiral cut in the center section of the heating element. This spiral design increases the effective heating surface, enhancing efficiency and uniformity of heat distribution.

The cold ends (non-heating sections) are often protected or "guarded," minimizing heat loss and providing greater control over the heated zone.

- Operating Temperatures:

Like other SiC elements, the GD-type can operate at temperatures up to 1600°C (2912°F) in air or even higher in controlled atmospheres.

- Durability:

The element is highly resistant to oxidation and degradation, ensuring a longer lifespan even in extreme conditions like oxidizing atmospheres, corrosive environments, or high-temperature furnaces.

- Versatile Heating:

The GD design allows for stable, uniform heating and is typically used in applications where even temperature distribution is critical.

- High Density:

Due to the design, GD-type SiC elements provide high power output and can handle high power density applications.

- Power Supply & Configuration:

The GD-type elements usually require AC power. They can be connected in a series or parallel arrangement, depending on the furnace design and power supply specifications.

Product Functions

Reduced Cold End Heating: The guarded design of the cold ends helps avoid unnecessary heat in the connecting areas, which reduces wear and power loss.

Uniform Heat Distribution: The double spiral design promotes even heat distribution across the heating zone.

Long Service Life: High resistance to oxidation, corrosion, and thermal shock prolongs the service life in industrial environments.

Product Applications

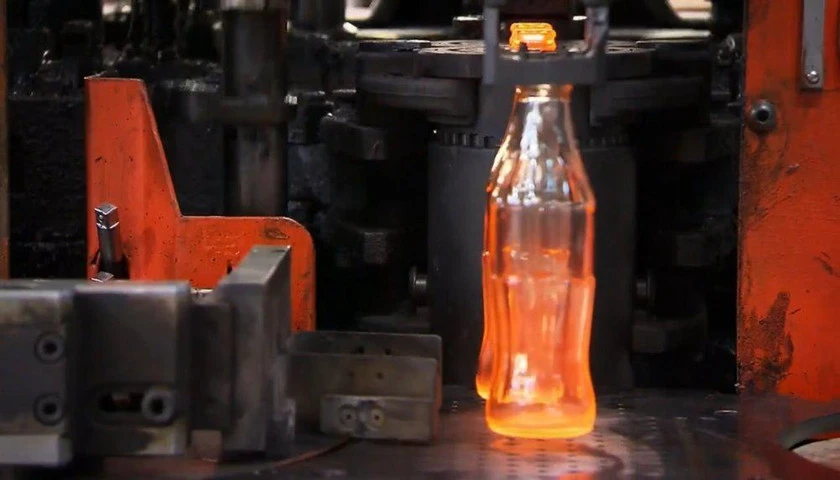

- Glass Manufacturing: Used in glass furnaces for melting and refining glass.

- Ceramics Processing: For sintering, firing, and heat treatment of ceramics.

- Heat Treatment: For annealing, tempering, and sintering in high-temperature industrial furnaces.

- Metal Processing: Used in metallurgical furnaces for sintering, melting, and casting metals.

- Laboratory Furnaces: Ideal for laboratory setups that need precise, consistent high temperatures.

|

|

Product Process and Production Flow

Our SiC rod heating elements undergo a rigorous manufacturing process, ensuring the highest quality standards at every stage:

- Material Selection: Premium silicon carbide powder is selected for its purity and performance characteristics.

- Shaping and Forming: The SiC material is molded into the desired rod shape using specialized equipment to ensure uniformity and accuracy.

- Sintering: The rods are sintered in a high-temperature furnace to enhance their strength and thermal properties.

- Surface Treatment: A final treatment is applied to ensure resistance to oxidation and corrosion.

- Quality Control: Each SiC rod heating element is tested for electrical resistance, thermal conductivity, and dimensional accuracy before leaving the factory.

Our Factory

At Shaanxi Peakrise Metal Co., Ltd., we take pride in our state-of-the-art manufacturing facilities. Equipped with advanced machinery like intermediate frequency sintering furnaces and plasma welding rooms, we are capable of producing SiC rod heating elements that meet the highest industry standards. Our factory is ISO 9001-certified, and we implement strict quality control measures at every step of production to ensure consistent product excellence.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

We offer a range of packaging options to ensure safe delivery of your SiC rod heating elements:

- Wooden crates for large shipments

- Foam-filled cartons to prevent damage during transit

- Waterproof and moisture-proof packaging for added protection

- Custom packaging solutions available upon request

- All packaging meets international shipping standards

We also provide flexible shipping options, including:

- Sea freight for bulk orders

- Air freight for urgent deliveries

- Land transport for regional shipments

- Multimodal transport services for complex logistics needs

- Express courier services for smaller, high-priority shipments

|

|

Why Choose Us

- Expertise: Over a decade of experience in the non-ferrous metal industry.

- Quality Assurance: ISO 9001-certified factory with stringent quality control.

- Customization: OEM and ODM services to meet your specific requirements.

- Global Reach: We have established long-term relationships with clients across the globe, providing consistent quality and service.

- Advanced Equipment: Our modern manufacturing capabilities ensure precision and efficiency.

FAQ

-

What is the maximum temperature SiC rod heating elements can withstand?

- Our SiC rods can operate at temperatures up to 1600°C.

-

Are these elements resistant to oxidation?

- Yes, the SiC material provides excellent oxidation resistance, ensuring long-lasting performance in high-temperature environments.

-

Can you customize the size and electrical resistance of the elements?

- Yes, we offer full customization services to meet your specific needs.

-

What is the typical lifespan of an SiC rod heating element?

- Under normal operating conditions, our SiC rods can last for thousands of hours.

-

What packaging options are available?

- We offer wooden crates, foam-filled cartons, and waterproof packaging options that meet international shipping standards.

Contact Us

For more information on our SiC rod heating elements or to place an order, feel free to reach out to us at info@peakrisemetal.com. We look forward to collaborating with global purchasers and providing high-quality heating solutions for your industry.