Nickel melting crucible

Grade: NO2200

Shape: Crucible

Type: Low Form Ni Crucible, Flanged Rims Ni Crucible,straight Wall Ni Crucible, Tapered Ni Crucible, Cylindrical Ni Crucible

Density: 8.9g/cm3

Size: 5ml,10ml,15ml,25ml,30ml,35ml,40ml,45ml Etc.

Custom: Yes

MOQ: 5pcs

Application: Molten ferroalloys, slag, clay, refractory materials

PRODUCT DESCRIPTION

Nickel Melting Crucible Product Introduction

At Shaanxi Peakrise Metal Co., Ltd., we are proud to be a trusted supplier of nickel melting crucibles, which are essential for industries that demand high-performance materials in extreme conditions. Our nickel crucibles are widely recognized for their superior corrosion resistance, thermal stability, and longevity, making them a top choice in sectors such as metallurgy, chemical processing, and research laboratories.

Nickel crucibles are designed to withstand high temperatures and are used for melting and refining nickel and nickel alloys. They are ideal for laboratory applications where purity and precision are critical, ensuring that your materials remain uncontaminated during the melting process. Whether you’re working with complex alloys or pure nickel, our crucibles provide the reliability and performance you need.

Shaanxi Peakrise Metal Co., Ltd. is an experienced manufacturer and supplier of nickel melting crucibles, with a strong reputation for delivering high-quality non-ferrous metal products to customers worldwide. With years of expertise in manufacturing nickel-based alloys, we offer tailored solutions that meet the exact specifications of our global clients.

|

|

Product Parameters Table

Below are the key technical specifications for our nickel melting crucibles. All values are accurate and verified by our quality assurance team:

| Parameter | Value |

|---|---|

| Material Composition | Pure Nickel (99.6% minimum) |

| Melting Point | 1453°C |

| Density | 8.9 g/cm³ |

| Maximum Operating Temperature | 1200°C |

| Thermal Conductivity | 91 W/m·K |

| Parameter | Value |

|---|---|

| Crucible Capacity | 100 mL to 10,000 mL |

| Wall Thickness | 1.5 mm to 5 mm |

| Inner Diameter | 30 mm to 200 mm |

| Height | 50 mm to 300 mm |

| Weight | 0.2 kg to 5 kg |

| Parameter | Value |

|---|---|

| Corrosion Resistance | Excellent in acidic environments |

| Electrical Conductivity | 13.8 MS/m |

| Heat Treatment | Annealed |

| Tensile Strength | 380 MPa |

| Elongation at Break | 45% |

Physical and Mechanical Properties

Nickel melting crucibles exhibit excellent physical and mechanical properties, which make them suitable for high-temperature applications. The thermal stability and corrosion resistance of nickel ensure that the crucibles can be used repeatedly in harsh environments. Additionally, their high tensile strength and elongation capacity prevent deformation under extreme stress.

- Thermal Stability: Nickel melting crucibles can operate at temperatures up to 1200°C without losing their structural integrity, making them ideal for demanding processes.

- Corrosion Resistance: The high nickel content gives these crucibles excellent resistance to corrosion, especially in acidic and oxidizing environments.

- Durability: With a high tensile strength and elongation capacity, these crucibles are resistant to cracking and deformation, providing long service life even under extreme conditions.

|

|

Product Functions

Our nickel melting crucibles offer a range of essential functions that are critical for industries where precision and material integrity are paramount. Each function is directly related to the unique properties of nickel:

- High-Temperature Melting: Nickel crucibles are designed to melt nickel, nickel alloys, and other high-temperature metals with excellent thermal stability.

- Corrosion Resistance: Suitable for environments where the crucible is exposed to aggressive chemicals or corrosive materials.

- Uniform Heat Distribution: The high thermal conductivity of nickel ensures that heat is evenly distributed, minimizing the risk of hotspots that can affect the melting process.

- Purity Assurance: Nickel crucibles maintain material purity, ensuring no contamination during the melting process, making them perfect for applications in laboratories and research.

Product Applications

Nickel melting crucibles are used across various industries due to their durability and high resistance to extreme conditions. Here are some key applications:

- Metallurgy: Used in melting and refining nickel and nickel-based alloys, ensuring material purity during the smelting process.

- Chemical Processing: Crucial for handling high-temperature reactions that involve corrosive chemicals.

- Laboratory Research: Common in research laboratories for melting high-purity nickel and its alloys, ensuring consistent experimental results.

- Glass Manufacturing: Suitable for processes that involve glass melting where contamination from other metals is a concern.

- Aerospace Industry: Used in the production of nickel-based superalloys that are critical in aerospace engineering.

|

|

Product Process and Production Flow

At Shaanxi Peakrise Metal Co., Ltd., we follow a rigorous production process to ensure the highest quality nickel crucibles:

- Material Sourcing: We source premium-grade nickel that meets the strictest international standards.

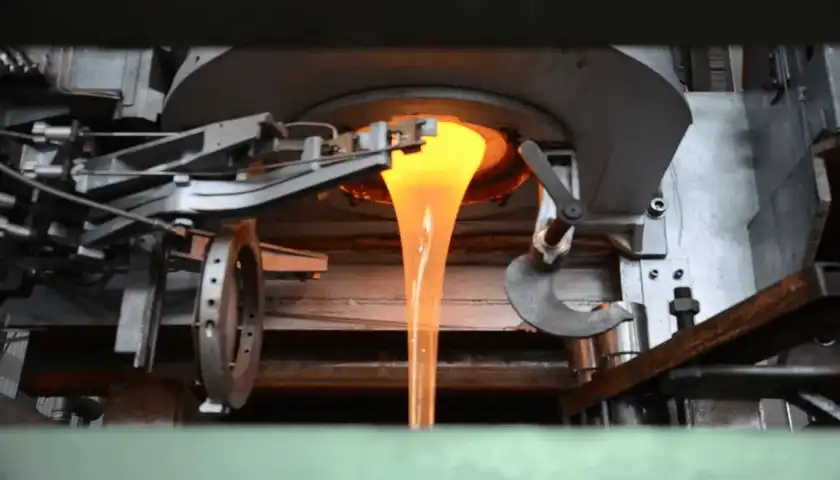

- Melting and Casting: The nickel is melted in our state-of-the-art vacuum arc melting furnaces, ensuring purity and uniformity.

- Forming: The molten nickel is cast into crucibles using precision molds, followed by machining to achieve the exact dimensions required by the customer.

- Annealing: The crucibles undergo heat treatment to enhance their mechanical properties and corrosion resistance.

- Inspection and Testing: Each crucible is inspected for dimensional accuracy, surface finish, and mechanical properties, ensuring they meet our high-quality standards.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates from a state-of-the-art facility equipped with advanced production technologies, including vacuum arc melting furnaces, laser cutting systems, and CNC machines. Our team of engineers and technicians ensures that every crucible produced meets stringent quality control measures. With a focus on innovation, we continue to invest in research and development to enhance our product offerings and meet the evolving needs of our customers.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging:

We offer flexible packaging options to ensure the safe delivery of our products:

- Wooden crate packaging: Provides excellent protection for large crucibles during international shipping.

- Foam-filled cartons: Ideal for smaller crucibles, preventing any movement or impact during transit.

- Custom packaging: Tailored to meet specific customer needs.

- Sea freight

- Air freight

- Land transport

- Multimodal transport

- Express courier services

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Expertise: Over a decade of experience in producing high-quality nickel and other non-ferrous metal products.

- Advanced Technology: We use cutting-edge equipment like vacuum arc melting furnaces to ensure product quality.

- Global Reach: Our products are exported to multiple countries, including the US, South Korea, and Germany.

- Customer Satisfaction: We have a proven track record of delivering products that meet and exceed customer expectations.

- Customization: We provide OEM/ODM services to meet the unique specifications of our clients.

OEM Services

We understand that different projects require different specifications, and that’s why we offer custom nickel crucibles tailored to your specific requirements. Whether you need a unique size, shape, or alloy composition, we provide OEM/ODM services to ensure that your needs are fully met.

-

What is the maximum temperature a nickel crucible can handle?

Our nickel crucibles can withstand temperatures up to 1200°C. -

Can I order custom-sized nickel crucibles?

Yes, we offer custom OEM services to meet your exact specifications. -

What industries typically use nickel crucibles?

Nickel crucibles are commonly used in metallurgy, chemical processing, laboratories, and aerospace. -

How do you ensure the quality of your nickel crucibles?

Every crucible undergoes rigorous testing for material purity, thermal stability, and dimensional accuracy. -

What packaging options are available?

We offer wooden crates, foam-filled cartons, and custom packaging to ensure safe delivery.

Contact Us

If you are looking for high-quality nickel melting crucibles, we invite you to get in touch with us. Our team at Shaanxi Peakrise Metal Co., Ltd. is ready to meet your needs with tailored solutions. Contact us today at info@peakrisemetal.com to learn more about our products and services.

We look forward to working with you!