U type MoSi2 heating elements

Type: U shape,Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Molybdenum silicide

Size: Φ3/6、Φ4/9、Φ6/12、Φ9/18、Φ12/24 Etc.

Density: 5.6~5.8g/cm3

Use Temperature: 1300~1800℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

Product Introduction: SiC MoSi2 Heating Elements by Shaanxi Peakrise Metal Co., Ltd.

Shaanxi Peakrise Metal Co., Ltd. is a trusted global supplier of silicon carbide (SiC) and molybdenum disilicide (MoSi2) heating elements, providing high-performance solutions to various industries requiring extreme temperature applications. Our SiC and MoSi2 heating elements offer superior electrical conductivity, oxidation resistance, and mechanical strength at high temperatures, making them essential for high-temperature furnaces, kilns, and other thermal processing applications. These heating elements are known for their efficient performance, long service life, and energy-saving properties, providing an optimal solution for industries like metallurgy, ceramics, glass, and semiconductor production.

As a leading supplier, Shaanxi Peakrise Metal Co., Ltd. delivers not only premium quality but also the capacity to meet the growing demands of global markets. With decades of experience in the production and export of non-ferrous metals, we ensure that our SiC and MoSi2 heating elements are produced to the highest industry standards. Our extensive research and development, combined with advanced production technology, position us as a reliable partner for customers worldwide.

|

|

Product Parameters Table

| Parameter | SiC Heating Elements | MoSi2 Heating Elements |

|---|---|---|

| Maximum Temperature | 1600°C | 1800°C |

| Electrical Resistivity | 0.1-0.4 Ω·cm | 0.1-0.3 Ω·cm |

| Density | 3.1 g/cm³ | 5.6 g/cm³ |

| Melting Point | 2700°C | 2030°C |

| Thermal Conductivity | 120 W/m·K | 25 W/m·K |

| Flexural Strength | 400 MPa | 200 MPa |

| Oxidation Resistance | Excellent | Superior at high temperatures |

| Size (mm) | SiC Heating Elements | MoSi2 Heating Elements |

|---|---|---|

| Length | 200-1800 mm | 300-1800 mm |

| Diameter | 6-54 mm | 3-12 mm |

| Heater Zone Length | 100-1600 mm | 200-1600 mm |

| Cold End Length | 50-250 mm | 50-250 mm |

| Performance | SiC Heating Elements | MoSi2 Heating Elements |

|---|---|---|

| Heating Efficiency | High | Very High |

| Resistance to Thermal Shock | Moderate | Excellent |

| Typical Applications | Kilns, Furnaces, Heat Treatment | Glass, Ceramics, Metallurgy |

| Power Consumption | 1-50 kW | 1-30 kW |

Physical and Mechanical Properties

- SiC Heating Elements: Known for their high thermal conductivity and stability, SiC elements perform well in oxidizing and reducing environments. They have high mechanical strength and good wear resistance.

- MoSi2 Heating Elements: These elements are ideal for high-temperature environments, providing excellent oxidation resistance and low thermal expansion. MoSi2 heating elements also have a self-healing protective oxide layer, which significantly enhances their lifespan in oxygen-containing atmospheres.

Product Functions

- Temperature Control: Both SiC and MoSi2 heating elements are designed to operate in extreme temperatures, providing precise and stable thermal control.

- Energy Efficiency: SiC and MoSi2 heating elements offer high energy efficiency, reducing overall operational costs in industrial heating processes.

- Durability: The materials used for these elements exhibit excellent resistance to corrosion, oxidation, and thermal shock, ensuring longer lifespans and reduced maintenance requirements.

- Uniform Heating: These elements provide uniform heat distribution across large surface areas, making them ideal for large-scale industrial applications.

|

|

Product Applications

- Metallurgical Industry: SiC and MoSi2 heating elements are used in heat treatment processes for hardening, annealing, and sintering metals. Their ability to withstand high temperatures makes them indispensable for metallurgical furnaces.

- Ceramics and Glass Industry: In kilns used for firing ceramics and melting glass, these elements ensure precise temperature control and energy efficiency, contributing to product quality and reduced energy costs.

- Semiconductor Manufacturing: The precise heating offered by these elements makes them ideal for silicon wafer production and other semiconductor processes that require exact temperature control.

- Laboratory Furnaces: SiC and MoSi2 elements are widely used in research laboratories for high-temperature tests and material development.

- Powder Metallurgy: The elements are critical in sintering processes for producing high-performance metal powders used in various advanced technologies.

|

|

Product Process and Production Flow

- Raw Material Selection: High-purity SiC and MoSi2 are sourced from reputable suppliers.

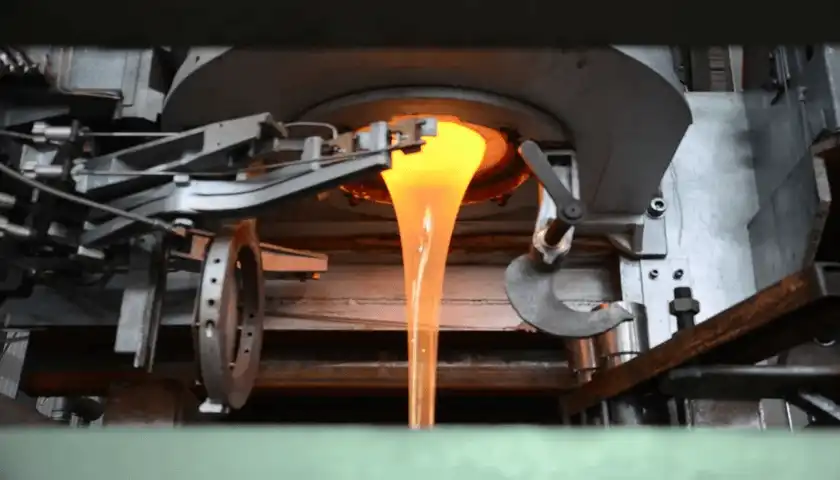

- Melting and Sintering: Materials are melted using vacuum arc melting and intermediate frequency sintering furnaces to ensure uniform material composition.

- Machining: After initial sintering, the elements are machined to precise dimensions using advanced CNC equipment.

- Quality Control: Each batch undergoes strict testing for electrical resistance, mechanical strength, and oxidation resistance.

- Final Inspection and Packaging: A comprehensive inspection is performed before packaging to ensure that all elements meet customer specifications.

Our Factory

Shaanxi Peakrise Metal Co., Ltd. boasts a state-of-the-art production facility equipped with advanced machinery, including vacuum arc furnaces, CNC machines, and sintering furnaces. Our R&D team is constantly innovating to enhance product quality and meet evolving industry standards. With a focus on precision, we maintain a high-quality stock inventory to meet urgent orders and customization requests.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Wooden Crate Packaging: Provides robust protection for heavy and fragile components during shipping.

- Carton Packaging: Used for lighter products, ensuring ease of handling and protection.

- Foam Filling: Adds an extra layer of shock resistance for delicate parts.

- Waterproof and Moisture-Proof Packaging: Essential for overseas shipments where environmental conditions may vary.

- Custom Packaging: Tailored packaging solutions for unique customer needs.

- International Standard Packaging: Ensures that all packaging materials meet global shipping standards.

Logistics Options:

- Sea Freight: Economical for large volume orders.

- Air Freight: Ideal for urgent deliveries.

- Land Freight: Used for regional shipments.

- Multimodal Transport: Combining air, sea, and land for optimal shipping solutions.

- Courier Services: For small, urgent orders.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Decades of Experience: With over 10 years of expertise in non-ferrous metal production, we understand industry needs.

- Global Presence: Products exported to over 10 countries, establishing long-term partnerships.

- Advanced Equipment: Cutting-edge manufacturing tools ensure precise and high-quality production.

- Quality Assurance: ISO9001-certified quality control system guarantees the highest product standards.

- Customization: We offer OEM and ODM services to tailor our products to your specific needs.

- R&D Capabilities: Continuous investment in research ensures that our products meet the latest technological advancements.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM and ODM services. From custom dimensions to specific material properties, we tailor our SiC and MoSi2 heating elements to meet client requirements. Whether it’s adjusting the size, shape, or electrical specifications, our team of engineers is ready to create bespoke solutions for your business.

FAQ

- What is the maximum operating temperature for your SiC and MoSi2 heating elements?

- SiC elements can operate up to 1600°C, while MoSi2 elements can reach up to 1800°C.

- Do you offer custom-sized heating elements?

- Yes, we provide OEM services to create heating elements that meet your specific size and performance requirements.

- How long do SiC and MoSi2 heating elements last?

- With proper maintenance, these elements have a long lifespan, depending on usage conditions and environment.

- What are the main applications of your heating elements?

- Our heating elements are used in furnaces, kilns, and high-temperature industrial processes, including metallurgy and ceramics.

- What are your lead times for custom orders?

- Lead times vary depending on the order complexity, but we strive to deliver custom orders within 4-6 weeks.

Contact Us

Contact us today to learn more about how our SiC and MoSi2 heating elements can improve your industrial heating processes. Shaanxi Peakrise Metal Co., Ltd. is your trusted partner for high-quality non-ferrous metal products. For inquiries, please reach out to us at info@peakrisemetal.com. We look forward to working with you on your next project!