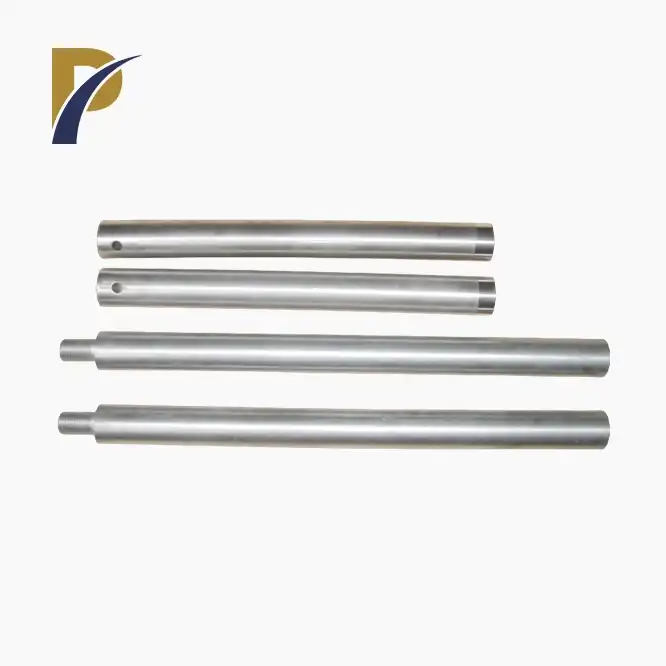

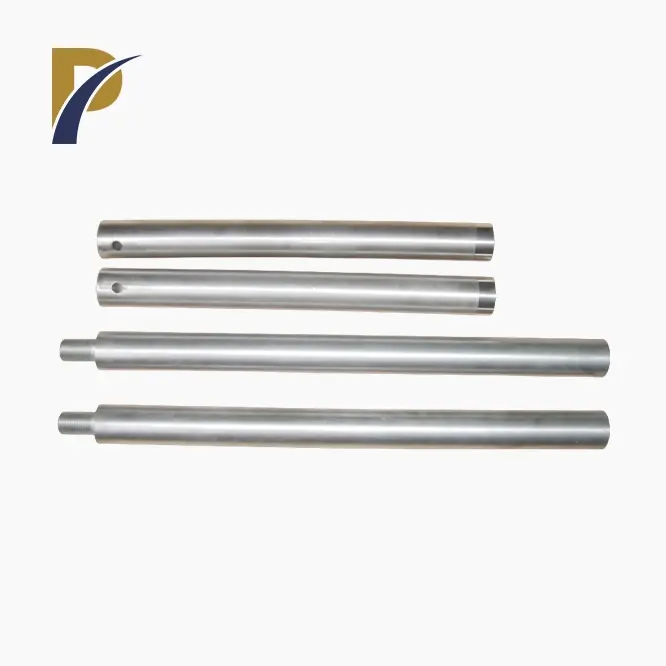

2 molybdenum electrodes 1 8 diameter 1 pair

Purity: 99.97%

Diameter: 4~120mm

Length: 200~2000mm

Surface: Polished

Standard: ASTM B387

Tensile Strength:≥900MPa

Tensile Strength:≥900MPa

Elongation: ≥15%

Application:Daily glass, optical glass, thermal insulation materials, glass fiber, rare earth industry and other fields

PRODUCT DESCRIPTION

Product Overview

PeakRiseMetal offers high-quality 2 molybdenum electrodes, 1/8 diameter, 1 pair, designed for industrial applications requiring superior conductivity, high-temperature resistance, and exceptional durability. These electrodes are manufactured from 99.97% pure molybdenum and conform to ASTM B387 standards, ensuring optimal performance in glass melting, welding, and furnace applications.

Product Specifications

| Parameter | Details |

|---|---|

| Material | Pure Molybdenum (99.97%) |

| Diameter | 1/8 inch (3.175mm) |

| Length | Customizable (Standard: 100mm - 500mm) |

| Surface Finish | Polished, Bright |

| Density | 10.2 g/cm³ |

| Melting Point | 2620°C (4748°F) |

| Standard | ASTM B387 |

| Package | Secure Plywood Case |

Applications

Our 2 molybdenum electrodes (1/8 diameter, 1 pair) are widely used in:

Glass Melting & Manufacturing: Provides stable, long-lasting performance in glass furnaces.

High-Temperature Welding: Used in TIG welding and other specialized welding applications.

Electronics & Semiconductor Industry: Essential for manufacturing semiconductor components and vacuum furnaces.

Heat Treatment Furnaces: Ideal for use in vacuum furnaces and other high-temperature heating environments.

Laboratory & Research Use: Preferred for advanced material research and high-precision applications.

Manufacturing Process

Our molybdenum electrodes are produced through a rigorous multi-step process, including:

Molybdenum Powder Selection: Sourced from high-purity molybdenum ore and refined to 99.97% purity.

Pressing & Sintering: The material is compressed under high pressure and sintered to achieve optimal density and strength.

Precision Machining: Electrodes are machined to precise diameters and surface finishes for consistency.

Quality Inspection: Each batch undergoes non-destructive testing (NDT) to ensure zero cracks, defects, or inclusions.

Features of molybdenum electrodes

High melting point, excellent conductivity, corrosion resistance, durability, high thermal conductivity, stability, efficient glass melting, reliable performance.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Precision engineered molybdenum electrodes to meet your specific needs!

At Peakrise Metal, your specific needs are our top priority. With over a decade of dedication, we expertly convert your intricate ideas into practical solutions using our precision-engineered molybdenum electrodes. From initial design to detailed specification modifications, each step of our manufacturing process is customized to fulfill your exact requirements.

The following customizations can be made when purchasing molybdenum electrodes:

- Size and shape: Customize the length, diameter and shape of the electrode according to specific application requirements to adapt to different equipment and operating conditions.

- Purity: Provide molybdenum materials with different purity levels according to customer requirements to meet the performance requirements of specific applications.

- Coating treatment: Add specific coatings to the electrode, such as anti-oxidation coating or conductive coating, to improve the performance and life of the electrode in specific environments.

- Connection method: Customize the connection method of the electrode according to the installation requirements of the equipment, such as threaded connection, flange connection, etc., to ensure convenient and stable installation.

- Packaging: Provide customized packaging solutions according to transportation and storage requirements to ensure the safety and integrity of the electrode during transportation.

Why choose molybdenum electrodes from Peakrise Metal?

At Peakrise Metal, we represent the highest industry standards through a perfect combination of advanced techniques, innovative technology, and unmatched expertise. Our steadfast commitment guarantees that your specific needs are expertly addressed with top-quality molybdenum electrode solutions.

Expertise and Experience: With over a decade in the industry, Peakrise Metal combines advanced technology and deep expertise to deliver high-quality molybdenum electrodes tailored to your precise needs.

Custom Solutions: We offer personalized solutions, including custom sizes, shapes, and coatings, ensuring our molybdenum electrodes meet the exact specifications and performance requirements of your application.

Unmatched Quality: Our commitment to superior manufacturing standards ensures that each molybdenum electrode delivers exceptional performance, durability, and reliability, providing excellent value for your investment.

Our workshop

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Our Package

|

|

|

|

|

|

|

|

|

|

Certificate

|

Quality Assurance

At PeakRiseMetal, we are committed to delivering premium-quality molybdenum electrodes that meet the highest industry standards. We conduct multiple quality checks, including dimensional accuracy tests, purity analysis, and surface integrity inspections, ensuring each electrode performs flawlessly in industrial applications.

Packaging & Delivery

Secure Packaging: Electrodes are packed in shockproof plywood cases to prevent damage during transportation.

Fast Shipping: Orders are processed within 7-10 business days, with global shipping available.

MOQ: 1 pair (custom bulk orders accepted).

Get a Quote Now!

Looking for high-performance molybdenum electrodes for your industrial needs? Contact us today for bulk pricing and custom orders!

Email: info@peakrisemetal.com WhatsApp: +8613186382597